Projects

The Trend of Laser Tube Cutting Machines In Global Market

A laser tube cutting machine operates by directing a high-energy laser beam onto the surface of metal pipes, causing rapid melting and vaporization of the metal to create a cutting groove. The laser beam moves along the pipe while interacting with a high-speed airflow to blow away the molten metal residues, ensuring the clarity of the cutting groove and ultimately completing the cutting process. Compared to traditional manual pipe cutting methods, laser tube cutting systems offer several advantages, including high cutting precision, efficiency, flexibility, automation, and the ability to achieve mass production. The cutting speed can reach several meters per minute, and the cutting precision can be as fine as about 0.1 millimeters, far surpassing traditional cutting methods. Moreover, this machine produces smooth and clean cuts without burrs or deformations, allowing for direct subsequent processing and assembly. Operating a laser tube cutting machine is straightforward and convenient, as it can be controlled through a computer to perform various complex cutting tasks with ease.

In recent years, with the acceleration of new infrastructure construction, heavy-duty pipes have found increasingly broad applications in fields such as aerospace, engineering machinery, and rail transportation. The cutting width of laser-cut pipes, including cutting lines, bevels, and shaped cuts, generally ranges from 0.1 to 0.3 millimeters. Laser cutting offers controllable cutting positions and temperatures, which are conducive to automation and intelligent production.

Compared to traditional processing methods, tube laser cutting can improve cutting efficiency by 8 to 20 times, reduce processing costs by 70% to 90%, and save material consumption by 15% to 30%. Laser cutting produces minimal noise and has a smaller environmental impact. Traditional processing methods require multiple consecutive steps to complete part fabrication, whereas laser cutting can achieve this on a single machine.

As equipment performance continues to improve and processing techniques are refined, the use of lasers for high-quality pipe cutting becomes increasingly feasible and efficient.

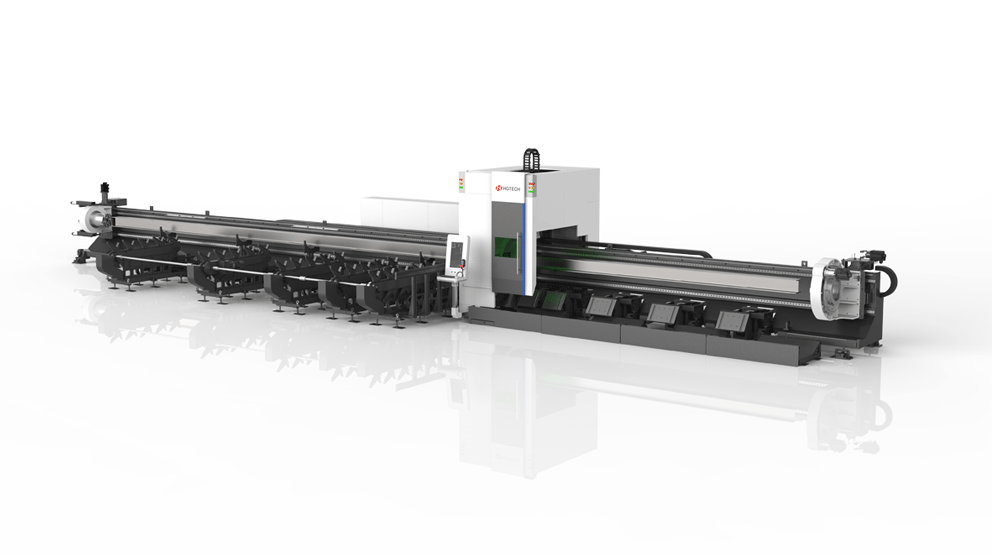

Laser tube cutting machines come in various types, including single-chuck, 2 chucks, 3 chucks, 4 chucks, manual, semi-automatic, and fully automatic models. Each type of laser tube cutting machine is designed with its own unique features. Currently, double-chuck laser tube cutting machines remain the mainstream product in the market. However, with technological advancements and increasing demands for high-quality pipe processing, the market demand for quadruple-chuck and fully automatic laser tube cutting machines is steadily growing.

With the advancement of domestic laser cutting technology, the huge market demand allows companies to see opportunities. Domestic laser cutting equipment has obvious advantages in after-sales service, price and cost. Since then, the door to domestic laser cutting equipment has been opened, and high-end machines are available at more favorable prices. Entered the market. In the past few years when laser cutting equipment has been booming, metal processing-related industries have also achieved strong growth, and efficient processing methods have become the first choice for more companies. In the context of China’s intelligent manufacturing, the industrial field is transforming from traditional processing to high-end manufacturing, and the market size of China’s laser cutting field will maintain a rapid development trend. In the future, the laser cutting machine industry will tend to be informatized, efficient and environmentally friendly. Therefore, it is necessary to strengthen the strategic positioning and guidance of the laser cutting machine industry, promote the large-scale development of enterprises, improve efficiency, informatization and intelligence, and better meet the needs of market development.