Uncategorized

Online Laser Marking for Food Packaging: Innovation and Future

As consumer demands for food safety and quality continue to rise, the food packaging industry faces stricter regulations and market requirements. Traditional packaging marking technologies, such as hot stamping and ink printing, have gradually exposed some issues, such as wearability, pollution, and unclear printing. Especially in the food sector, the information on packaging needs to be not only clear and visible but also protected from external environmental factors. These traditional methods often fail to meet the high standards of today’s market. Additionally, with the increasing environmental requirements in the food industry, the chemicals and materials used in traditional printing methods have raised more concerns. In this context, online laser marking for food packaging, as an efficient, environmentally friendly, and precise alternative, is increasingly gaining favor in the industry.

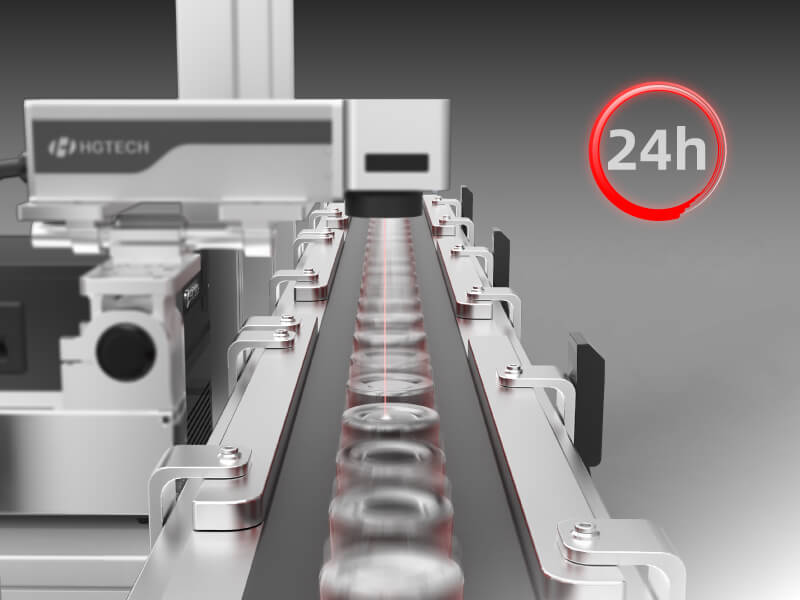

Laser marking technology, with its unique advantages, is gradually replacing traditional printing techniques in the food packaging industry. Unlike conventional marking methods, laser marking uses a high-energy laser beam to etch packaging materials without the need for ink or chemicals, thus avoiding the pollution of the environment and the potential health risks to consumers. Laser marking not only ensures that the graphic and text information on food packaging is clear, durable, and resistant to wear but also offers high precision, effectively preventing the common problems of blur or unevenness often seen in traditional printing methods. Whether it’s paper packaging, plastic bottles, glass bottles, or metal cans, laser marking can achieve stable and precise marking on various materials. Moreover, laser marking is fast and can easily adapt to high-speed production lines, ensuring that there are no bottlenecks in large-scale production. For manufacturers, laser marking not only improves production efficiency but also reduces material waste, further lowering costs. It is worth mentioning that laser marking is highly flexible, capable of handling packaging items of different sizes and shapes, making it highly adaptable. Additionally, it supports more diverse design content, such as QR codes, barcodes, and microtext, which meets consumers’ demands for food traceability. Therefore, laser marking technology not only enhances the quality of food packaging but also meets the modern market’s multifaceted requirements for packaging safety, environmental friendliness, and transparency of information, making it a significant technological innovation in the food packaging industry.

Looking ahead, online laser marking for food packaging will become more widely used as technology advances and equipment costs continue to decrease. With the growing importance of environmental protection and traceability technologies, laser marking will become a driving force in the development of the food packaging industry, pushing the sector toward more efficient and sustainable directions.

About HGTECH

HGTECH is the pioneer and leader of laser industrial application in China, and the authoritative provider of global laser processing solutions. We comprehensively layout the construction of laser intelligent equipment, measurement and automation production lines, and smart factories to provide an overall solution for intelligent manufacturing.

We deeply grasp the development trend of manufacturing industry, constantly enrich products and solutions, adhere to exploring the integration of automation, informatization, intelligence and manufacturing industry, and provide various industries with laser cutting systems, laser welding systems, laser marking series, laser texturing complete equipment, laser heat treatment systems, laser drilling machines, lasers and various supporting devices The overall plan for the construction of special laser processing equipment and plasma cutting equipment, as well as automatic production lines and smart factories.