The emergence and application of automotive hot forming technology have changed market demand. A car hot forming production line is generally equipped with 4-5 three-dimensional five axis laser cutting machines, and the market demand is developing explosively. As of now, there are nearly 450 automotive hot forming production lines worldwide, and there are approximately 2000…

The 3D five axis laser cutting machine is a high-precision CNC cutting equipment, and its excellent performance stems from its advanced technology. The following will introduce these technologies from five aspects. Firstly, the equipment adopts advanced laser technology. Laser cutting technology has higher accuracy, faster cutting speed, and smaller heat affected area compared to traditional…

3D five axis laser cutting equipment, as a laser processing equipment for cutting complex curved 3D parts, is a very effective processing method for high-strength steel structural components with complex contours, whether from a technical or economic perspective. Currently, it has been widely used globally, and the market demand is increasing. 1.Industry Opportunities and Drivers…

Although laser cleaning technology has become more mature after years of development, there are still some problems that need to be solved urgently due to the complexity of laser cleaning equipment. Hazards To Human Health In general, most lasers used for laser cleaning have higher power, and this technology will inevitably develop towards higher power…

Laser cleaning technology has many advantages that traditional cleaning methods can not reach, in order to ensure the cleaning effect, you can choose different wavelengths of laser according to the difference in laser absorption rate of the cleaned object at different wavelengths. Demand Of New Laser Cleaning Technology However, for the cleaning of…

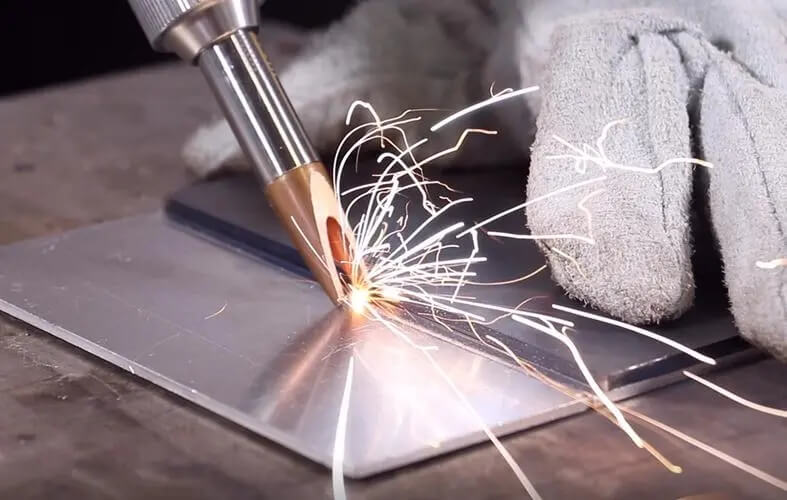

In recent years, laser handheld welding has become a dark horse in the field of laser applications, with an annual compound growth rate of over 100%. At the recent Essen Welding Exhibition, laser companies’ handheld welding products bloomed, and many companies engaged in traditional welding also began to enter the field of laser handheld welding….

