Projects

Application of Laser Processing Technology in the New Energy Vehicle Manufacturing Industry

Car manufacturers are facing fierce competition, and they must find ways to cut costs, especially in battery manufacturing. This means that the production line must become faster and more efficient. Assuming that manufacturers have exhausted all the potential of production line automation, there is only one way to achieve these two goals – by deploying more powerful lasers, having stronger beam shaping capabilities, more complex sensors, and ultra precise dynamic welding processing heads. Of course, this also requires a lot of process knowledge.

In electric vehicles, the cost of battery systems accounts for nearly 50% of the total vehicle cost. The processing quality during the manufacturing process determines the battery’s storage capacity and service life. Shangtuo’s laser processing technology can improve welding quality and production efficiency, reduce welding spatter, improve the reliability, consistency, and yield of battery manufacturing, and enhance the endurance of electric vehicles. Laser welding technology is becoming a key technology in the production and processing of new energy vehicles and their parts. It is known as “the brightest light, the fastest knife, and the most accurate ruler”. It has outstanding advantages in reliability, accuracy, and efficiency.

Taking the current mainstream flat wire drive motor as an example, the laser technology involved includes welding of motor silicon steel sheets, repainting and welding of hairpin flat wires, and welding of motor busbars. The high repeatability and reliability of lasers can ensure that motors always achieve excellent conductivity in mass production. For example, in the paint removal process of flat copper wire, pulse laser ablation is a very economical and reliable process solution. Compared with mechanical processes such as planing and milling, the paint removal efficiency of laser processing can be improved by more than 80%.

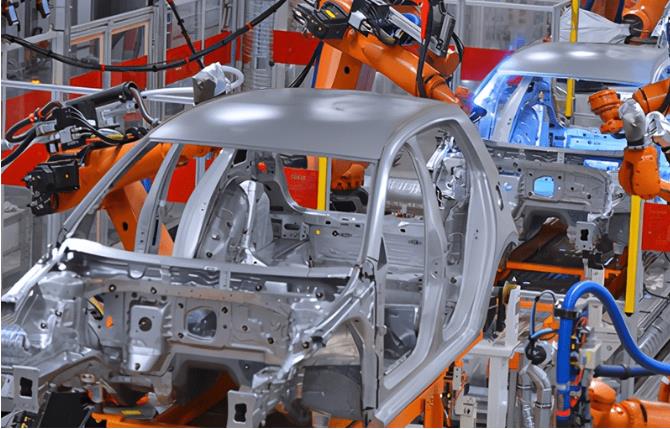

In the field of car body, laser welding has long been famous. Now, many advantages, such as flexibility, automation and low production costs, have expanded the application of laser. From assembly, body in white, to the production workshops of car parts such as seat upholstery, laser applications can be seen almost everywhere. Regardless of whether it is a new energy vehicle or a traditional fuel vehicle, taking the hot formed parts of the vehicle body that can meet both strength and weight reduction/thinning requirements as an example, the mainstream choice for both main engine manufacturers and component manufacturers is 3D laser cutting.