Projects

Sheet metal processing solutions

China is gradually becoming an international processing and manufacturing center, and the demand for metal processing is increasing, while electrical control boxes and machine housings in the metal processing industry are generally sheet metal parts, so the demand for sheet metal processing capacity is also increasing.

Therefore, the demand for sheet metal processing capacity is also increasing, and with this, the complexity of the process is also relatively high, even some parts have as many as several dozens of processes, which also puts forward higher requirements for sheet metal processing in terms of accuracy.

Traditional sheet metal processing has processes such as shearing, punching and bending, among which the punching process requires a large number of dies, which wastes a lot of time and capital costs.

Laser cutting is an efficient and high quality flexible processing process. Laser sheet metal processing does not require tooling, and compared to traditional processing means, it is simple to operate, more flexible, and has lower operation and maintenance costs.

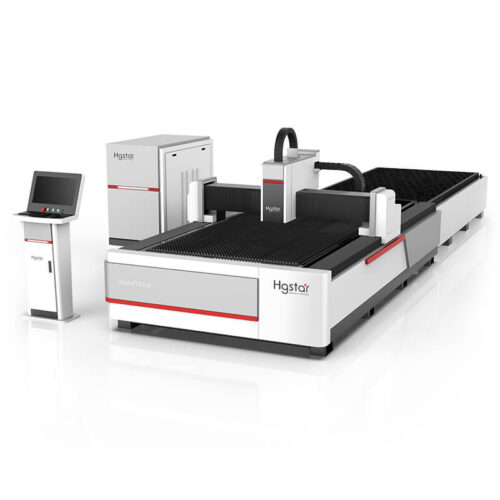

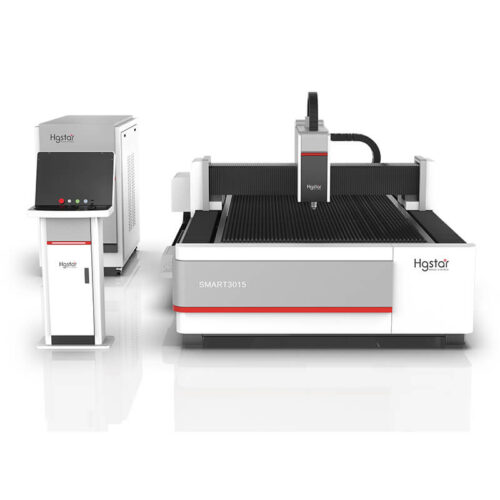

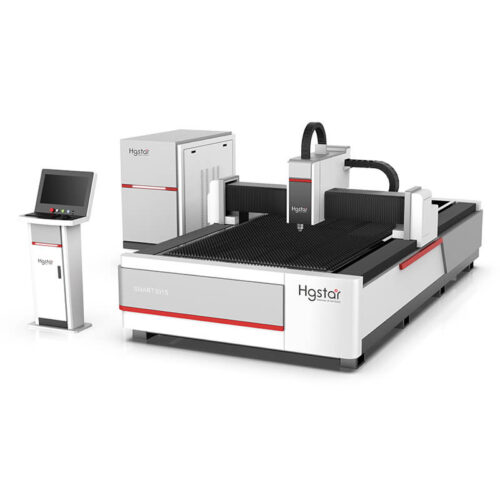

Huagong Falilai has innovated and upgraded the laser cutting technology accumulated for many years, and launched a variety of advanced laser cutting equipment to provide efficient and professional laser sheet metal processing solutions for the sheet metal processing industry, and finally to maximize the value of customers.

Traditional sheet metal cutting equipment and process flow

The conventional sheet metal processing process is: shear – punch – bending – welding process or flame plasma cutting – bending – welding process. It has obvious deficiencies in the face of multi-species, small batch, customized, high quality and short delivery time orders:

● (CNC) shearing machines can only be used for sheet metal processing where only linear cutting is required, due to their mainly linear cutting.

● (CNC/brick tower) punching machines have limitations for cutting sheet metal with thickness above 1.5mm and have poor surface quality, high cost, noise and are not conducive to environmental protection.

