Projects

Tire Mold Laser Cleaning – Why It’s the Best Choice?

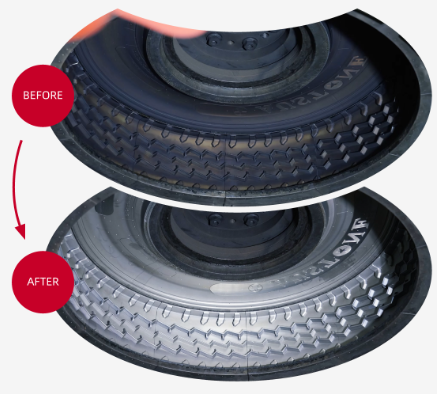

In recent years, with the increasing awareness of environmental protection, significant challenges have been posed to the global cleaning industry. Various environmentally friendly cleaning technologies have emerged in response, among which laser cleaning technology stands out. Laser cleaning technology utilizes high-energy laser beams to irradiate the surface of workpieces, causing instant evaporation or detachment of contaminants, rust spots, or coatings. This high-speed and effective process removes adherents or surface coatings from cleaning objects efficiently.

So why would laser cleaning be the best choice for tire mold cleaning compared with traditional methods?

In the production of automobile tires, the bottom and tread patterns of tire molds need to be cleaned every two to three weeks, with a thorough cleaning every few months. Traditional methods involve sandblasting or soaking in chemical solutions, which are not only costly and noisy but also environmentally harmful, affecting the surface quality of the molds. Moreover, these methods do not allow for online cleaning, requiring time-consuming disassembly before cleaning and reassembly after, which disrupts the smooth operation of the production line.

Using laser technology for mold cleaning enables online cleaning operations. Depending on the amount of organic contaminants on the mold surface and the structure of the rubber material, cleaning a set of molds only takes 45-90 minutes (including assembly, disassembly, and cleaning of parts on both sides of the mold). Since the mold surface can reflect the laser beam, there is no risk of damaging the mold surface with laser cleaning. Laser cleaning offers high flexibility, allowing users to completely replace other methods they are currently using.

Furthermore, each set of molds requires cleaning approximately every three weeks. If the system operates at full capacity, for instance, at a tire manufacturing plant cleaning 1500 pairs of molds per year, it could save 6000 hours of production time and increase tire output by about 30,000 sets. This not only benefits the environment but also yields considerable economic gains.

In conclusion, laser cleaning technology offers clear advantages: it is fast, reduces labor intensity, causes no wear, and poses no risks to operators.

And HGTECH’s Tire Mold Intelligent Laser Cleaning Equipment undoubtedly stands out as your best choice!

In addition to effectively solving pain points and challenges such as long standby times, frequent disassembly, mold wear, incomplete cleaning, environmental pollution, and high energy consumption associated with traditional cleaning methods, HGTECH’s Tire Mold Intelligent Laser Cleaning Equipment has developed independently several core components and processes including lasers, cleaning heads, and visual guidance technology. It can clean a pair of tire molds online in as little as 45 minutes.

Moreover, with the latest release of Version 2.0 Tire Mold Intelligent Online Laser Cleaning Equipment, it can clean a pair of tire molds in as fast as 30 minutes!

2.0 Tire Mold Intelligent Online Laser Cleaning Equipment

Furthermore, our equipment utilizes a 3D vision system to automatically identify mold types. The cleaning head autonomously aligns with the center of the mold, enabling robotic automatic cleaning. The electric transfer vehicle is equipped with laser radar for area detection and profile scanning, allowing it to navigate around obstacles. Smoke and dust generated during laser cleaning are collected and processed synchronously to protect the surrounding environment.

With meticulous consideration for every detail, HGTECH’s Tire Mold Intelligent Online Laser Cleaning Equipment is undoubtedly your best choice. HGTECH is also continuing to accelerate the transformation of the tire manufacturing industry from “traditional manufacturing” to “green intelligent manufacturing”.