Projects

Laser Welding Enhances The Lightweight Of Automobiles

Cars have become a necessity in daily life, and the safety, performance, and appearance of cars are several aspects that users are most concerned about. In order to pursue the lightweight and safety of cars, automobile manufacturers often use laser welded hot formed high-strength steel in their manufacturing.

Advantages of Hot Formed High Strength Steel

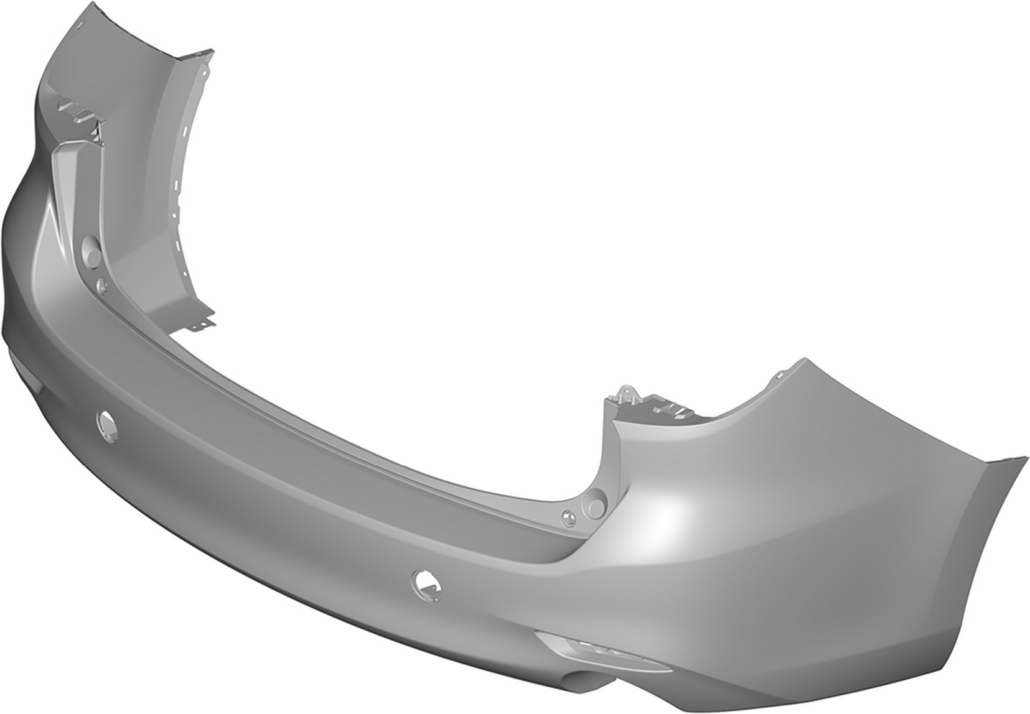

The advantage of hot-formed high-strength steel is that it has ultra-high strength, which can improve the safety of the vehicle body and improve stamping formability. It is generally used in key parts of the vehicle body, such as car door crash panels. Front and rear bumpers, A/B pillars, central aisle, upper and lower fire panels, etc. These hot-formed steel wrap the cockpit into a sturdy cage shape, which prevents the body from deforming in the event of a collision and better protects the safety of passengers inside the vehicle. Generally, the more advanced cars are, the more laser welded hot formed steel is used, and the corresponding body becomes stronger.

The advantage of hot-formed high-strength steel is that it has ultra-high strength, which can improve the safety of the vehicle body and improve stamping formability. It is generally used in key parts of the vehicle body, such as car door crash panels. Front and rear bumpers, A/B pillars, central aisle, upper and lower fire panels, etc. These hot-formed steel wrap the cockpit into a sturdy cage shape, which prevents the body from deforming in the event of a collision and better protects the safety of passengers inside the vehicle. Generally, the more advanced cars are, the more laser welded hot formed steel is used, and the corresponding body becomes stronger.

Welding difficulties of hot formed high-strength steel

After a series of hot forming treatments, high-strength steel increases its strength, which is a challenge for the cutting process. Moreover, the surface of the hot formed high-strength steel has an aluminum silicon coating, which improves the corrosion resistance of the components. However, for ordinary welding processes, the conductivity of the aluminum silicon coating is extremely poor. However, the traditional welding principle of resistance welding is to melt the welding position of the welded parts, Permanently bond atoms together. To solve these problems, laser welding technology can be used to improve welding performance and ensure the key to welding quality.

After a series of hot forming treatments, high-strength steel increases its strength, which is a challenge for the cutting process. Moreover, the surface of the hot formed high-strength steel has an aluminum silicon coating, which improves the corrosion resistance of the components. However, for ordinary welding processes, the conductivity of the aluminum silicon coating is extremely poor. However, the traditional welding principle of resistance welding is to melt the welding position of the welded parts, Permanently bond atoms together. To solve these problems, laser welding technology can be used to improve welding performance and ensure the key to welding quality.

Use laser welding to improve the assembly accuracy and stiffness of the vehicle body

There are hundreds or thousands of parts in a car’s body and chassis, and how to connect them together has a direct impact on the rigidity of the entire vehicle body. Laser welding can almost connect all metal materials of different thicknesses, grades, types, and grades together. Laser welding greatly improves the connection accuracy and assembly accuracy of the body, increasing the body stiffness by more than 30%, thereby improving the safety of the body.

There are hundreds or thousands of parts in a car’s body and chassis, and how to connect them together has a direct impact on the rigidity of the entire vehicle body. Laser welding can almost connect all metal materials of different thicknesses, grades, types, and grades together. Laser welding greatly improves the connection accuracy and assembly accuracy of the body, increasing the body stiffness by more than 30%, thereby improving the safety of the body.

Laser welding enhances the lightweight of automobiles

The use of laser welding can replace cast parts with more stamped parts in automobile manufacturing, and continuous laser welding can replace scattered spot welds, reducing the overlap width and some strengthening components, reducing the volume of the body structure itself, thereby reducing the weight of the body and meeting the requirements of energy conservation and emission reduction in automobiles.

The use of laser welding can replace cast parts with more stamped parts in automobile manufacturing, and continuous laser welding can replace scattered spot welds, reducing the overlap width and some strengthening components, reducing the volume of the body structure itself, thereby reducing the weight of the body and meeting the requirements of energy conservation and emission reduction in automobiles.