Projects

How to choose your own laser cleaning machine

How to choose your own laser rust removal machine

With the rapid development of laser cleaning technology, laser rust removal machines have progressively entered people’s lives with their distinctive benefits of little damage, high cleaning accuracy, zero emissions, and pollution-free. There is little doubt that the use of laser cleaning technology to remove grime from metal surfaces has enormous potential. However, the market pricing for laser cleaning devices range from tens of thousands to hundreds of thousands of dollars. It is critical to understand how to select the best laser rust removal machine for you.

1. What exactly is a laser cleaning machine?

The portable laser cleaning machine focuses on cleaning and protecting the equipment that requires cleaning. Laser cleaning technique is a “green” cleaning method that does not require the use of any chemical agents or cleaning solutions. The waste materials cleansed are essentially solid powder, tiny in size, easy to store, and recyclable, allowing chemical cleaning to readily handle the environmental pollution problem.

According to a large number of testing data, the laser cleaning machine differs depending on the thermophysical characteristics of the surface attachment and the substrate:

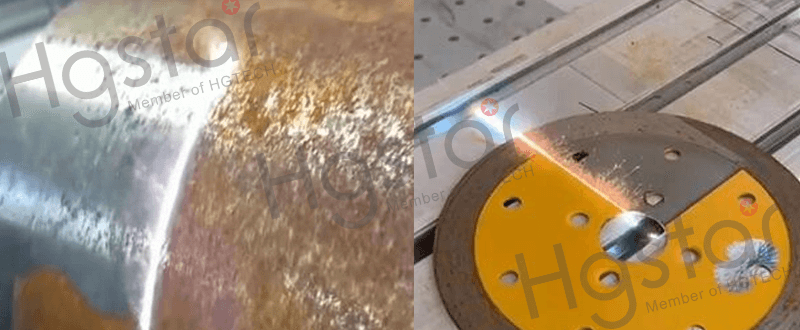

When the thermophysical parameters of surface attachments are significantly different from those of the base material, the laser cleaning machine includes ablation vaporization, thermal vibration and thermal shock machine, and acoustic vibration crusher, such as laser cleaning paint layer and rubber layer.

When there is little difference in the thermophysical properties of the surface attachment and the base material, the ablation vaporizer, such as laser rust removal, is primarily used.

2. The use of a laser cleaning machine

Laser cleaning technology is currently being used in the military, mold cleaning, surface treatment, microelectronics, cultural relic protection, medical treatment, vehicle processing, and other industries.

2.1 Military utility

In the field of aerospace, American scientists proposed and conducted relevant research on the use of laser to remove paint from military aircraft. It has now been applied effectively to the complete F16 fighter. The laser paint removal procedure requires no consumables and has a minimal operating cost. It ensures the safety and quality of aircraft maintenance. The paint layer on the surface of an A320 Airbus may be completely removed in two days using numerous laser cleaning devices without affecting the metal surface.

Laser cleaning can increase the efficiency of equipment maintenance, minimize oxidation on the surface of weapons and ammunition, and give a strong guarantee for military equipment and military combat effectiveness in the maintenance and fabrication of military equipment.

2.2 Commercial application

The tire mold is polluted during the use process by the comprehensive deposition of rubber, compounding agent, and release agent, which will inevitably result in carbon deposition, viscose, difficult demoulding, and other problems, causing the pattern pollution dead zone and affecting mold life and tire quality.

Laser cleaning technology can not only improve tire mold cleaning by removing residual pollutants on its surface, but it can also increase tire surface performance and hence indirectly improve tire production quality.

According to a cleaning test of laser cleaning equipment on a tire company’s production line, it only takes 2 hours to clean a set of huge truck tire mold online; the economic savings are clear when compared to conventional cleaning methods.

The use of laser cleaning technology in industry has substantially enhanced the carbon removal impact and the quality of the welding process. It can efficiently clear carbon deposition on various substrate surfaces, decrease welding flaws, and increase material weldability; at the same time, it may cut enterprise production costs and improve enterprise production efficiency.

2.3 Additional applications

Lasers are used to remove oxides in the electronics industry. To achieve the best electrical contact, the component pins must be properly deoxidized before welding the circuit board, and the pins cannot be damaged while decontaminating. Laser cleaning can satisfy the needs of the user and is highly efficient. One pin just needs to be laser-irradiated once.

Laser cleaning of cultural treasures, handicrafts, and architecture is becoming increasingly popular. People in Europe have cleaned numerous buildings, including the martyr’s grave in Poland and the West Executive Palace in London. However, not all cultural items, such as colorful handicrafts, can be cleaned by laser. Because different colors have distinct laser absorption spectra, the absorption energy varies, and the part+ with high energy absorption will be harmed.

3. Laser cleaning machine cost

Because laser cleaning machines are often customized, it is difficult to have a fixed price for them. In general, the price of a laser cleaning machine is proportional to its power. The more powerful the laser, the more expensive the price. However, laser cleaning machines should be purchased depending on their individual needs, such as easy cleaning of floating rust, which can be handled by low-power laser cleaning machines, whereas high-power laser cleaning machines may cause workpiece damage.

To achieve the best cleaning effect on the corresponding substrate to be cleaned, the corresponding optical fiber length, field mirror focal depth, output power, pulse width, scanning speed, and other parameters must usually be adjusted according to the characteristics of different substrates.

The price of a composite laser cleaning machine of more than 8000W, which is used to remove paint off huge equipment such as aerospace and high-speed rail, is commonly established after field measurement.

4. Laser cleaning machine scope

Hand-held laser cleaning machines and large desktop laser cleaning machines are the two types of laser cleaning machines. Different laser cleaning devices are useful for different tasks and locations. Some hand-held laser cleaning machines, for example, are only suited for semiconductor equipment since the semiconductor environment requires stronger environmental protection and chemical contaminants are not permitted. Some huge ships, however, are an exception. Different contexts will result in varying degrees of application scope. We can only accomplish the intended impact by using targeted and appropriate cleaning equipment.

5. Laser cleaning machine manufacturer

A series of service issues will be associated with the manufacturer qualification of laser cleaning machines. Laser cleaning equipment has certain process requirements as a cleaning machine. The cost of industrial equipment will vary substantially depending on the procedure. It is recommended that you consider the manufacturer qualification of laser cleaning equipment before purchasing it. It is necessary to re-identify their capabilities by following up with existing cooperative consumers.

HGSTAR is China’s laser industrial application pioneer and leader, as well as the authoritative provider of global laser processing solutions. To provide a complete solution for intelligent manufacturing, we meticulously plan the development of laser intelligent equipment, measurement and automation production lines, and smart factories. It offers full power laser cutting systems, laser welding systems, laser marking systems, laser texturing complete sets of equipment, laser heat treatment systems, laser drilling machines, lasers and various supporting devices, laser processing special equipment, and plasma cutting equipment to a variety of industries, as well as an overall plan for the construction of automatic production lines and smart factories.

6. Following the sale of a laser cleaning machine

We must prioritize after-sales servicing for this type of industrial equipment. After all, its technical and technological requirements are great, which regular after-sales service cannot meet. It is also critical to select reputable companies, such as Huagong Laser. People may meet a range of issues for the first time, such as whether the operation problem occurs during use or the difficulty of not comprehending the debugging in the environment. It will substantially simplify the process if you can quickly locate after-sales professionals to solve the problem and technicians to visit.