In this era of rapidly evolving AI and laser technology, we had a sudden thought: If we asked different AIs about HGTECH, how would they describe this leading company in China’s laser industry? So, we posed the question to both ChatGPT and DeepSeek—and the results were truly eye-opening… Each AI responded in its…

Current Industry Challenges and Marking Limitations In industries such as manufacturing, electronics, automotive, and healthcare, QR codes have become essential tools for product traceability, anti-counterfeiting, and supply chain management. However, traditional marking methods like inkjet printing, etching, and labeling often face issues such as insufficient durability, wear and tear, and poor adhesion, making them unreliable…

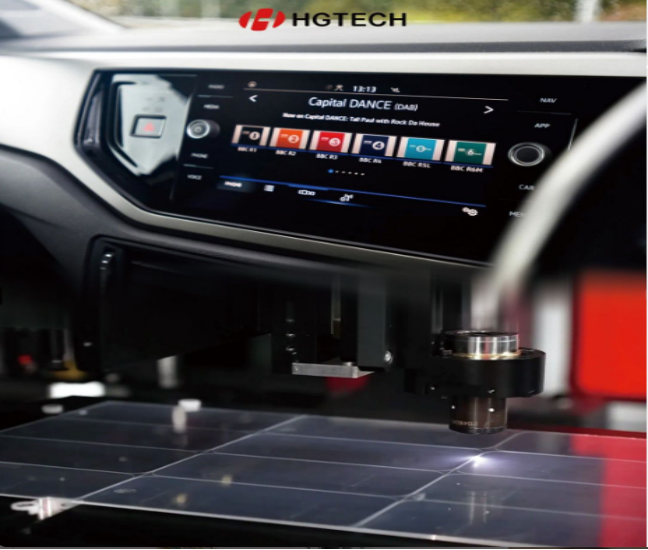

Efficient laser processing With the development of automotive intelligence, in-car central control screens have become an essential component for enhancing the driving experience. Whether for traditional gasoline-powered vehicles or new energy vehicles, an increasing number of models are equipped with larger, higher-resolution screens, including curved and custom-shaped displays, to meet the demands of driver assistance,…

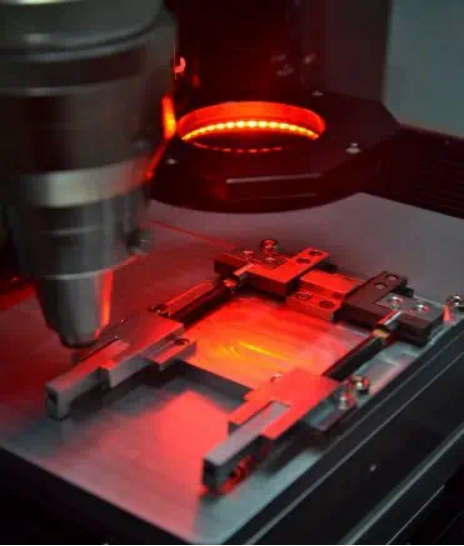

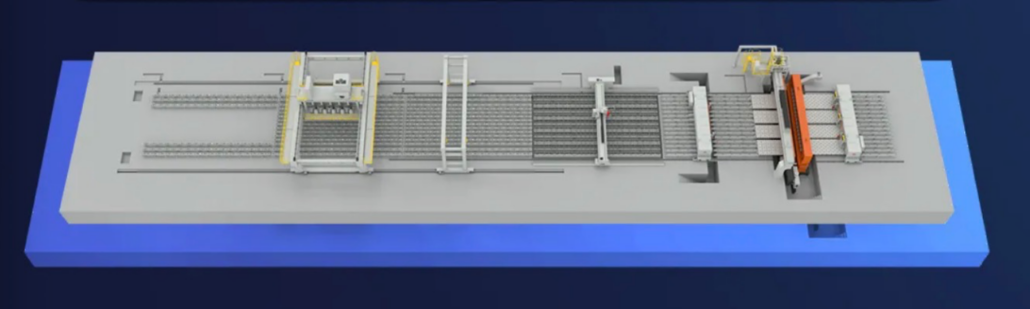

Current Industry Landscape: The Rise of Laser Processing With the accelerating global electrification trend, industries such as new energy vehicles (NEVs), high-efficiency motors, and smart grids are driving an increasing demand for silicon steel sheets. As a core material for motors and transformers, the processing precision of silicon steel sheets directly impacts the energy…

