Projects

The Principle and Efficiency of Laser Cleaning of Seal Molds

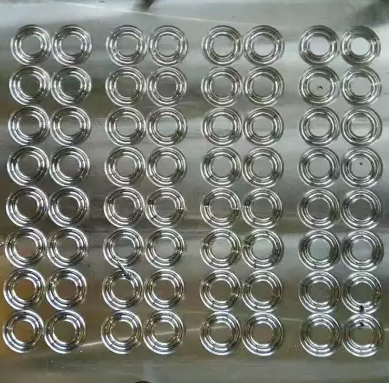

Laser cleaning of seal molds has good results and high efficiency, and can be done by hand or automated cleaning.

With the continuous development of industrial technology, the methods of cleaning seal molds are also constantly updated and improved. In traditional cleaning methods, using chemicals and mechanical equipment to clean is time-consuming and labor-intensive, and poses a significant threat to the environment and human health. However, there is now a new cleaning technology – laser cleaning, which can clean seal molds faster and more effectively without generating chemical pollutants, making it more environmentally friendly and safe.

Diversity of laser cleaning

Laser cleaning is a cleaning solution that uses high-frequency short pulse laser as the working medium. The high-energy laser beam of a specific wavelength is absorbed by the rust layer, paint layer, and pollution layer, forming a rapidly expanding plasma (highly ionized unstable gas), while generating shock waves that cause pollutants to become fragments and be removed. Mainly used on metal or non-metallic surfaces, it can be used for rust removal, oil removal, paint removal, coating removal, oxide layer removal, etc.

Adaptability of laser cleaning

Laser cleaning is a versatile cleaning equipment suitable for various materials such as steel, aluminum, copper, carbon steel, non-ferrous metals, ceramics, glass, etc. It is an ideal choice for the new generation of industrial cleaning technology.

There are various cleaning methods for industrial equipment at present, but most of them use chemical agents and mechanical methods for cleaning. Of course, these two methods also have varying degrees of drawbacks. Especially when the entire society places great emphasis on environmental protection, the use of chemical cleaning will inevitably generate a large amount of pollution. The cost of using mechanical methods is too high, so it is necessary to use laser cleaning at this time. What are the advantages of this equipment?

Green and environmentally friendly cleaning methods

Firstly, laser cleaning has the characteristics of non grinding and non-contact, which can not only clean metal workpieces, but also non-metal workpieces. It is also a green and environmentally friendly cleaning method, and the entire process does not require the use of cleaning fluids or any chemical agents, which will not cause pollution to the environment.

Laser cleaning technology is a cleaning method that uses the high intensity energy generated by a laser beam to remove impurities and dirt on the surface of a sealed mold. The laser beam instantly strikes surface impurities, causing them to expand and vaporize, thereby removing surface dirt and attachments. Compared to traditional cleaning methods, laser cleaning does not require the use of any chemicals or mechanical equipment, nor does it generate secondary pollution.

Secondly, the speed of laser cleaning of seal molds is very fast, and a large amount of cleaning work can be completed in a short period of time. During the cleaning process, the laser beam can quickly scan the surface of the mold, and the depth of cleaning can also be adjusted by controlling the laser energy. Therefore, laser cleaning can quickly and thoroughly clean seal molds without affecting mold quality, greatly improving production efficiency.

Integrating with automation platforms to achieve remote operation

The traditional cleaning methods are basically contact based, and excessive cleaning can cause varying degrees of damage to the surface of the object. The use of laser cleaning can not only avoid the occurrence of the above situations, but also achieve remote operation when combined with automation platforms. For cleaning some dead corners or areas that are difficult to clean, remote operation can be carried out, thus effectively ensuring the personal safety of operators.

In addition to speed and cleaning principle, laser cleaning has other advantages. For example, laser cleaning can be carried out without damaging the surface of the sealing component mold, avoiding scratches and damage that mechanical equipment may cause on the mold surface. In addition, since laser cleaning does not require the use of any chemicals, it can significantly reduce cleaning costs, thereby saving the operating expenses of the enterprise.

In summary, laser cleaning technology is an efficient, environmentally friendly, and safe method for cleaning seal molds. I believe that with the continuous development of this technology, laser technology will play an increasingly important role in cleaning seal molds.

About HGSTAR: HGSTAR is is a sub-brand of HGTECH.HGTECH the pioneer and leader of laser industrial application in China, and the authoritative provider of global laser processing solutions. We have comprehensively arranged laser intelligent machine, measurement and automation production lines, and smart factory construction to provide overall solutions for intelligent manufacturing.