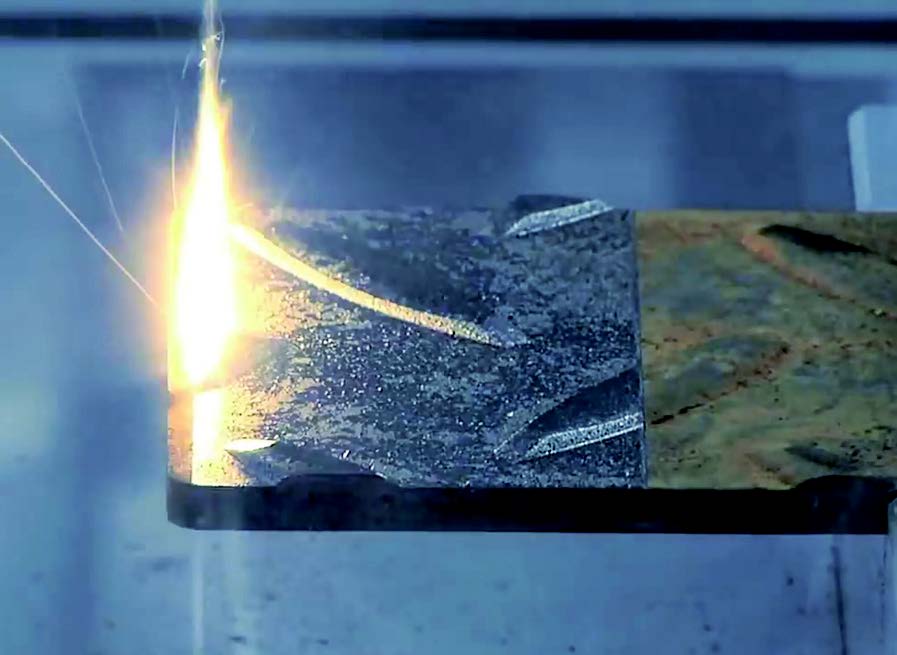

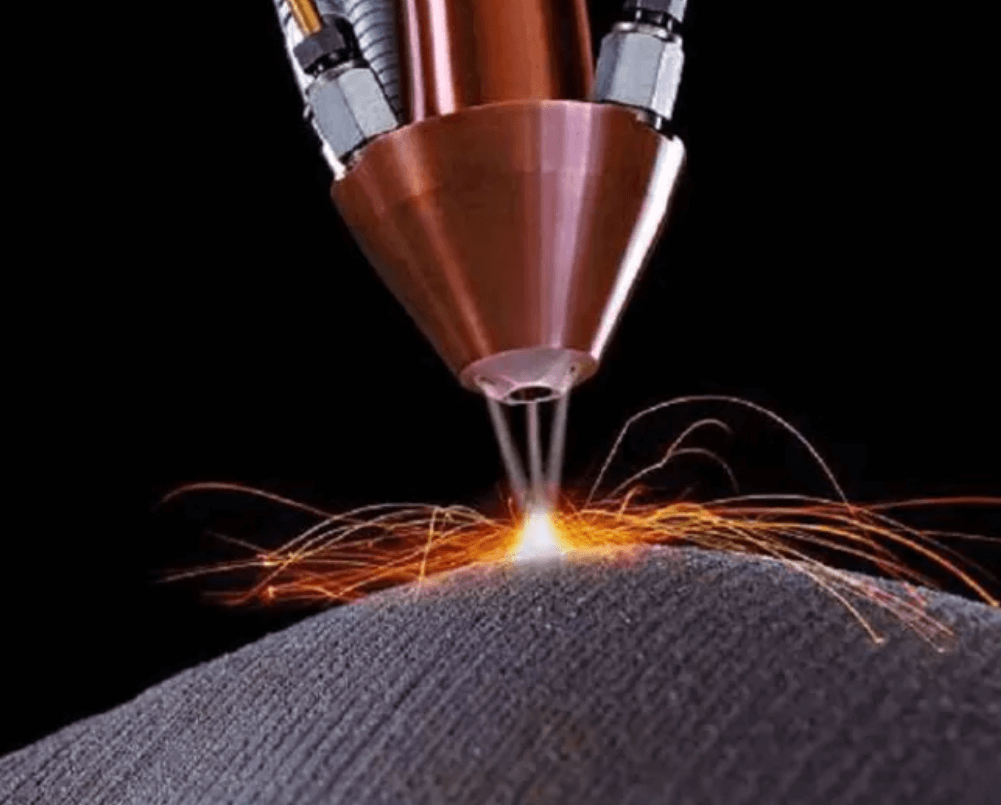

Laser cladding is a manufacturing technology that has received much attention in recent years. It not only has various advantages and advantages in application, but also is the first thing that many people think of when mentioning related fields. So, what exactly is this technology? What are its applications? Let’s take a look together. Laser…

According to the report of Nikkei Sangyo Shimbun on July 10, Tokyo Institute of Technology and other institutions are vigorously developing the “optical wireless charging” technology based on laser. By shining a laser on an object, light energy can be converted into electrical energy. This not only saves the trouble of configuring charging cables for…

As a new type of clean energy, lithium batteries are widely used. Laser technology, as an advanced “light” manufacturing tool, is widely used in the cutting, cleaning, welding, and coding processes of power lithium battery components due to its high efficiency, precision, flexibility, reliability, stability, low welding material loss, high automation and safety. Let’s take…

Under the active promotion of leading enterprises in industries such as Hisense, Changhong, Guangfeng, and Zhongke Aurora, China’s laser display technology and industry have developed rapidly, and the industrial chain has been rapidly improved. At the same time, in terms of overall machine manufacturing, Chinese enterprises have also explored mature technology and experience, and are…