Projects

Laser Cutting Technology Helps The Shipbuilding Industry

How to achieve the integration of ship intelligent manufacturing

As a symbol of a country’s industrial strength, the shipbuilding industry has extraordinary industrial expansion and strong economic driving force, and is known as the “crown jewel of comprehensive industry”. In recent years, in response to the trend of transformation and upgrading in the shipbuilding industry, HGTECH has actively entered the high-end shipbuilding field.

From laser cleaning and cutting of raw materials for ship components, to laser welding of small and medium-sized components, to planning and design of intelligent production lines for ship thin plates, as well as advanced manufacturing of core components of green energy power systems, we will accelerate the implementation of integrated solutions for laser intelligent manufacturing of ship components, and accelerate the collaborative upgrading of high-end, green, and intelligent shipbuilding technologies. In this section, we will introduce the laser cutting intelligent equipment used in the manufacturing of ship components.

Laser cutting and material processing are more efficient

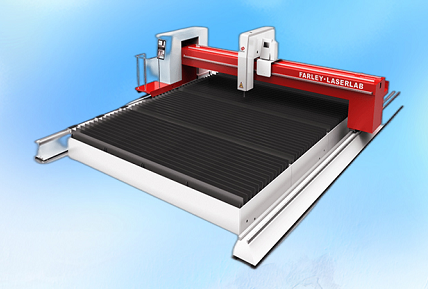

As the main raw materials for shipbuilding, the cutting efficiency and quality of ship steel plates and profiles directly affect the production and utilization of ships. A typical application scenario occurs during the material cutting process of decks, components, and parts. Shipyards need to cut the entire board into various required shapes, which requires high precision in material cutting. However, traditional cutting equipment and manual cutting operations are difficult to meet the requirements of cutting accuracy, efficiency, and quality. Laser cutting intelligent equipment has become the mainstream choice for material cutting operations due to its high accuracy, no impact on materials, and high safety factor.

The advantages of laser cutting technology in ship plate cutting are reflected in its high precision and low thermal deformation, reducing the need for secondary processing (such as edge milling, drilling, etc.), transportation, polishing, especially for the processing of small circles, small holes, and curved surfaces. Laser cutting technology endows the shipbuilding industry with efficient and high-precision metal processing, short production cycles, and lower production costs. While ensuring equipment quality, it helps to reduce installation workload, shorten installation cycle, and save material and labor costs.

Summary

Laser cutting technology brings high-efficiency and high-precision metal processing, ultra-short production cycles, and lower production costs to the shipbuilding industry. Laser cutting technology, as a non-contact, non polluting, low noise, and material saving green processing technology, has begun to show its digital, intelligent, and flexible characteristics.

With the development of laser technology. The application scope of laser processing in the shipbuilding industry is gradually expanding, and the large-scale popularization of laser cutting and welding in the shipbuilding industry is just around the corner.