Projects

Detailed Explanation of Laser Welding for Soft Pack Batteries

With the rapid development of new energy vehicles, the soft pack battery, as one of its important components, is increasingly receiving widespread attention. Compared to traditional hard shell batteries, soft pack batteries have the advantages of small size, light weight, and high safety. In the production process of soft pack batteries, laser welding technology has become an indispensable part. This article will provide a detailed introduction to the advantages and applications of laser welding technology for soft pack batteries, including the structure of soft pack batteries, the principle of laser welding, and the application of laser welding machines.

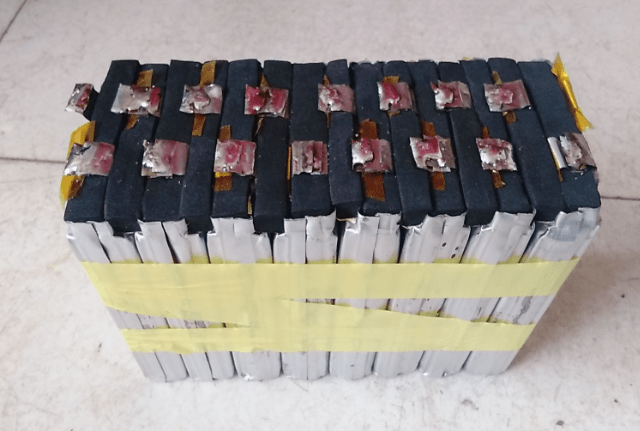

Soft pack battery structure

The structure of a soft pack battery is relatively simple compared to a hard shell battery, mainly composed of several parts such as the battery cell, isolation film, electrolyte, and battery shell.

Principles of Laser Welding

Laser welding is a high-energy density welding technology that uses a laser beam to heat the surface of the workpiece to the melting point, then melt and fuse with each other, thereby achieving the welding effect. Laser welding technology has the characteristics of high precision, high efficiency, and low deformation, and can be widely applied in the welding and cutting of materials such as metals and non-metals.

In the production of soft pack batteries, laser welding technology is mainly applied to the manufacturing and connection of battery cells, as well as the manufacturing of battery shells, with the following advantages:

- High efficiencyTraditional battery connection technology requires the use of multiple tools and a large amount of manual operation, while laser welding technology can be controlled through machine automation, greatly improving the efficiency and consistency of the connection.

- High precisionLaser welding technology can achieve high-precision welding through precise control systems, ensuring consistency and stability of connections, and avoiding problems such as internal short circuits in batteries caused by poor connections.

- Low deformationThe welding heat source of laser welding technology can be concentrated at the welding position, avoiding the thermal effect problem that traditional connection technologies often encounter, namely deformation or thermal damage generated during the welding process.

Application of Laser Welding Machine for Soft Bag Batteries

The soft pack battery laser welding machine is a device specifically used for the manufacturing of soft pack batteries, which can achieve the manufacturing and connection of battery cells, as well as the manufacturing of battery shells.

- Cell manufacturing and connectionThe individual cells in the soft pack battery need to be connected through a laser welding machine to achieve the manufacturing of the battery cells. In this process, the laser welding machine can achieve rapid connection of battery cells through efficient and high-precision working methods, improving production efficiency and consistency.

- Shell manufacturingThe shell of a soft pack battery is usually made of aluminum foil or other composite materials, and the processing and connection of these materials also require laser welding technology. Laser welding machines can provide efficient and high-precision welding methods in shell manufacturing, achieving the manufacturing and connection of shells.

The Application Status of Laser Welding Technology for Soft Pack Batteries

At present, the laser welding technology for soft pack batteries has been widely applied in the new energy vehicle and battery industries. Many well-known domestic and foreign enterprises, such as Tesla, LG, Panasonic, etc., have adopted laser welding technology on their production lines, improving production efficiency and battery quality.

The development of soft pack batteries is an important direction for the development of new energy vehicles. The application of laser welding technology can not only improve the production efficiency and quality of soft pack batteries, but also promote technological innovation and industrial progress in the battery industry. In future development, laser welding technology will play a more important role, bringing more possibilities for the development of new energy vehicles and battery industries.

About HGSTAR: HGSTAR is is a sub-brand of HGTECH.HGTECH the pioneer and leader of laser industrial application in China, and the authoritative provider of global laser processing solutions. We have comprehensively arranged laser intelligent machine, measurement and automation production lines, and smart factory construction to provide overall solutions for intelligent manufacturing.