Projects

Application of Laser Pipe Cutting Machine in Petroleum Screen Pipes

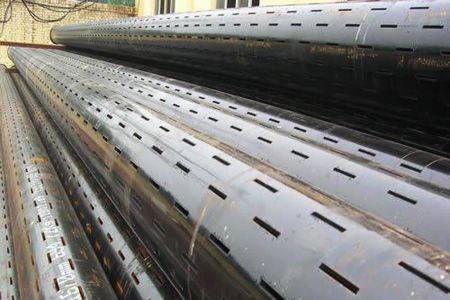

CNC laser pipe cutting machine is a specialized equipment for cutting and processing oil screen pipes. Screen pipe, also known as slotted screen pipe, is a special type of pipe installed at the bottom of seamless or welded steel well pipes in oil wells, water wells, geothermal wells, etc., to separate the extracted liquid from the sand and gravel in the formation. Due to the basic structural characteristics of the strata involved, the particle size of the sand and gravel in contact with them varies, and the viscosity of the mining liquid varies. The required mesh size and shape of the sieve tube also vary.

In recent years, with the rapid development of China’s petroleum and geological industries, the consumption of sieve tubes has been continuously increasing. With the increase in market demand, coupled with the high difficulty of cutting the holes and gaps in the sieve tube, as well as the high requirements for the geometric size and shape accuracy of the holes and gaps, the difficulty of processing seemingly simple sieve tubes and sieve tubes has increased. At the same time, the “economic” value has also doubled, which has attracted great attention from relevant industries.

The oil screen tube processed by the laser tube cutting machine has thousands of slits. Due to the fact that the pipe laser cutting equipment belongs to thermal processing, its processing must have a starting point, commonly known as “perforation”. Each slit needs to be perforated once, which means that each additional screen tube may need to be perforated tens of thousands of times. Therefore, shortening the perforation time is one of the important means to improve processing efficiency.

In the initial stage of cutting, perforation must be carried out first, and then the laser head (equivalent to a tool in ordinary metal processing equipment) moves from rest to motion for cutting. During the machining process, when the initial perforation of the given laser beam cutting program is given, the laser head transitions from static to motion cutting, and there will be an instantaneous phenomenon of slag reversal. No matter how much slag reversal is, the geometric shape and accuracy of the initial end of the seam will be damaged, resulting in the seam being scrapped. By using multi-level frequency conversion and variable pulse fast piercing technology, the defect rate can be gradually reduced to the minimum, improving productivity and providing reliable guarantees for customers to create higher processing efficiency.

The wall thickness of petroleum slotted screen pipes varies from 3mm to 10mm, and the processing technology varies for pipes with different wall thicknesses. As the wall thickness of the pipes increases, the rate of burst holes increases, and the difficulty of cutting also increases. Especially in the initial stage, the perforation process is one of the key technologies to reduce processing defect rates and improve processing efficiency. Therefore, it is extremely important to find a reasonable configuration of processing parameters among many cutting parameters.