Projects

Scanning Cutting: Exploring the New Potential of Laser Cutting Technology

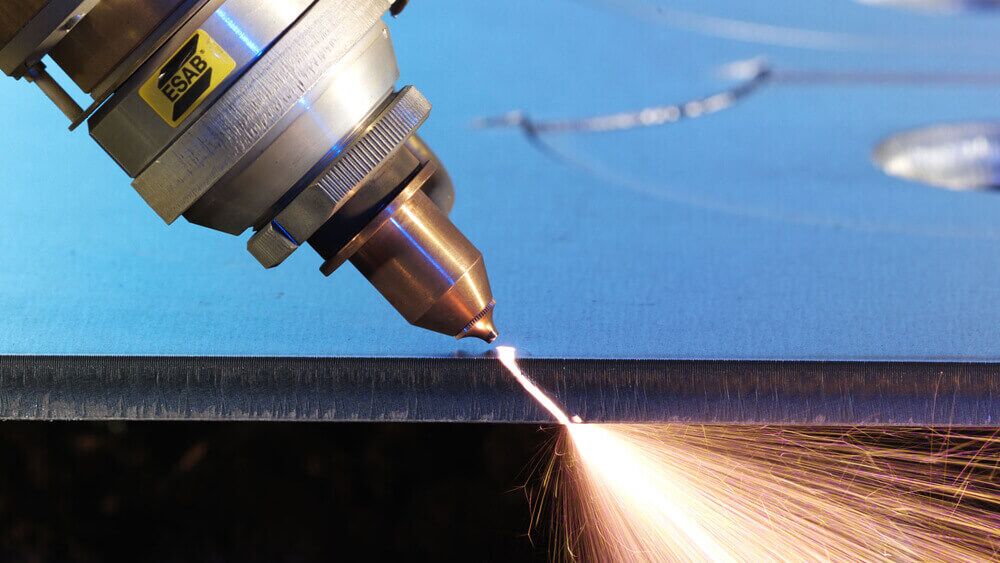

Laser cutting, as an advanced processing technology, has been widely developed and applied in the past few decades. With the continuous evolution of laser cutting capabilities and energy efficiency in the market, the demand for achieving higher efficiency at lower costs is increasing.

The traditional cutting method poses a risk of damage to the cutting head and laser when dealing with high reflective materials such as copper and aluminum, and the laser absorption rate is low and the cutting efficiency is not high. Therefore, there is an urgent need for new laser cutting processes to address these issues.

Scanning cutting can dynamically control the movement of laser focused light spots. Different material thicknesses are used to adjust the swing shape and amplitude of the light spots, making the laser energy accumulation mode more conducive to cutting according to the distribution of cutting requirements. Scanning cutting has the following advantages:

Cutting thickness reaches new limits

Scanning cutting has achieved better performance of the machine, greatly improving the cutting thickness for traditional materials, exceeding the limit of traditional thickness.

Significant improvement in speed

After practical testing, compared to traditional cutting, the average cutting speed of scanning cutting has increased by more than 50%, which is conducive to shortening the production cycle, improving production capacity, and achieving significant breakthroughs in laser cutting efficiency.

Solve laser direct return

The oscillation of the scanning cutting spot reduces reflectivity, increases energy absorption, and effectively solves the problem of laser direct return of high reflection materials, achieving effective cutting of high reflection materials such as copper and aluminum.

Laser cutting technology has significant advantages in accuracy, speed, flexibility, and automation, providing efficient and accurate solutions for manufacturing and processing in various industries. Scanning cutting, as a new milestone in laser application technology, has achieved higher efficiency and more functionality for laser cutting, bringing huge improvements and improvements.