● Flame cutting, as the initial traditional cutting method, has large thermal deformation and wide slit during cutting, wastes materials, has slow processing speed and is only suitable for rough processing.

● High pressure water cutting processing speed is slow, causing serious pollution and high consumption cost.

New Sheet Metal Cutting Equipment and Process Flow – Laser Cutting

Laser cutting is a process revolution in sheet metal processing and is the “processing center” in sheet metal processing. Laser cutting process has the advantages of flexibility and high flexibility. In view of the problems of traditional sheet metal cutting at this stage, the demand for laser cutting is also increasing.

The advantages of the new sheet metal cutting process are.

● High degree of flexibility in laser cutting, fast cutting speed, high production efficiency, short product production cycle, whether simple or complex parts can be cut in one quick form by laser.

● Narrow cutting slit, good cutting quality, high automation, easy operation, low labor intensity and no pollution.

● Automatic nesting and nesting of cutting can be realized, which improves the material utilization rate, no tool wear, and good material adaptability.

● Low production cost and good economic efficiency.

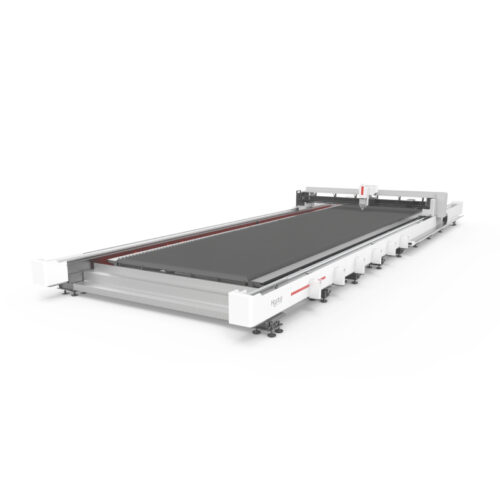

Most of the sheet metal processing for large and medium-sized enterprises to do supporting, the user’s products vary, high requirements, urgent goods, so it is recommended to use high power, large format laser cutting machine. High power, enhance the cutting capacity at the same time, also enhance the cutting efficiency; large width, high material utilization, while meeting the cutting needs of different widths.

Recommended solutions

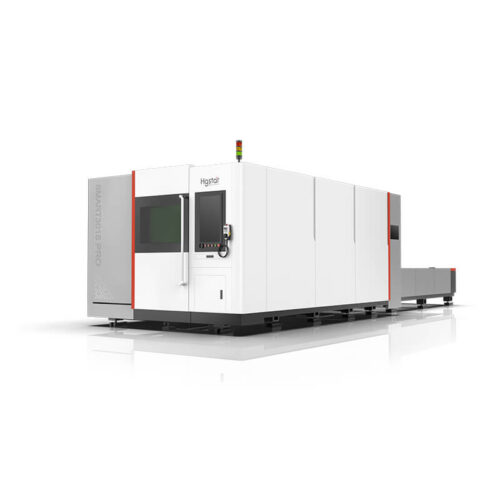

HG farley SuperCut bright surface cutting technology, can be grafted to the conventional 3-6m format models, can also match Huagong Falilai large format 3-24m large format WALC series, taking into account the wide range of products in the sheet metal processing industry and different customer needs, it is recommended to match the power laser above 3000 watts, which can solve the cutting of carbon steel within 20mm and stainless steel within 10mm.

