Laser marking can be understood as the process of using a laser beam to create permanent marks on different surfaces. Various types of lasers are employed for different materials. The advantages of laser marking equipment lie in its ability to produce marks without consumables, generate minimal pollution, achieve high processing efficiency, precision, and irreversible processing, ensuring that the marks cannot be tampered with later. This is beneficial for product quality traceability, ultimately enhancing product competitiveness. As technology advances, laser marking is expanding into more diverse application scenarios, with some applications replacing traditional mechanical marking processes.

It seems that laser technology is somewhat distant from our daily lives. However, in our everyday lives, we can actually see the presence of laser processing in many places. For example, when going shopping, the barcodes we see, as well as many accessories on clothing, are often produced through laser processing. Besides, CD/DVD also cannot do without this technology.

Food Industry

When consumers purchase puffed food, inadequate sealing of the packaging bag can lead to spillage of the contents and a shortened shelf life within the expiration date. Furthermore, if the seal is too tight, it can be difficult to tear along the dotted line, making it challenging to open certain food packages with control. From a consumer’s perspective, all of these issues can be quite frustrating. But a laser marking machine can selectively mark a single thin film layer within flexible packaging. This enables perfect and easy tearing of the flexible packaging while maintaining the integrity of the film, ensuring that the outer film remains intact and undamaged. As a result, we can effectively prevent issues such as exposure to light and moisture inside the packaging.

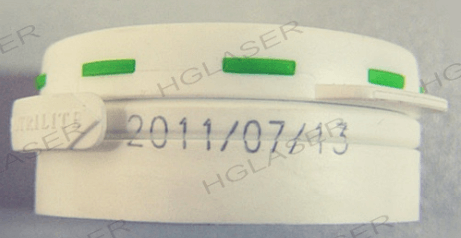

Package Laser marking machines are also utilized for marking information on beverage packaging bottles and boxes, including brand logos, anti-counterfeit codes, production dates, batch numbers, shelf life, regulatory barcodes, QR codes, and more. Employing non-contact laser processing, laser marking machines address various drawbacks of traditional methods. The anti-counterfeit performance of laser-marked codes is superior, effectively combating counterfeit products. The barcode information marked by lasers is clear, resistant to high temperatures and corrosion, and difficult to erase. Through QR code traceability systems, full traceability can be achieved, enhancing supervision over distribution and agency across different regions effectively.

Pharmaceutical Industry

The pharmaceutical industry operates under extremely stringent scrutiny standards, from verifying the drugs to rigorous control over the entire production process. This commitment to industry fundamentals determines the long-term survival of every pharmaceutical company. No need to say the quality of the drugs, strict control is also required for aspects such as packaging and coding during the production process alone.

With the introduction of laser marking machines, they have gained favor among pharmaceutical and capsule manufacturing enterprises. Some renowned pharmaceutical companies have already adopted capsule laser marking machines for their soft capsule production.

Paper box packaging for pharmaceuticals can undergo direct tri-stage marking using CO2 laser marking machines, completely replacing inkjet printers. Laser marking provides permanent marks, which can effectively combat counterfeit products, further ensuring that people can use genuine and regulated medications for their health.

For some bottled medications, some products opt for laser marking inside the bottle caps to enhance anti-counterfeiting quality, effectively ensuring the legitimacy of pharmaceutical distribution channels.

Aluminum foil boards and plastic boards are also typically marked by laser technology, enabling precise positioning without compromising the quality of the medication itself.

Rigid Plastics

Polyethylene (PE) and high-density polyethylene (HDPE) are among the most common plastics used for rigid packaging. Due to their relatively low surface energy, marking on plastic containers can pose challenges. To enhance product quality, extend shelf life, and meet consumer demands, advanced equipment like laser marking machines is widely used in the plastic packaging industry.

HGTECH offers a range of solutions for the packaging industry:

The series machines can mark permanent makers, work in adverse conditions and meet the demands of all kinds of packing materials.

● Flexible structure, fast speed, high security;

● High efficiency, high electro-optic conversion efficiency;

● Long life, easy operation, low running cost, operated in 24 hours.

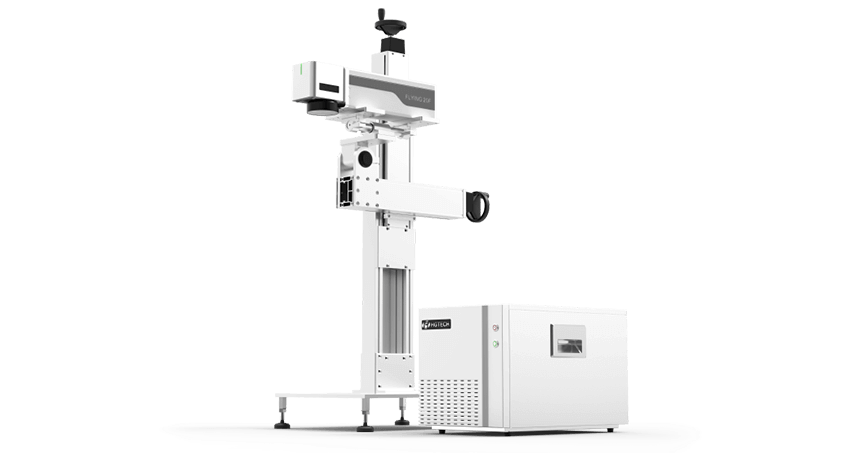

Flying Fiber Laser Marking

It’s widely used in packaging industry

● Small structure, the professional bracket can be installed on the assembly line, easy adjustment;

● Professional industrial laser source, fast marking speed, high reliability, operated continuously in 24 hours, meet the demands of mass processing and production;

● High electro-optic conversion efficiency, low consumption, long life, save costs for customers;

● Friendly man-machine dialogue interface, easy operation, without bothering for the operators altering.