As consumer demands for food safety and quality continue to rise, the food packaging industry faces stricter regulations and market requirements. Traditional packaging marking technologies, such as hot stamping and ink printing, have gradually exposed some issues, such as wearability, pollution, and unclear printing. Especially in the food sector, the information on packaging needs to…

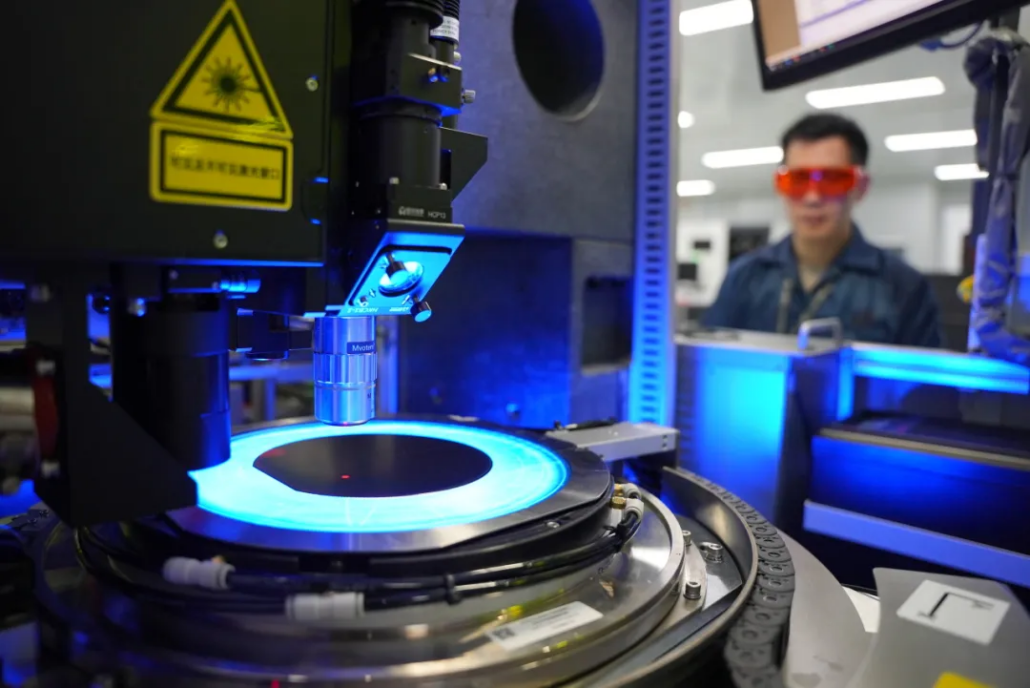

During high-speed wafer cutting, a large amount of dust particles is often generated. These fine particles can settle on the wafer surface during processing, causing scratches on the dies, which in turn leads to a decline in wafer yield and increased manufacturing costs. As a crucial process in semiconductor assembly and testing, wafer cutting…

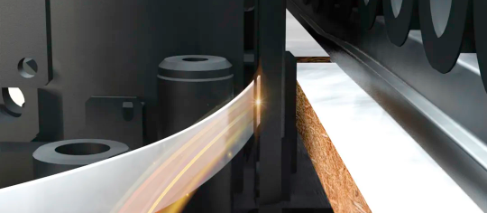

The furniture industry is currently evolving in four directions: refinement, scalability, branding, and technological innovation. Laser edge banding technology, as the latest seamless edge banding technology, typically uses an edge banding tape with a functional layer of only 0.1 to 0.2 mm in thickness. It compensates for the shortcomings of traditional EVA/PUR hot-melt…

Recently, the “Laser Precision Heating Bottle Preform Intelligent Equipment” independently developed by HGTECH successfully passed the bottle-blowing test in Hangzhou, achieving a domestic first in this field. With the green and low-carbon transformation of the manufacturing industry, the traditional PET preform production industry is facing dual challenges: technological advancement and environmental compliance requirements. …

Tire molds are easily affected by rubber particles, additives, release agents, and other substances during the production process, which can negatively impact tire quality and lifespan. Therefore, regular cleaning of the molds is essential. Traditional cleaning methods, such as dry ice cleaning, though commonly used, have issues like storage difficulties, poor working conditions, and low…

Currently, the global shipbuilding industry is experiencing a new growth cycle, showcasing unprecedented development opportunities. Welding automation, as one of the key technologies in shipbuilding, accounts for approximately 30% of the total shipbuilding cost, yet its automation rate is only 5%. There is an urgent need for the adoption of efficient and reliable automated…