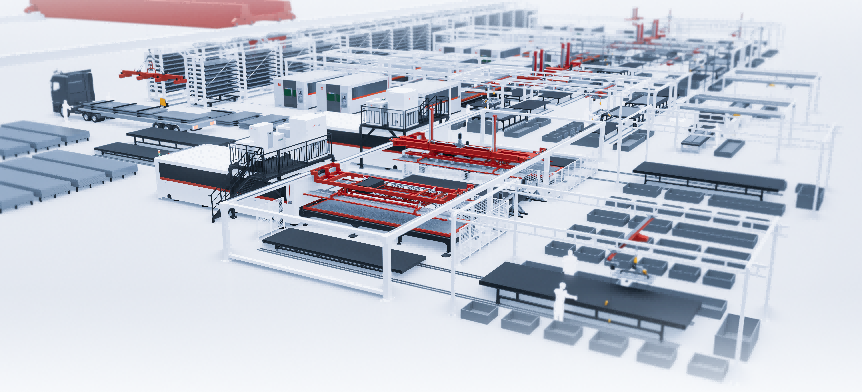

In today’s landscape, traditional manufacturing is rapidly advancing toward smart, digital transformation, with laser automation systems playing a crucial role as a foundation of future smart factories. HGTECH provides cost-effective laser cutting machines along with proprietary automated loading and unloading systems, automated sorting systems, monitoring systems, and intelligent storage systems—effectively addressing sheet metal storage challenges and offering comprehensive intelligent manufacturing solutions for sheet metal processing.

A well-designed automatic material storage system significantly enhances material handling capacity, boosts production efficiency, and reduces labor, costs, time, and space. Compared to traditional discrete manufacturing, an laser automation line increases production capacity by 200% and improves floor space utilization by 40%.

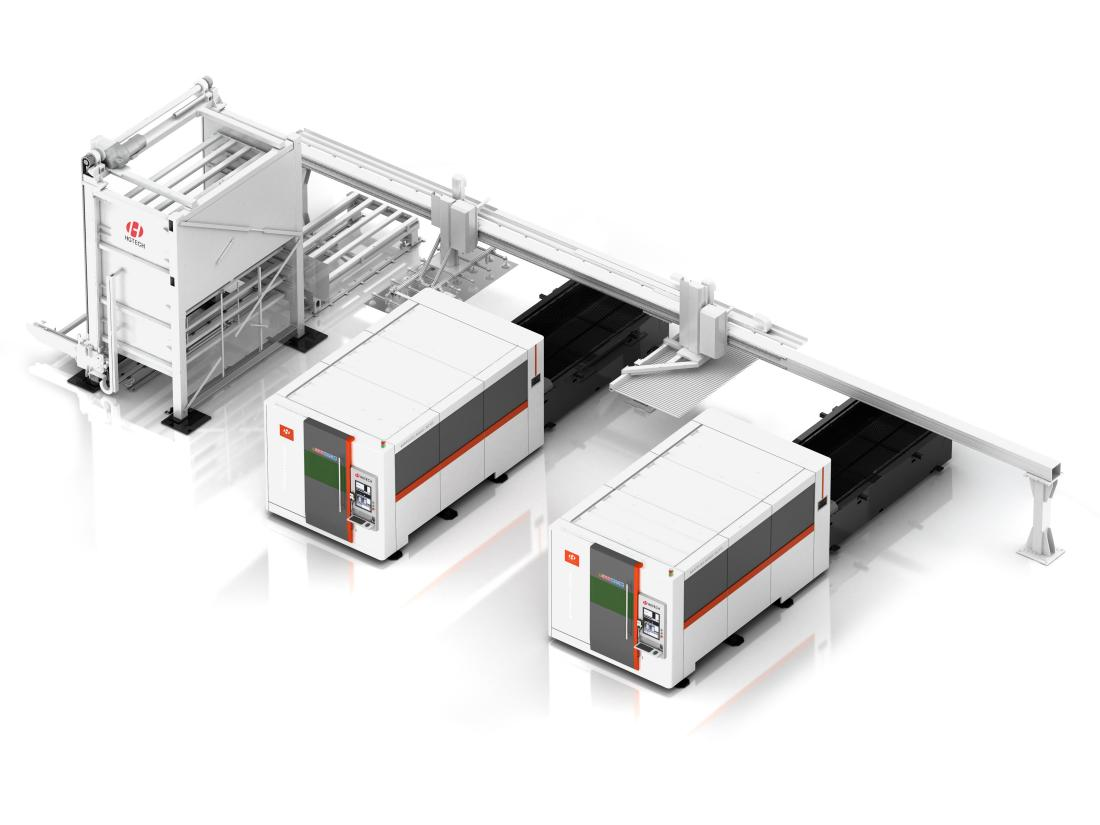

HGTECH flexible laser cutting automation line comprises multiple laser cutting automation storage units. Each unit includes a storage system, an automated loading and unloading system, and a production line operation and monitoring system, compatible with 1-3 laser cutting machines. The automated storage system can store and retrieve materials without direct manual intervention.

The laser automation line also integrates robotic bending systems, laser welding tables, RGV and AGV transport systems, and other functional modules, all managed and scheduled through the HG-PMS platform.

| Modular design with high reliability and automated operation |

- Repaces manual handling by automatically gripping sheet materials, enhancing processing accuracy and quality

- Compatible with most laser cutting machine brands and customizable to meet different requirements

| Multi-mode production for high efficiency and safety |

- Adapts to various production modes, providing real-time material supply and optimizing space usage

- Supports single-sheet feeding with individual sheet detection and anti-drop functionality

| Scratch Protection for Sheet Material |

- Optional pronged protective belt to prevent workpiece scratches

- Ensures smooth operation and prevents sheet slippage during unloading

| 24/7 continuous operation |

- Precise positioning with automated material handling

- Data integration, synchronized workflows,and dimensional precision