Projects

High Efficiency Fiber Laser Cutting Machine Component Collaboration

Preface

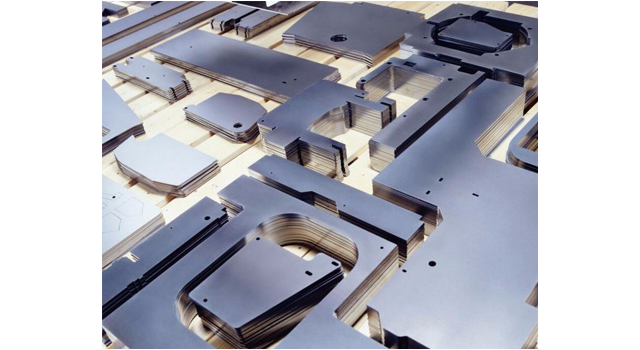

Each component of the fiber laser cutting machine is responsible for different functions and is indispensable. Each component coordinates to complete the cutting action of metal materials.

Machine tool

The machine tool matched with high-power lasers must be a high-speed machine tool with high dynamic performance.

Higher laser power means faster operating speed and acceleration. With the development of lasers towards high power and the adoption of high-performance CNC and servo systems, the use of high-power laser cutting can achieve high processing speeds while reducing the heat affected zone and thermal distortion; The thickness of the material that can be cut is further increased, and high-power lasers can generate high-power lasers by using Q-switches or loading pulse waves, such as 12kw fiber laser cutting machines.

New software and control system

Software and control systems are like the brain and command center of machine tools. In addition to the dividends brought by hardware upgrades, the differences in overall performance of machine tools mainly come from the differences in software and control systems, and often have huge differences.

Professional laser cutting software with multi-level permissions for easy production management; Equipped with graphic layout and sharp corner smoothing processing functions, it can achieve intelligent production of high-speed cutting, welding, punching, and marking functions. The operating system includes a dual screw and dual motor drive system, which can effectively improve production efficiency and run at a speed of up to 1000mm/s.

Fiber laser cutting machines will develop towards high automation and intelligence. Applying CAD/CAPP/CAM and artificial intelligence to laser cutting, a highly automated multifunctional laser processing system has been developed.

Laser cutting head

The laser cutting head is the key to achieving long-term stable cutting under high-power continuous working conditions.

Compared with ordinary cutting heads, it requires stricter sealing and more sufficient cooling measures, a wider focus range, and higher temperature resistant coated lenses. Due to the high-power thermal lens effect, the laser cutting head experiences focal drift of the beam during long-term operation. Overcoming focal drift is an important challenge for high-power laser cutting equipment. HGTECH’s 12kw fiber laser cutting machine uses updated pneumatic design and new nozzles to improve the cutting speed and stability of thick plates.

Epilogue

In addition, safer and more reliable bed thermal protection is also a factor that needs to be reconsidered. In addition to upgrading the software and hardware aspects of the host bed and control system, a large number of supporting designs and improvements, as well as more comprehensive research on laser cutting technology, are all technical points that high-power laser cutting equipment must overcome.