Projects

Processing and Application of Electronic Components for New Energy Vehicles

The emergence of new technologies such as new energy vehicles, intelligent driving, and vehicle networking has transformed cars from simple transportation tools into highly integrated mobile smart terminals. In this process, electronic components for automobiles play a crucial role as they are the key support for implementing these advanced technologies.

The electronic components industry provides corresponding component products for the automobile manufacturing industry, serving as the foundation for the development of the automobile industry and an important part of the automobile supply chain. A typical car consists of four main parts: the engine, chassis, body, and electrical equipment. Various segmented products within the automobile component industry are derived from these. In the field of new energy vehicles, the introduction of core components such as batteries and motors has led to changes in the types and quantities of automobile components.

The rapid penetration of new energy vehicles has also driven the expansion of automobile components towards electrification, intelligence, and lightweighting. The development of electric vehicles has had a significant impact on traditional fuel vehicles, forcing automobile component companies to accelerate their pace of technological innovation and product upgrades.

Currently, under the advancement of smart technology, autonomous driving is continuously evolving, leading to increased consumer demands for products. Smart, lightweight, and miniaturized designs have become mainstream in development, with a growing emphasis on precision in manufacturing processes.

As refinement, high-density, and high-performance trends continue, the non-contact, lossless processing of precision laser are increasingly applied within the automobile electronic components industry. HGTECH closely follows the trend of intelligent manufacturing, striving to create smart factories one-stop solutions , reducing production costs, and enhancing product quality and production efficiency for new energy vehicle manufacturing.

Automobile Electronic Components – Laser Marking

- Laser marking provides unique advantages for electric vehicle manufacturing:

- Laser systems feature self-protection temperature switches and comprehensive alarm mechanisms.

- Utilizes a “cold” processing method, suitable for a wide range of materials; ensures stable product quality.

- UV series suitable for marking various materials including plastics, metal, and glass; CO2 series applicable for marking, cutting, and perforating various non-metal materials.

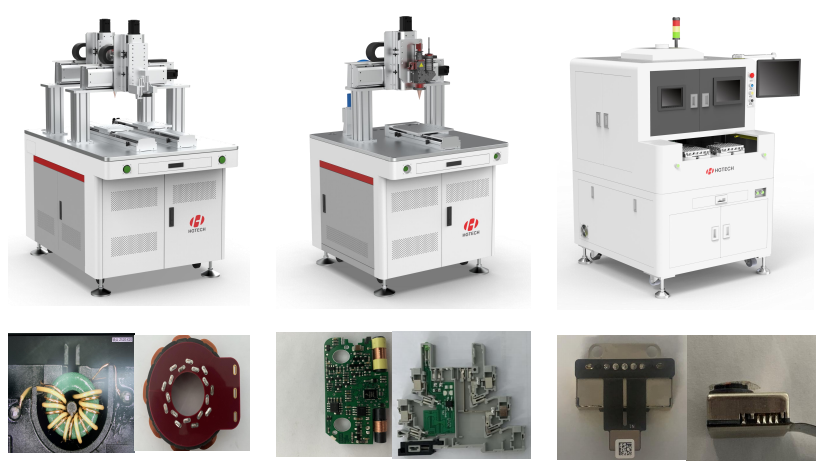

Fiber Marking System UV Marking Equipment CO2 Marking Equipment

Automobile Structural Automobile Connectors Automobile Leather

Components Metal Marking Plastic Marking Plastic Marking

Automobile Electronic Components – Laser Welding

Laser welding provides unique advantages for electric vehicle manufacturing:

- Excellent light beam quality ensures high welding quality and superior sealing effects

- Coaxial gas protection device ensures consistent welding quality.

- Highly integrated modular design facilitates automation.

- High depth-to-width ratio enables both spot welding and continuous welding of metals.

CW Continuous QCW MOPA

Laser Welding Equipment Laser Welding Equipment Metal Welding Equipment

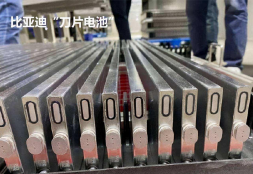

Automobile Camera Automobile Connector Automobile Metal Sheet

Solenoid Valve Welding Pin Welding Welding

Constant Temperature Automatic Wire Loading Automatic Solder Ball Jetting

Solder Paste Laser Welding Welding Equipment Welding Equipment

Electronic Component Automobile PCB Board Welding Automobile Camera Welding

Pin Welding

Application:

- Power Battery

- Solenoid Valve

- Sensor

- Flat Wire Motor

- Camera Radar