Projects

The Potential Of 3D Laser Cutting Is Increasing Day By Day

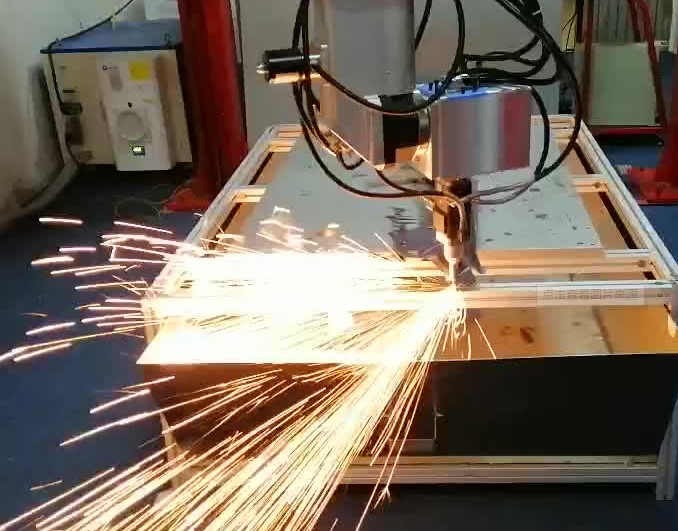

The 3D five axis laser cutting machine is a laser processing equipment for cutting 3D parts with complex curved surfaces. It is mainly used to solve the problem of cutting holes and trimming edges on 3D irregular surfaces, and is used to replace punching and trimming dies. The three-dimensional five axis laser cutting machine has the advantages of high accuracy, fast speed, good dynamic performance, good cutting effect, and high production efficiency. It is increasingly widely used in fields such as automobiles, electronics, molds, household appliances, military industry, and aviation.

The 3D five axis laser cutting machine belongs to high-end machine tool equipment, and the industry has high talent, funding, and research and development barriers. Due to this limitation, the early global 3D five axis laser cutting machine market was mainly monopolized by companies such as Germany and Italy. Later, with technological progress, Japan and China also joined this market. With technological progress, the market layout of 3D five axis laser cutting machines continues to increase, and market competition is intensifying. In the international market, suppliers of 3D five axis laser cutting machines include German Trumpf Group, Italian Prima, Japanese Komatsu, BLM Group, and others.

According to the “2022-2026 China 3D and Five Axis Laser Cutting Machine Industry Market Monitoring and Future Development Prospects Research Report” released by the New Thinking Industry Research Center, China is the fourth country in the world to independently master 3D and five axis laser processing technology, and the growth rate of the 3D and five axis laser processing equipment market is higher than the global average. It is expected that from 2021-2027, The market for three-dimensional and five axis laser processing equipment in China will grow from $70 million to $140 million.

At present, two-dimensional sheet metal cutting is still the mainstream process in the market, but with the increasing complexity of processed parts, two-dimensional sheet metal cutting has encountered bottlenecks in technology, accuracy, efficiency, and other aspects. The three-dimensional and five axis laser processing technology is becoming increasingly mature. With the upgrading of demand, the application of three-dimensional and five axis laser processing technology is expanding, and the market development space for three-dimensional and five axis laser cutting machines is broad.

Overall, China’s 3D five axis laser cutting machine enterprises started late, and their core technology and component requirements still rely on imports. The localization rate of 3D five axis laser cutting machines is still relatively low. At present, domestic 3D and 5-axis laser cutting machine enterprises include HGLASER, Han’s Laser, Pentium Laser, and others.

From the perspective of development trends, the application field of 3D five axis laser cutting machines is increasingly expanding, and downstream demand is showing a diversified development trend. To meet the multi-dimensional market demand, 3D five axis laser cutting machines are gradually upgrading towards intelligence, automation, lightweight, high efficiency, and low energy consumption.

Industry analysts from Xinsijie stated that as high-end processing equipment, 3D five axis laser cutting machines have advantages such as high precision, high efficiency, and fast speed. With the upgrading trend of the manufacturing industry, the market demand for 3D five axis laser cutting machines will continue to be released, and the future development prospects of the industry are promising. The number of 3D five axis laser cutting machine enterprises is constantly increasing, and market competition is intensifying. With the active research and development of relevant enterprises, 3D five axis laser cutting machines will be upgraded towards intelligence, lightweight, and low energy consumption.