Projects

Introduction To The Main Characteristics Of Industrial Laser Cutter

Preface

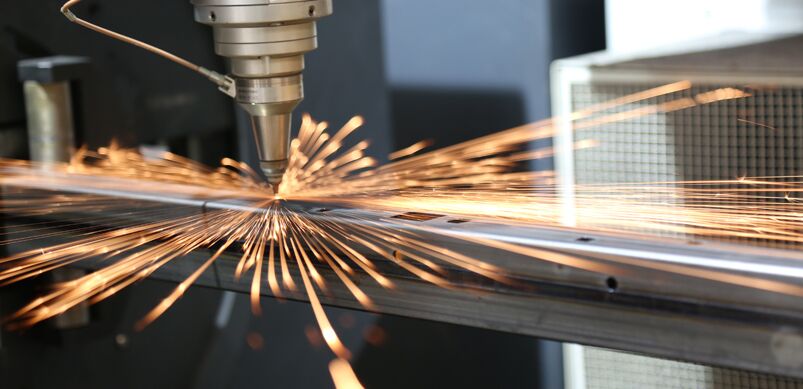

Laser cutting machines play a significant role in the industrial field, and laser cutting equipment has developed rapidly in recent years, widely used in sheet metal, hardware products, steel structures, and precision machinery industries.

The characteristics of industrial laser cutter

Firstly, industrial laser cutting machines have smaller cutting seams, resulting in less deformation of the workpiece during processing. The laser beam is focused into very small light points, achieving a high power density at the focal point. At this point, the heat input by the beam far exceeds the portion reflected, conducted, or diffused by the material, and the material quickly heats up to the point of vaporization, evaporating and forming pores. As the light beam moves linearly with the material, the holes continuously form narrow slits. The edge cutting is minimally affected by heat and there is basically no deformation of the workpiece.

Secondly, laser cutting is a non-contact processing with high energy and good density controllability. After focusing the laser beam, it forms a very small focal point with extremely strong energy, which has many characteristics when applied to cutting. Firstly, laser light energy is converted into amazing thermal energy and kept in a very small area.

The laser beam does not apply any force to the workpiece. It is a non-contact cutting tool, which means that the workpiece has no mechanical deformation, no tool wear, and there is no need to consider the conversion of the tool. The cutting material does not need to consider its hardness, and it also indicates that the laser cutting ability of industrial laser cutter is not affected by the hardness of the material being cut. Any material with any hardness can be cut.

Moreover, the laser beam has strong controllability, high adaptability and flexibility, making it convenient to combine with automation equipment and easily achieve automation of the cutting process; Due to the absence of restrictions on cutting workpieces, the laser beam has unlimited ability to perform contour cutting; Combined with computers, it can layout the entire board and save materials.

Finally, industrial laser cutting machines have a wide range of adaptability and flexibility. Compared with other conventional processing methods, laser cutting has greater adaptability. Firstly, compared to other thermal cutting methods, as a thermal cutting process, other methods cannot act on a very small area like a laser beam, resulting in a wide incision, a large heat affected zone, and significant workpiece deformation. Laser can cut non-metals while other thermal cutting methods cannot.

Summary

Compared to traditional cutting processes, industrial laser cutting equipment has the characteristics of high precision, fast cutting speed, not limited to cutting pattern limitations, automatic layout saving materials, smooth cutting, and low processing costs. The cutting process of laser cutting machines is much more advanced than traditional cutting processes, which also makes more industrial manufacturers choose laser cutting equipment when cutting plates.