News

Optics Guide the Future | HGTECH Appears at the 2024 China Optics Valley Optoelectronic Information Industry Innovation and Development Forum

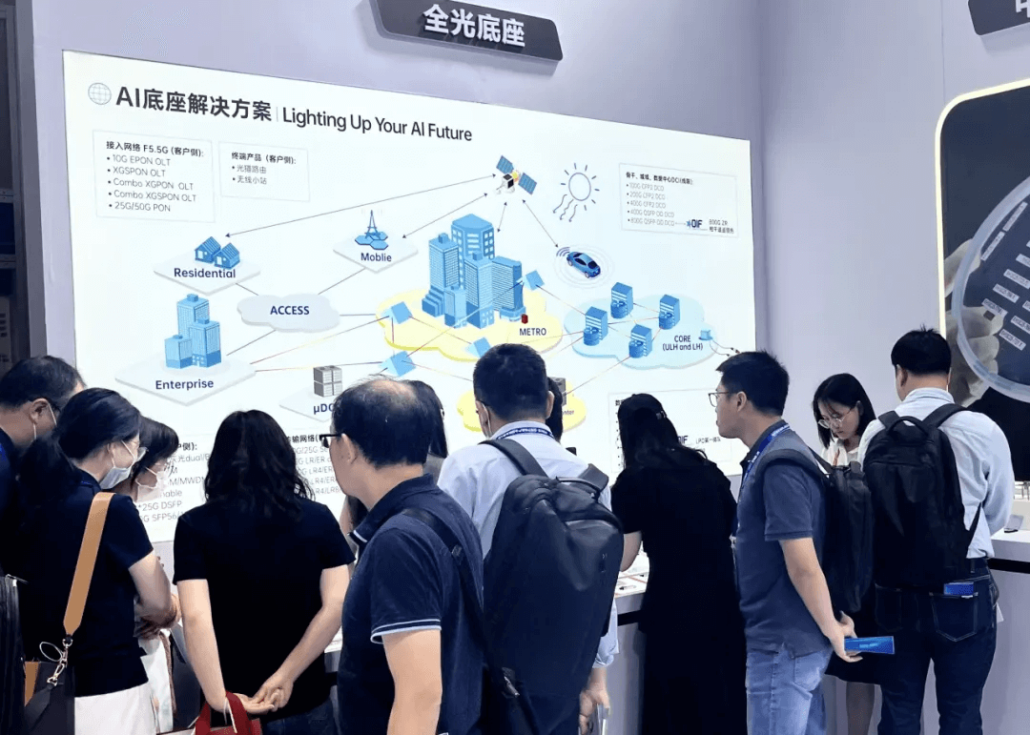

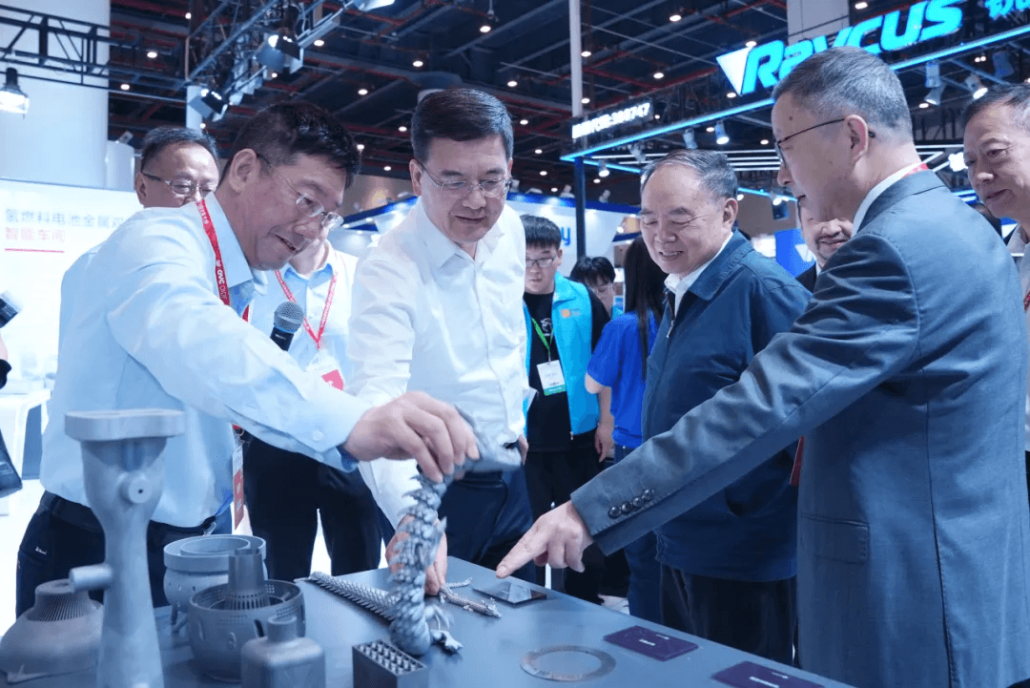

On May 16th, 2024 China Optics Valley Optoelectronic Information Industry Innovation and Development Forum opened at the China Optics Valley Convention&Exhibition Center. HGTECH showcased its optical communication and laser+intelligent manufacturing solutions at the exhibition. Its core subsidiary, HGGenuine, presented products such as the 1.6T high-speed silicon optical module focusing on optical communication + AI base solutions. Sheng Yuechun, Vice Governor of Hubei Province, and Zhou Ji, academician of the Chinese Academy of Engineering, visited the booth for guidance.

