Projects

Laser Blanking Becomes The First Choice for Automotive Industry Processing

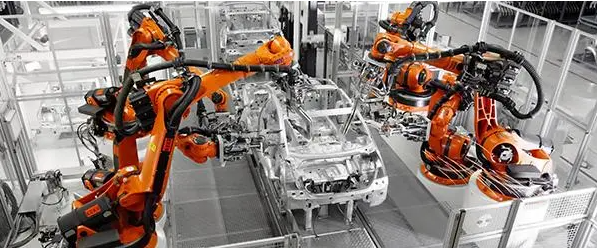

In the automotive industry, where advanced technologies are most concentrated, lasers are reflecting their growing presence with bright light.

Taking automotive panel processing as an example, the laser blanking line is one of the most widely used and popular processing methods at the moment. Why does laser blanking attract so much attention and become the first choice in the automotive industry?

The highly flexible coil fed laser blanking line can produce sheets without the need for molds. For the production needs of sheet materials of different shapes, quick switching can be achieved by just pressing the button. Compared with traditional molds, laser blanking lines can save the time of replacing molds and the cost of mold storage and maintenance. Calculated at 12 molds per model, the coil fed laser blanking line can reduce the production cost of new models by millions of dollars.

Take the most popular aluminum alloy plate nowadays as an example. The surface of aluminum alloy is very sensitive, and aluminum chips and surface scratches are easily generated during processing.

The high precision and intelligence of the laser blanking line can ensure that there are no burrs or aluminum chips during the processing of aluminum alloys, and at the same time ensure the high quality of the surface of the blank.

For the high-strength steel used in the automotive industry, which continues to increase in proportion, the laser blanking line can easily cope with various processing requirements.

The coil fed laser blanking line has high flexibility in adjusting the sheet parameters .

Laser cutting procedures can be flexibly customized and modified according to needs, while mold-free small batch production is possible.

During mass production, the laser uncoiling and blanking line can also easily modify the parameters of the blank and replace with new materials.

Customers can install a coil fed laser blanking line in their own factory for flexible small-batch production, or they can process at a supplier with a coil fed laser blanking line, or directly purchase blanks.

This can not only complete the production task in a shorter time, but also save the uncoiling and shearing process.

Therefore, the laser uncoiling and blanking line has great advantages in material saving, cost saving and flexible purchasing strategy.