Projects

Technological Advantages of Laser Welding Machine In Ultra-thin Material

Stainless steel is a very common material in our life and production. With the continuous expansion of the stainless steel market, thin stainless steel is widely used in kitchenware, bathroom, small household appliances, doors and windows and other industries.

As the stainless steel plate goes deep into various fields of production and manufacturing, the welding process of thin stainless steel plate has become an important process in production and manufacturing.

In order to save costs and improve production efficiency, laser welding technology has been applied more and more widely in 3C industries and so on, and the lasers selected are also changing.

There is a big problem in processing thin stainless steel by traditional welding machine. Because of its small thermal conductivity and small degree of constraint, the thin stainless steel will form uneven stress and strain once it is locally heated and cooled during the welding process. The longitudinal contraction of the weld will produce a certain pressure on the outer edge of the stainless steel sheet. Once the pressure is too large, the traditional welding machine will cause wavy deformation of the workpiece, It will not only affect the beauty but also affect the quality of the workpiece. In addition, it will also have the problem of burning and burning through.

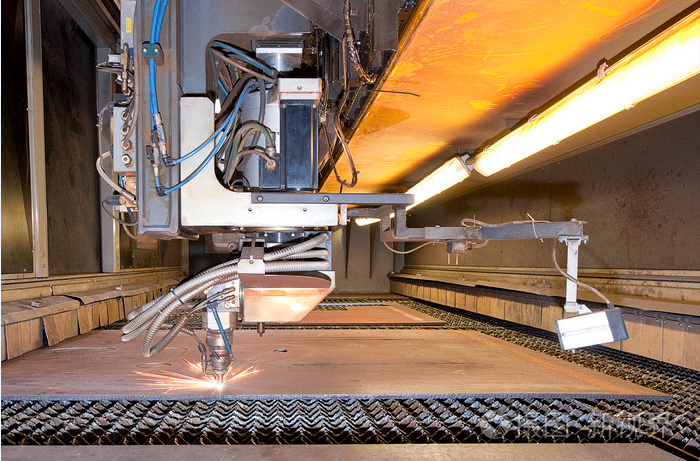

The appearance of optical fiber laser welding machine has solved this problem. Laser welding uses high-energy laser pulses to locally heat materials in a small range.

Compared with other welding machines, metal laser welding machine has the advantage of wide range of application. It can be widely used in the welding of stainless steel, metal, alloy and other same materials, and can also realize the welding of different materials; What are the technological advantages of laser welding machine in welding ultra-thin materials?

Technological advantages of laser welding machine in welding ultra-thin materials:

- Laser welding machine is easy to cooperate with computer numerical control system or manipulator and robot to realize automatic welding and improve production efficiency.

- Laser processing welding is non-contact processing, and there are no problems such as tool loss and tool replacement. The laser beam energy can be adjusted, the moving speed can be adjusted, and various welding processes can be carried out.

- Laser welding can be controlled by computer, with fast welding speed and high efficiency. It can be used to weld any complex shape conveniently.

- The welding process does not pollute the environment. It can be directly welded in the air, and the process is simple.

- The welding spot is small, the weld seam is narrow, neat and beautiful, and there is no need to deal with or just a simple process after welding.

- Because the beam is easy to transmit and control, and the welding torch and nozzle do not need to be replaced frequently, the auxiliary time of shutdown is significantly reduced, so the load factor and production efficiency are high.

- It is easy to realize automation and can effectively control the beam intensity and fine positioning.

The above is the technological advantage of laser welding machine in welding ultra-thin materials. The laser welding of ultra-thin plate materials adopts positive defocus. Under the same defocus amount, the weld surface obtained by positive defocus laser welding is smoother and more beautiful than that obtained by negative defocus. For laser welding of ultra-thin stainless steel materials, because the material is very thin, it is easy to vaporize and perforate. In order to obtain a continuous, non-burnthrough weld, the key is to accurately control the parameters.

About HGSTAR: HGSTAR is is a sub-brand of HGTECH.HGTECH the pioneer and leader of laser industrial application in China, and the authoritative provider of global laser processing solutions. We have comprehensively arranged laser intelligent machine, measurement and automation production lines, and smart factory construction to provide overall solutions for intelligent manufacturing.