Projects

Laser Welding Of Car Bumpers

Because the bumper of a car is mainly composed of three parts: the outer panel, cushioning material, and crossbeam, the welding of the car bumper is particularly important. The automotive manufacturing industry has a wide range of welding technologies, such as laser welding, MAG, resistance welding, MIGTIGCO, and so on. However, due to the different thicknesses of the plates, the bonding technology is relatively difficult, and it is usually easier to use laser welding technology. Therefore, specialized laser welding of car bumpers is often used on car bumpers.

Introduction to Automotive Bumpers

1. The bumper is a safety device that has functions such as safety protection, vehicle decoration, and improving the aerodynamic characteristics of the vehicle.

2. The car bumper is located in most areas of the front and rear of the car.

3. The outer plate and buffer material of the bumper are made of plastic, and the crossbeam is stamped with a cold-rolled sheet with a thickness of about 1.5mm to form a U-shaped groove. The outer plate and buffer material are welded to the crossbeam, and the crossbeam is connected to the longitudinal beam of the frame with screws, which can be removed.

The function of car bumpers

1. The car bumper can absorb and slow down external impacts, protecting the front and rear of the vehicle body. It can avoid the impact of external damage to the car’s safety system.

2. The car bumper can play a buffering role in the event of a low-speed collision, protecting the front and rear vehicle bodies.

3. Car bumpers have the ability to reduce injuries to drivers and passengers during high-speed collisions, and can play a certain role in protecting pedestrians in accidents.

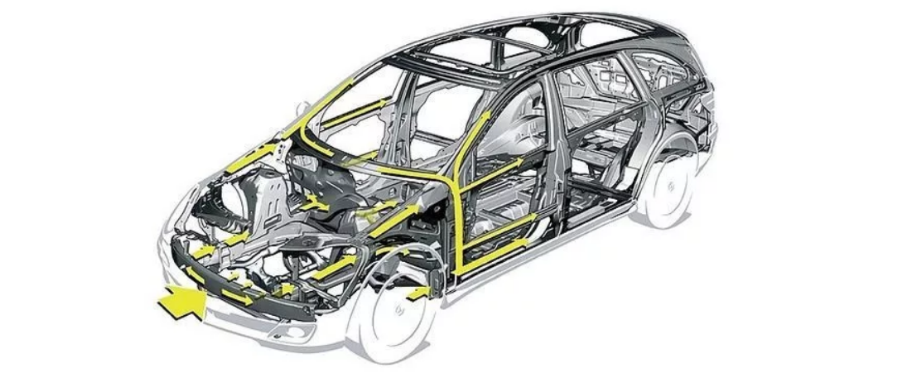

When the vehicle or driver is subjected to collision force, they first come into contact with the bumper, which then disperses the force to the energy absorption boxes on both sides and transmits it to the left and right front longitudinal beams, and then to other structures of the vehicle body. It absorbs and alleviates external impacts, dispersing collision forces. Generate buffer devices to protect people and vehicles.

5. The appearance is decorative and has become an important component for decorating the exterior of a sedan. It pursues harmony and unity with the body shape, and the welding of the car bumper pursues its own lightweight.

Summary

Under the “dual carbon” goal, the automotive industry is facing new directions and opportunities. Electrification, networking, and intelligence have become the necessary paths for the future development of the automotive industry. The traditional automotive component system is also facing structural transformation and industrial upgrading, and laser welding is still the best choice for the automotive industry.