Projects

What Molds can Laser Cleaning Equipment Clean?

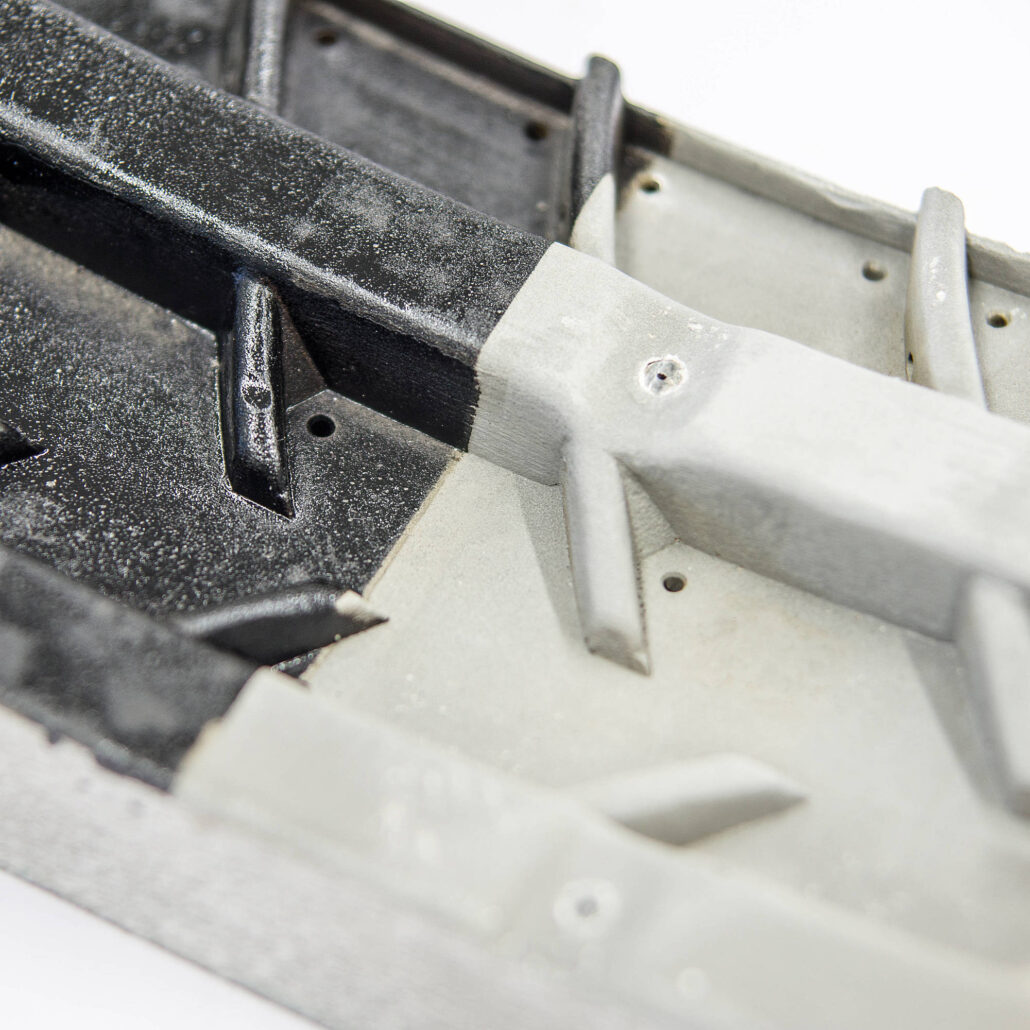

Moulds play a very important role in industrial production. Mold cleaning is the key to maximizing the service life of molds, improving the reliability of molds, and ensuring product quality. Mold cleaning is a key process in mold maintenance and is also a bottleneck that restricts mold maintenance.

After the completion of production operations, general molds need to be cleaned after demolding. How should the mold surface be cleaned without damaging the substrate after demolding? The traditional method is for production workers to brush and wash the molds one by one with frosted paper. This method is time-consuming, labor-intensive, labor-intensive, and involves numerous steps, not to mention the inability to clean the fine seams, corners, and pores. Therefore, this method is being phased out by more and more factories.

With the development of the times, an increasingly scientific and efficient method is to use professional laser cleaning machines to clean molds. For the production of rubber, silicone, stamping and other types of molds, attachments can be completely removed in an instant, making it easy to use. This product does not damage the mold during cleaning, and can also extend the use time of the mold, reduce the cost of mold maintenance and improve the efficiency of mold cleaning.

Sealing ring mold cleaning, rubber mold cleaning, wheel hub mold cleaning, stamping mold cleaning, and so on. In the cleaning operation, many enterprise employees express that the laser cleaning machine cleans faster and has better results, and the equipment operation is simple, does not damage the mold, and the cleaning efficiency increases exponentially.

In the constantly improving mold industry, controlling product quality has become particularly important.

Advantages of Laser Cleaning for Tire Mold Cleaning

Tire molds are an essential tool for producing tires. Without molds, tires cannot be formed. Tire mold cleaning is a daily task that tire factories need to do. The cleanliness of tire mold cleaning determines whether the tires produced are qualified. Currently, tire mold cleaning methods include sandblasting, dry ice, chemical cleaning, and laser cleaning, although this is a new cleaning process, However, existing tire factories are gradually replacing the original cleaning process with laser cleaning because laser cleaning has the advantage of environmental protection, efficiency, pollution-free, and zero damage.

The advantage of laser cleaning is that as long as the light can reach the area, it can be cleaned clean. The traditional cleaning process has a poor working environment and can cause certain harm to operators. Some cleaning processes can cause damage to tire molds when used too much, so existing tire factories only seek new cleaning processes to replace traditional cleaning processes.

The benefits of laser cleaning for tire inner wall cleaning

The new technology of tire inner wall cleaning – laser cleaning, can meet the cleaning requirements without damaging the inner and outer surfaces. The purpose of cleaning the inner walls of tires is to apply silent cotton to the inner walls of tires. Due to the rise of new energy vehicles, tires need to have noise reduction effects. Therefore, high-end silent tires have become the preferred choice in the industry. Before applying silent cotton, the inner walls of tires need to be unglazed and the isolation layer cleaned. Early on, it was manually wiped with alcohol, which is inefficient, unstable, and poses a risk of flammability and explosion, and is not environmentally friendly.

The advantage of laser cleaning is that it does not require consumables, is more economical, environmentally friendly, has less damage to materials, can almost achieve non-destructive cleaning, and is convenient for automated integration.

About HGSTAR: HGSTAR is is a sub-brand of HGTECH.HGTECH the pioneer and leader of laser industrial application in China, and the authoritative provider of global laser processing solutions. We have comprehensively arranged laser intelligent machine, measurement and automation production lines, and smart factory construction to provide overall solutions for intelligent manufacturing.