With the rapid development of Industry 4.0, the demand for high-precision and high-efficiency cutting equipment in the manufacturing industry is on the rise. In the Americas, plasma cutting equipment is widely popular, but in recent years, the strength of laser cutting equipment has also been gradually recognized by a large number of users. Today, we will delve into the analysis of these two cutting technologies, providing insights to help you choose the best equipment for your factory.

Plasma Cutting

Plasma cutting technology, with its characteristics of high speed, high precision, and high adaptability, has secured its place in the manufacturing industry. Its working principle involves using high-temperature plasma arcs to cut materials, primarily suitable for cutting metal.

Advantages:

- Fast cutting speed, suitable for mass production.

- Simple operation.

Disadvantages:

- For heavy materials, the cutting effect is not as good as laser.

- Expensive equipment with a significant upfront investment.

- Generates harmful gases during operation, requiring ventilation facilities.

Laser Cutting

Laser cutting technology, utilizing high-energy, high-density laser beams as cutting tools, boasts high cutting precision and excellent cut quality. It is widely used for cutting various materials.

Advantages:

- Excellent cut quality, high precision.

- Applicable to various materials, including metals, non-metals, and composite materials.

- Easy operation, high level of automation.

- Long equipment lifespan, low maintenance costs.

Disadvantages:

- Higher equipment prices.

- Requires a cooling system, making maintenance relatively complex.

Comparing plasma and laser technologies, laser cutting machines offer several significant advantages:

1. High Precision Cutting:

Laser cutting machines use a high-energy laser beam, enabling extremely precise cuts in small areas, surpassing the precision of plasma cutting. This makes laser cutting ideal for applications that require fine, intricate cuts.

2. Versatility Across Materials:

Laser cutting technology adapts to various materials, including metals, non-metals, and composites. In contrast, plasma cutting is primarily limited to metals. The multi-material versatility of laser cutting makes it a more widely applicable choice across different industries.

3. Low Waste Generation:

Laser cutting produces minimal waste during the process, contributing to its environmental advantages compared to plasma cutting. This aligns with the increasing societal focus on sustainable development and environmentally friendly production.

4. Automation and Intelligence:

Equipped with advanced control systems, laser cutting machines achieve highly automated production processes. This enhances production efficiency, reduces the potential for human errors, and positions laser cutting machines competitively in future trends.

5. Minimal Deformation in Fine Cutting:

Laser cutting often achieves deformation-free cuts, especially in fine cutting applications. This is crucial for tasks that require high-quality, precisely shaped cuts, where plasma cutting may exhibit comparatively lower performance.

In summary, laser cutting machines, with their advantages in high precision, material versatility, low waste generation, and automation, are better suited to meet the demands of modern manufacturing for efficient, precise, and environmentally conscious production.

The Future Trend

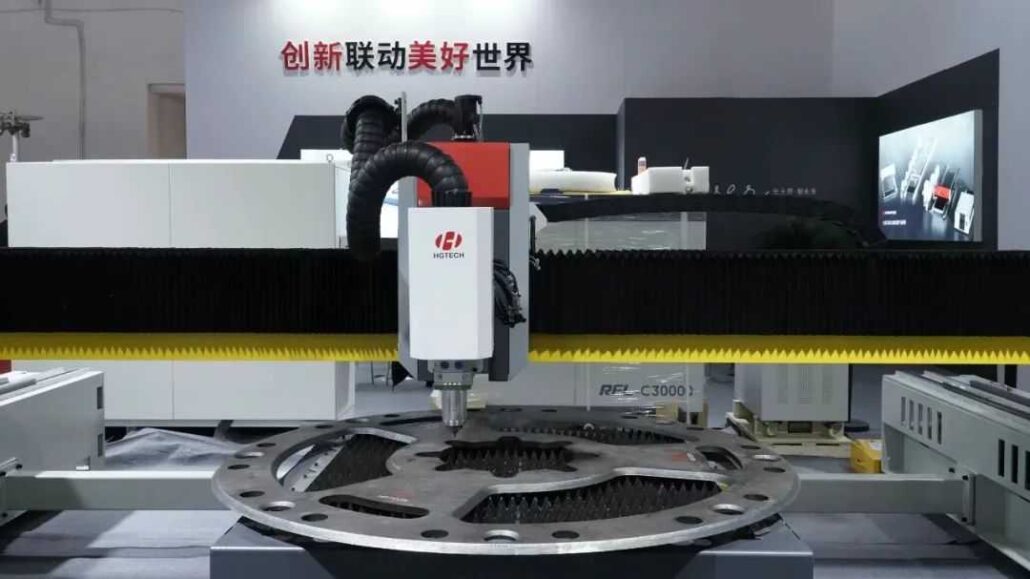

HGTECH’s Marvel fiber laser cutting machine, with optional middle and high power, utilizes a Raycus laser source for efficient cutting. The double-driven gantry structure, aerospace-grade crossbeam, and patented hollow bed ensure stability. It guarantees high precision with linear guide rails and efficient transmission. Marvel excels in cutting stability, offering top-notch quality and cost-effective performance. The Farley A2300 control system enhances productivity with automatic features. With a focus on customer support, Marvel also features a remote diagnostic system and worldwide service outlets for timely responses.

- High efficiency: maximum 320% increase in cutting efficiency; maximum X,Y positioning speed of 169m/min, maximum acceleration of 3G.

- New technology: high speed perforation flying cut, expert cutting process database accumulated by 20 years of experience.

- Intellectualization: optional visual positioning, automatic nozzle change, hydraulic lifting table, sheet metal automation and three-dimensional material storage.

- Excellent system: equipped with new upgraded FARLEY A+ 2300 operating system; self-developed special cutting HMI software interface, convenient operation, self-contained production information statistics, high openness of the system, can be extended to achieve customized MES interface.

HGTECH WALC large-format high-power laser beveling equipment adopts high power continuous fiber laser, with high precision five-axis linkage self-developed CNC system and self-developed programming software, solving the problem of high precision beveling in one time, which is widely used in bridge/ship/special vehicle manufacturing/construction machinery/steel structure and other machinery manufacturing and infrastructure fields.

- Unique core algorithm control: self-developed CNC system can realize gradient bevel and other complex bevel (such as heavenly circle bevel) cutting on material, realizing real five-axis linkage

- Automatic nesting and G-code generation: self-developed nesting software can nest the parts that customers need to process and convert the gen files generated by tribon/ AM/ CATIA into cutting machine G-code, saving a lot of manpower time

- Super large format: Double-drive gantry compensation technology (patented) with a maximum effective cutting width of 6 meters and beveling device with chord length adjustment function to ensure the best product accuracy

- Flexible production line integration: can be docked with the customer’s intelligent factory MES/PDAC and other servers, saving labor and improving efficiency

- Wide range: can process carbon steel/stainless steel/aluminum plate/nonferrous metal, etc.

- Super capacity: plate cutting thickness up to 100mm