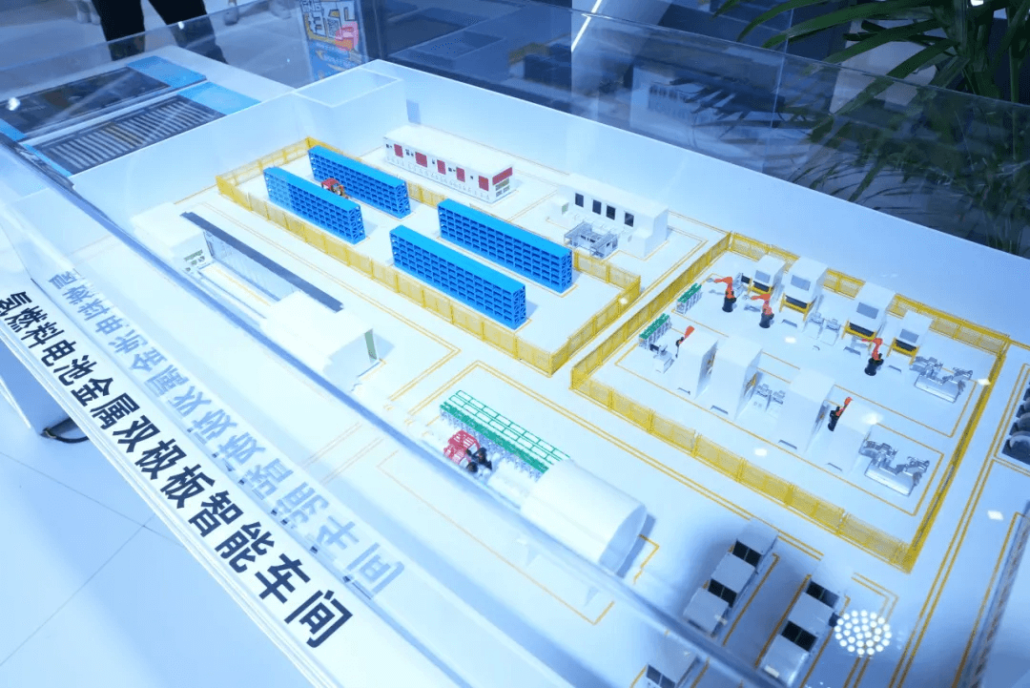

Smart Factory “Moves” into Exhibition Hall

The smart factory model for heavy industry exhibited on site is an important case designed by HGTECH for Taiyuan Heavy Industry. The model consists of five core production lines: sheet metal cutting line, profile cutting line, welding line, painting line, and assembly line. It showcases the production process, line layout, logistics planning, and other content of the heavy industry, allowing visitors to intuitively experience the technological charm and unlimited potential of the intelligent factory in the heavy industry.

