Projects

Industry Applications of Industrial Laser Cutter(II)

Introduction

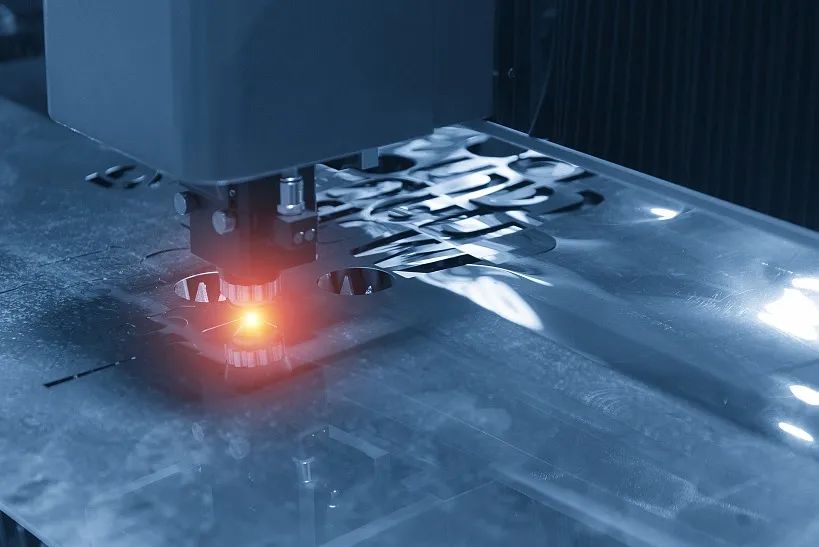

The laser cutting technology of the industrial laser cutter is to use the focused high power density laser beam to irradiate the workpiece, so that the irradiated material quickly melts, vaporizes, ablates or reaches the ignition point, and at the same time, the high-speed air flow with the beam coaxial blows away the molten material, so as to achieve the workpiece cutting, which belongs to one of the thermal cutting methods, widely used in the construction machinery industry.

Application of industrial laser cutter in sheet metal parts reservation process gap

The process gap reserved for sheet metal parts is also called the crack slot or process hole. The design of the gap in sheet metal production generally has three forms: the first is that two or more bending parts are adjacent; The second is that one of the edge bending parts is completely bent in the direction of length.

For the second kind of process gap, the traditional form will set aside a×b rectangle, if the use of industrial laser cutting machine in the cutting position directly cut out the length of a slit can be, for some high requirements of the workpiece can be used industrial laser cutter directly reserved slit form.

The third form, when the sheet metal can not be bent in the bending machine at both ends of the die above the support in the hanging position when the workpiece will be deformed, in this case, the industrial laser cutting machine can be used to reserve a slit when the workpiece is cut to prevent the workpiece from deformation during bending.

Application of industrial laser cutter in making sheet metal templates and drilling templates

In some sheet metal parts in the construction machinery industry, for some irregularly shaped workpieces, in order to improve the accuracy and efficiency of the detection of the parts, industrial laser cutting machines are used to make the cutting test template, such as the support Angle on the bulldozer, the big head plate on the excavator bucket rod and the boom.

For some coil forming workpiece, in the workpiece production and detection need to use and arc matched template to assist production and detection, in order to improve the accuracy of workpiece production and detection efficiency, usually, the use of laser cutting to produce these workpiece template, and the use of industrial laser cutting machine marking function on the template marked arc and straight edge boundaries, Such as the curved plate of the bulldozer, the bending plate of the bucket rod and the boom of the excavator and the digging bucket.

Future development of laser cutter

Although industrial laser cutter has been widely used in the field of construction machinery, its future development still has great potential. With the continuous progress of science and technology and the increasing demand for applications, industrial laser cutting machines will face more market opportunities and challenges.