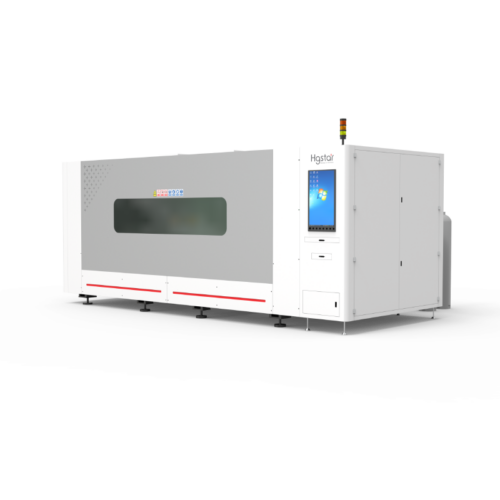

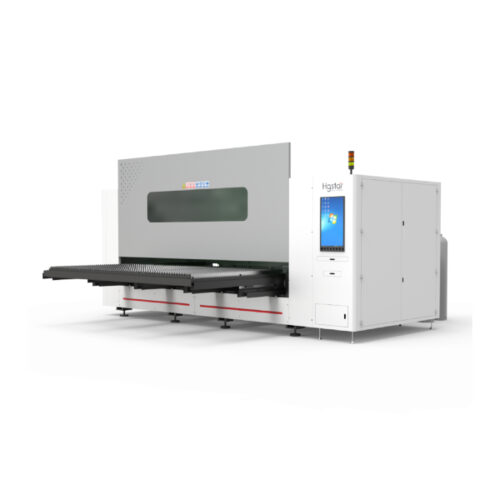

HG farley for processing station laser cutting equipment upgrade needs of customers, the launch of high-performance laser cutting products – MARVEL6000 CNC fiber laser cutting machine. With super high cost performance, mastering the core light source technology and low maintenance cost, it can solve the problem of high investment return ratio and equipment maintenance cost for growing customers.

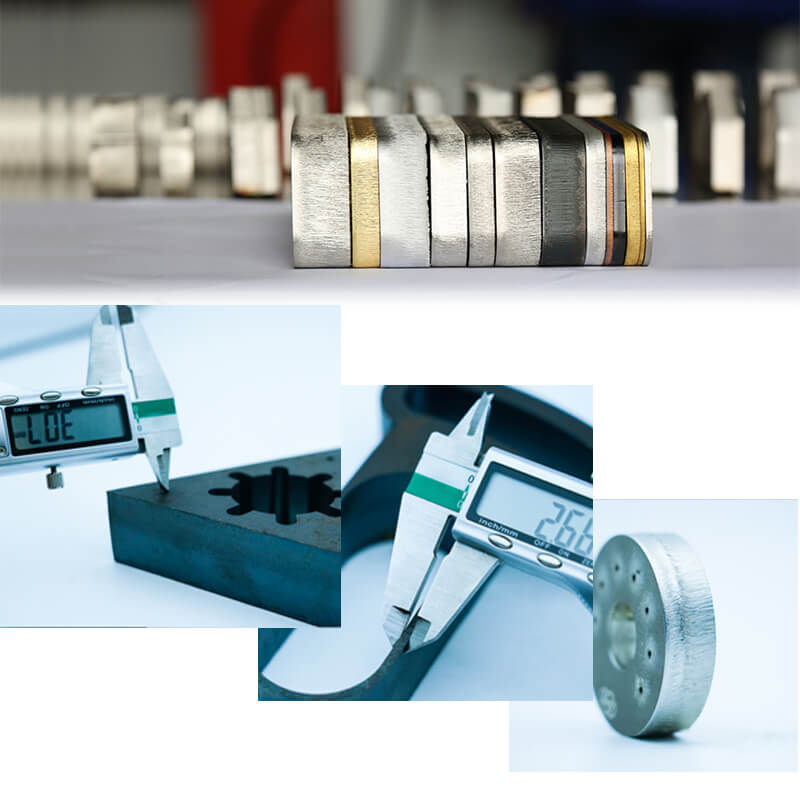

The most important feature of laser processing technology is that it can be processed without molds. The use of laser processing drop material eliminates the use of a large number of molds, which shortens the production time and reduces the cost of the product, which is better to gain advantages in the market and is conducive to the production of multiple types of small batch products and large batch products.

Customer benefits

High processing efficiency

Fast cutting speed, short product production cycle, fast forming cutting

Good cutting quality

Narrow cutting seam, smooth and beautiful cutting surface, no slag, no burr, high precision

High degree of automation

Automatic cutting and nesting can be realized, and the CNC system is easy to operate.

Lower production cost

No tooling, no tool wear, less material waste, lower labor costs