Projects

Advantages of Glass Laser Cutting Technology and Its Application in the Automobile Manufacturing Sector

Glass, as an important industrial material, is applied across various sectors, including household appliances, sanitary ware, decoration, electronics, crafts, optics, construction, automobile, photovoltaic etc. It is used in products ranging from small optical filters measured in micrometers to large-scale glass panels used in automobile, photovoltaic, and construction industries.

Laser Cutting vs. Traditional Glass Cutting Methods:

Glass, being a typical brittle material, presents significant challenges during processing. Traditional glass cutting methods involve the use of hard alloy or diamond tools, which come with certain drawbacks. Using this method for scoring and cutting results in the generation of debris, fragments, and micro-cracks due to material removal. This diminishes the strength of the cutting edges, necessitating an additional cleaning step.

The advancement of laser technology provides solutions to these quality issues. Unlike traditional mechanical cutting tools, the energy of a laser beam cuts glass in a non-contact manner.

Glass laser cutting technology offers extremely high precision, achieving micron-level positioning accuracy. This allows for the precise cutting of various complex parts and components during the automobile manufacturing process, enhancing product quality and consistency. Moreover, glass laser cutting machines operate at high speeds, significantly reducing production cycles. Additionally, the high level of automation reduces manual labor, thus lowering production costs. Furthermore, due to the high precision, it minimizes material waste, thereby improving resource utilization.

The Application of Glass Laser Cutting Technology in Automobile Manufacturing

Throughout the evolution of the automobile industry, each technological innovation has brought us safer, more efficient, and more aesthetically pleasing vehicles. Today, with the continuous maturation of laser cutting technology, glass laser cutting machines have emerged as shining stars in the field of automobile manufacturing.

1. Manufacturing of Window:

Glass laser cutting machines play a crucial role in the manufacturing of car window. By controlling the energy and timing of the laser beam, these machines can achieve precise cutting of window glass, ensuring dimensional and shape accuracy. This not only enhances the sealing and safety of windows but also provides automobile designers with more creative freedom.

2. Manufacturing of Interior Components:

Glass laser cutting technology also plays a significant role in the manufacturing of interior components for automobiles. For instance, the production of dashboard, center console, and other interior components often requires high-precision cutting technology. Because of that, glass laser cutting machines can accurately cut various complex interior components, enhancing the aesthetics and comfort of the interior.

3. Lightweight Materials:

With the increasing awareness of environmental protection, lightweighting has become an important trend in automobile manufacturing. Glass laser cutting machines can process lightweight materials such as carbon fiber and aluminum alloy. These materials enjoy wide application prospects in automobile manufacturing industry, as they can reduce vehicle weight, improve fuel economy, and enhance driving performance.

4. Customization:

Glass laser cutting machines also offer manufacturers the possibility of customization. By precisely controlling the path and shape of the laser beam, glass laser cutting machines can create various unique patterns and text on glass, meeting consumers’ personalized needs.

HGTECH Automobile Glass Laser Processing Automated Production Line

“Large format, one cut!”

Large format + High efficiency + High precision

Material-saving: Achieve a 20% increase in material utilization rate

Intelligent: Intelligent sorting, quick changeover

Environmentally friendly: No consumables required, immune to cutting fluid pollution

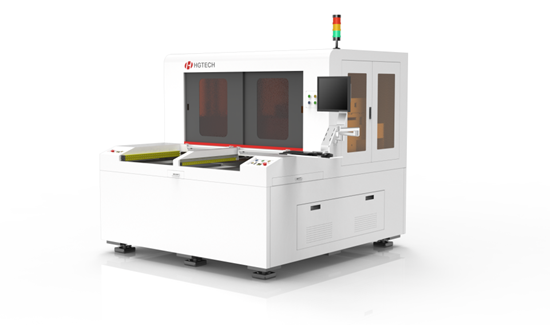

Ultra-Thin Glass (UTG) Cutting Equipment

“Cutting irregular shapes, cutting ultra-thin glass, nothing is beyond reach.”

High efficiency: Utilizing dual loading shafts to enhance laser cutting efficiency.

High quality: Employing infrared picosecond technology, ensuring good beam quality, small focused spot, and high power stability.

Fast speed: Equipped with high-speed, high-precision linear motors, enabling fast cutting speed and high accuracy.

High stability: Utilizing a marble base to ensure stability of the optical path system.

High compatibility: Capable of accommodating cutting for various models and product sizes.

In response to the comprehensive demands of the glass processing industry, HGTECH seizes the opportunity of industrial development, creatively establishing three major technological platforms: laser cutting, laser drilling, and laser engraving. With a range of specialized equipment exceeding 20 types, we have successfully tackled industry technical challenges such as glass laser chamfering and rough surface microcrystalline glass cutting.

In the future, addressing the increasing demand for intelligent applications like AR/VR and new materials such as optical waveguide materials, HGTECH will continue to closely follow market demands and introduce specialized, high-quality, and innovative products to enhance the quality and speed of development in the electronic glass processing industry.