Projects

Introduction of H-shaped Steel Laser Cutting Machine

With the rapid development of the modern construction industry, steel structure buildings stand out among various building forms. Among them, H-shaped steel laser cutting machines play a vital role in steel structure buildings. This article will introduce in detail the working principle, application scenarios, advantages and market prospects of H-shaped steel laser cutting machines.

Determined by its shape, the section modulus, moment of inertia and corresponding strength of H-shaped steel are significantly better than ordinary I-shaped steel of the same single weight. When used in metal truss structures with different requirements, it can greatly improve the load-bearing capacity and stability of the overall structure and reduce structural weight. At the same time, because the inner and outer sides of its flanges are parallel and the edge ends are at right angles, it is easy to assemble and combine into various components, which can greatly save the subsequent welding and riveting workload, thereby speeding up the construction speed of steel structure projects and shortening the construction period.

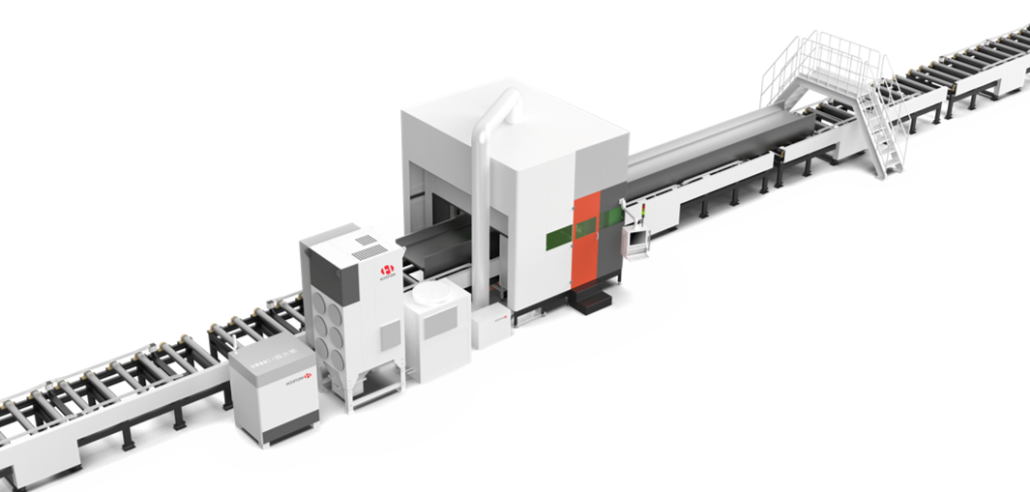

H-shaped steel laser cutting machine is an efficient and accurate automated equipment, mainly used for H-shaped steel processing in steel structure buildings. The equipment uses laser technology and is controlled by a computer to accurately cut metal sheets of various thicknesses. Its main components include laser generator, reflector, CNC workbench, cooling system, etc.

In steel structure buildings, H-shaped steel laser cutting machines are mainly used for cutting, processing and drilling of H-shaped steel. Compared with traditional mechanical processing methods, H-shaped steel laser cutting equipments have the following advantages:

- High precision: The focus point of the laser beam is very small, allowing high-precision processing.

- Fast speed: Laser processing is very fast, which can greatly improve production efficiency.

- High flexibility: The energy of the laser beam can be precisely operated under computer control and can be adapted to various shapes of metal components.

- Low cost: During laser processing, there is no need to use consumables such as cutting tools, so subsequent maintenance costs are low.

- As the proportion of steel structure buildings in the construction industry increases year by year, the market prospects for H-shaped steel laser cutting machines are very broad. In the future, with the development and technological advancement of the construction industry, H-shaped steel laser cutting machines will continue to be optimized and improved to further improve production efficiency and processing accuracy.

In short, the H-shaped steel laser cutting machine, as an efficient and accurate automation equipment, has broad application prospects in steel structure buildings. In recent years, the impact of engineering productivity efficiency and personnel and site cost control on corporate benefits has become more and more prominent. HGTECH special laser cutting machine for section steel can effectively improve work efficiency, improve product processing accuracy, reduce manual use, the area occupied by production equipment, and reduce processing costs. It also helps the company’s production process and cost control, management level, and market competitiveness.