Tube processing method With the rapid development of global manufacturing, tube processing technology has also ushered in revolutionary breakthroughs. Traditional cutting methods, such as grinding wheel cutting and lathe cutting, although to some extent meet market demand, have many limitations in efficiency, accuracy, and flexibility. The rise of laser cutting technology has brought unprecedented changes…

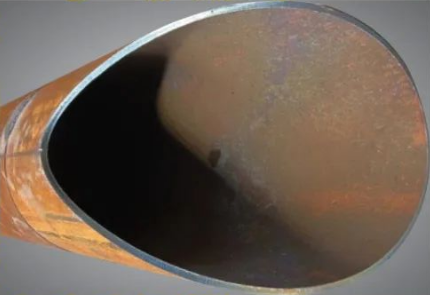

The importance of heavy-duty tubes In modern manufacturing, heavy-duty tubes have won the favor of many industries due to their excellent performance, wide application scenarios, and important role. From construction to industry, from machinery to bridges, heavy-duty tubes are everywhere, providing strong support and guarantee for various engineering projects. The processing technology of heavy-duty tubes…

Introduction Every giant ship is a pearl at sea, behind which lies the endless wisdom and sweat of the shipbuilding industry. Among them, the large groove laser cutting machine has injected new vitality into shipbuilding with its excellent performance and accuracy, becoming an important force in promoting the development of this industry. Ensure the stability…

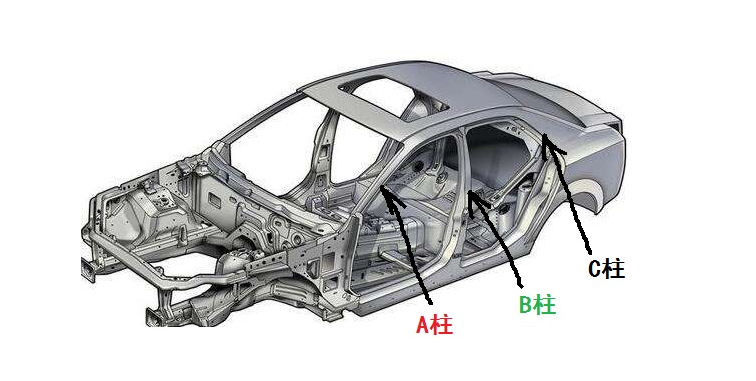

Introduction As a shining pearl of modern industrial civilization, the manufacturing process of automobiles gathers countless precision processes and cutting-edge technologies. Among them, groove processing is an indispensable part of welding technology, which directly affects the safety and stability of automotive structures. In this critical stage, the groove laser cutting machine has brought revolutionary changes…

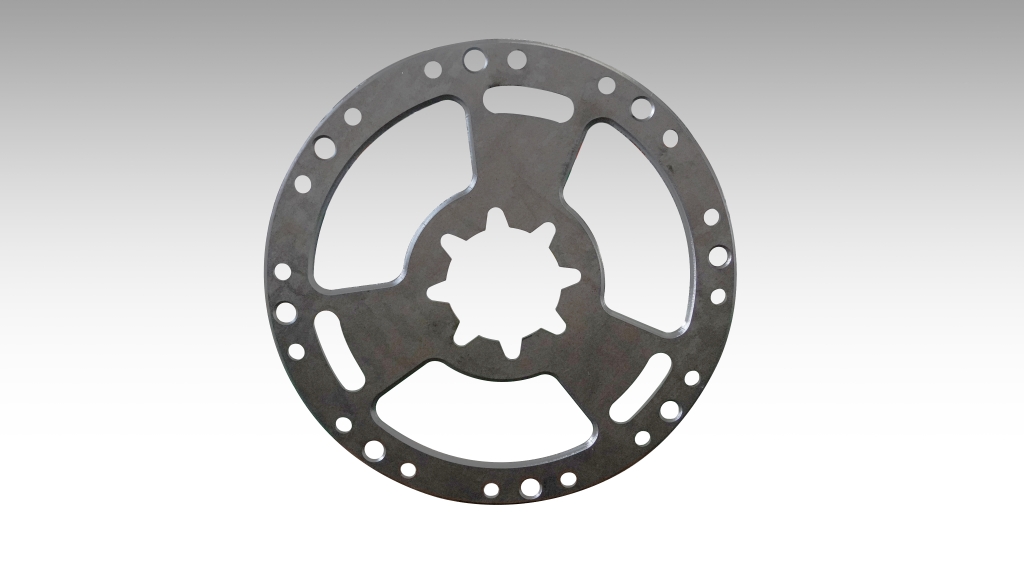

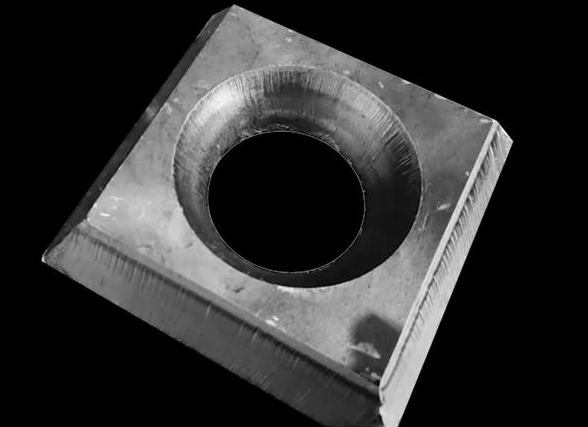

Widely used groove laser cutting Laser cutting technology has been widely used in the mechanical processing and manufacturing industry due to its high precision, high efficiency, and non-contact cutting characteristics. Especially in groove processing, laser cutting technology plays a crucial role. Below, we will use several practical cases to popularize the application of groove laser…

Introduction Laser cutting technology plays an important role in groove processing due to its high precision and efficiency. Below, we will provide a detailed introduction to the specific cutting techniques for different types of grooves. Detailed explanation of groove cutting process Firstly, let’s explore the cutting technology of V-shaped grooves. When processing V-shaped grooves, laser…

The development of large groove cutting machines In the hot cutting industry, in recent years, with the development of 5-axis linkage CNC technology, height adjustment technology, groove nesting technology, and rapid accuracy recovery technology, laser groove cutting has made breakthrough progress, and large-area laser groove cutting machines are gradually developing. The requirements for operators and…

From March 7th to March 9th, HGTECH will be attending ITIF Asia in Pakistan, one of the largest technology and information technology exhibitions in Asia. HGTECH will showcase its latest laser cutting and welding solutions at the booth, bringing innovation and efficient production tools to customers in Pakistan and the surrounding regions. Next, from March…

Difficulties in ship cutting The shipbuilding industry has high requirements for the accuracy of hull segmentation and transfer, and the clearance of frame transfer must be controlled within a range of 1mm. In the past, shipbuilding enterprises generally used plasma to cut the rib plates. In order to ensure assembly clearance, repair allowances were set…

Laser changes shipbuilding technology With the rapid development of technology, laser fiber optic metal cutting technology has become a powerful assistant in the modern shipbuilding industry. Among them, the three-dimensional five axis laser cutting machine is gradually changing the traditional method of cutting ship steel plates with its high-precision and high-efficiency characteristics. Combined with advanced…