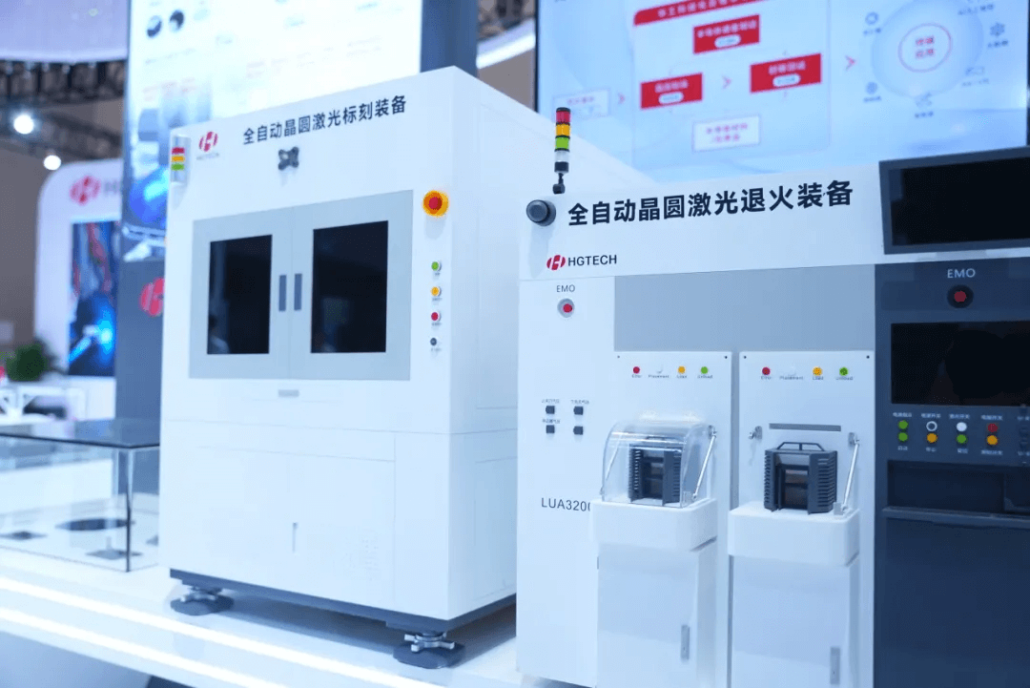

The Advancement of Domestic Production

LUA3200, a fully automated wafer laser annealing equipment independently developed by HGTECH, is capable of annealing the transition metals deposited on the back of heavily doped SiC wafers. It not only enhances the uniformity of annealing to 95% and increases efficiency by 30%, but also ensures a safer and more controllable supply chain for core components. The laser semiconductor team of HGLaser collaborates with the research team from the School of Mechanical Engineering of Huazhong University of Science and Technology, completing the development of unit technology, overall machine design, assembly, and debugging. The localization rate of the equipment exceeds 80%.

Currently, the equipment is in the debugging stage, with plans to be delivered to Fab for validation and initial sales of the first sets expected in the second half of this year.

Three Iterations Within Three Years, the Yield Increased by 1.5%.

In 2021, HGTECH launched hydrogen-powered metal bipolar plate welding equipment. Over the subsequent three years, three iterations were completed to optimize the equipment, resulting in a 1.5% increase in yield and achieving a breakthrough in orders. The good welding sealing of bipolar plates has a significant impact on the overall performance and lifespan of the stack. Utilizing laser technology can effectively improve the quality and efficiency of welding, ensuring the reliability and stability of fuel cell products.

Turning Beam into Gold! Efficient, Energy-Saving, Cost-Reducing

HGTECH focuses on SLM (Selective Laser Melting) technology, independently developing LSP series metal 3D printing intelligent equipment. Featuring a scraper-type bidirectional powder spreading system and a multi-laser overlapping control system, it achieves higher forming efficiency, reducing tooling costs and minimizing material waste. From tiny intricate components to various material structures, lasers, with their small beam diameter and strong controllability, can print finer and more complex geometric shapes and structures. Taking automobile manufacturing as an example, rapid integrated forming of complex geometric components greatly reduces the number of parts for assembly, further achieving lightweight vehicle.

High-Speed Optical Module Products Shine at the Exhibition

Previously, at the Optical Fiber Communication Conference and Exhibition (OFC) in the United States, HGGenuine unveiled a 1.6T high-speed silicon optical module featuring self-developed silicon optical chips, attracting widespread industry attention. The 1.6T high-speed silicon optical module products launched by HGGenuine adopt self-developed single-wave 200G silicon optical chips and are compatible with thin-film lithium niobate modulators and quantum dot lasers. They feature 8 parallel transmission and reception channels, with expected energy consumption reduction of 40% compared to traditional 1.6T optical module products.