Projects

The Application Prospects of Laser Quenching Technology in the Automotive Industry

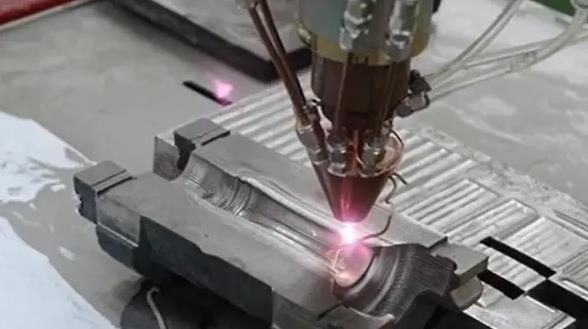

Laser quenching technology has broad application prospects in the automotive industry, providing higher hardness, wear resistance, and corrosion resistance for automotive components, thereby improving the performance, reliability, and safety of automobiles. The following will discuss in detail the application prospects of laser quenching technology in the automotive industry.

1. Handling of engine components.

The engine is one of the core components of automobiles, and its components withstand extreme working conditions of high temperature, high pressure, and high friction. By laser quenching engine components such as crankshafts, connecting rods, cylinder liners, etc., their hardness and wear resistance can be improved, their load-bearing capacity can be enhanced, wear and friction can be reduced, the service life of the components can be extended, and the efficiency and reliability of the engine can be improved.

2. Handling of transmission components.

The transmission is an important component of the automotive transmission system, and its components are often subjected to high-speed and high load working conditions. Using laser quenching to treat transmission gears, shafts and other components can significantly improve their wear resistance and strength, reduce tooth surface wear and deformation, improve transmission efficiency and smoothness, and extend the service life of the transmission.

3. Handling of brake system components.

The braking system is an important guarantee of automotive safety, and its key components such as brake discs and brake drums need to have good wear and corrosion resistance. By laser quenching the friction surfaces of brake discs and brake drums, their hardness and wear resistance can be greatly improved, the risk of brake failure can be reduced, and braking efficiency and driving safety can be improved.

4. Handling of automotive body components.

Body components such as car doors, body frames, etc. need to have high strength, stiffness, and corrosion resistance. By laser quenching body parts, their hardness and corrosion resistance can be improved, the rigidity and durability of the body can be enhanced, and the safety and structural stability of the entire vehicle can be improved.

In summary, laser quenching technology has broad application prospects in the automotive industry. By improving the hardness, wear resistance, and corrosion resistance of automotive components, laser quenching technology can significantly improve the performance, reliability, and safety of automobiles, meeting consumers’ demand for high-quality and highly reliable automotive products. With the continuous development and maturity of laser technology, it is believed that laser quenching technology will be widely applied in the automotive industry and bring new technological breakthroughs and development opportunities to the automotive industry.