Projects

How Domestic Laser Weakening Stands Out, HGLaser Has the Answer

There is an explosion that can protecting your safety to the fullest — that’s the airbag, the “guardian angel” of life.

In the early days, cars used separate embedded airbags, which had obvious color differences and significantly disrupted the overall aesthetic of the dashboard. With technological upgrades in the automotive industry, from luxury cars worth millions to budget-friendly models costing just a few thousand, the integration of invisible passenger-side airbags into the dashboard has become mainstream.

Laser weakening, as a modern precision machining method, differs from traditional methods like CNC milling ablation, cold blade, and hot blade ablation. It is a non-contact, non-cutting force process with minimal thermal impact. This method is applicable to the vast majority of materials commonly used today, such as molded plastic leather materials like TPO and PU, as well as vacuum-formed surface materials like PVC and ABS.

Laser weakening machine can process both homogenous materials such as PP injection-molded dashboard bodies and complex structures consisting of frameworks, foam layers, and cross-linked skins. Therefore, laser weakening technology has a wide range of material applications and clear advantages.

Laser weakening technology utilizes the high energy of lasers by focusing the laser beam within a range of approximately 0.2 mm, achieving power densities as high as 108 to 1010 W/cm², or even higher. By applying frequency-controlled pulses to the dashboard, the material at the focal point rapidly vaporizes upon absorbing the high-energy laser, forming small holes that penetrate or do not penetrate (as needed). These areas of small holes result in thinner material thickness and reduced fracture strength, allowing them to preferentially fracture when subjected to external impacts.

Due to the lack of core technologies such as residual thickness full closed-loop control systems, in the past, laser weakening equipment for airbag lines was monopolized by foreign producers. Customers in the Chinese automobile industry have been deeply troubled by its high prices, long supply cycles, delayed after-sales service, high costs, and high prices of supporting fixtures.

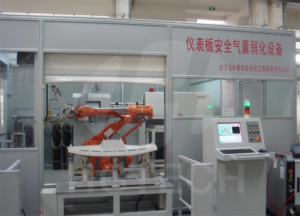

In 2008, HGLaser, as the leading role in the field of laser technology, formed a “iron triangle team” with Huazhong University of Science and Technology and a well-known domestic automobile company. They successfully developed a laser weakening technology and equipment for automobile instrument panel airbags with complete independent intellectual property rights, suitable for the production of multiple varieties. This technology met the manufacturing needs of the automobile industry for high precision, stability, flexibility, and aesthetics, making them one of the only two companies globally capable of providing laser weakening technology and equipment.

The launch of the first domestically-produced laser weakening equipment filled a technological gap in the domestic field and broke the industry monopoly of foreign companies, forcing them to lower their import prices by over 20%. It significantly propelled the development of China’s automobile manufacturing industry.

Currently, the first HGLaser laser weakening equipment has been operating smoothly for 13 years, gradually entering mass production and expanding market share. Through its performance, it has demonstrated that domestically-produced equipment can match the processing accuracy, reliability, and stability of imported equipment.

The airbag in a car is only deployed once throughout its entire lifecycle, but it’s this single deployment that determines the life or death of the occupants. Therefore, the production process of airbags must ensure safety and precision to meet design requirements during its one-time deployment.

01 Traceability

According to relevant national laws and regulations, the production data of each airbag must be preserved for a traceability period of 15 years.

HGLaser’s fifth-generation JRC series airbag laser weakening equipment is equipped with a self-developed closed-loop control system. By setting a series of quality inspection points, the production process is accurately recorded, calculated, and stored in a database to ensure that defective components are not selected. It achieves 100% traceability of product process data, providing “escort” for safe driving.

02 High Safety

When the airbag deploys, it exerts instant enormous forcee, pushing the airbag cover plate along the airbag line to open. Therefore, residual thickness accuracy of the airbag weakening line plays a crucial role in protecting life safety. If the residual thickness is too thin, it may leave traces on the dashboard, fail to achieve an invisible effect, and affect the lifespan of the dashboard. If the residual thickness is too thick, it will affect the bursting effect, unable to eject to protect people’s lives timely according to the predetermined trajectory.

HGLaser’s fifth-generation automobile dashboard laser weakening equipment features a core component — the autonomously developed residual thickness sensor closed-loop control system, ensuring the entire weakening process is highly precise and fully controllable. The point-like residual thickness can be uniformly controlled within an accuracy of 0.15±0.05mm, significantly enhancing the safety factor during deployment, turning the airbag into a life “amulet”.

03 Low Cost

Compared to imported products, domestically-produced laser weakening equipment not only matches them in performance but also offers a more reasonable price. Currently, the price of imported equipment is almost 2-3 times higher than domestically-produced ones, with expensive after-sales service costs.

With years of experience, HGLaser has accumulated numerous mature application cases, enabling us to provide customized design solutions and localized after-sales services for our customers.

As national regulations concerning safety products increase annually, coupled with the rapid growth of the Chinese automobile market, safety airbags are poised to become standard equipment for various vehicle models. The inevitable trend in the future development lies in their intelligence and multi-functionality. Consequently, airbag in China will face tremendous market demand.

In the future, HGLaser will closely follow the trends of the times, continuously optimizing and upgrading laser weakening equipment for airbags. We will continue to intensify our research and development efforts in core technologies such as control systems, thereby empowering the automobile industry to sail towards greater success.