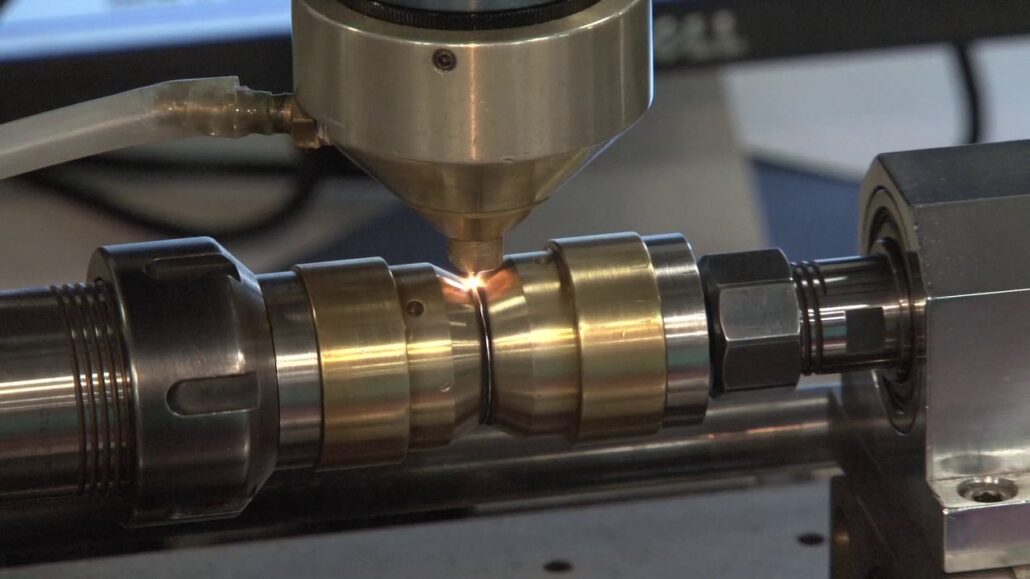

The tube cutting machine is a specialized piece of equipment used for cutting pipes, typically employed in industries such as construction, manufacturing, aerospace, and more. Compared to traditional cutting methods, laser tube cutting machines offer higher precision and efficiency. The cutting principle of a laser tube cutting machine is not significantly different from that of…

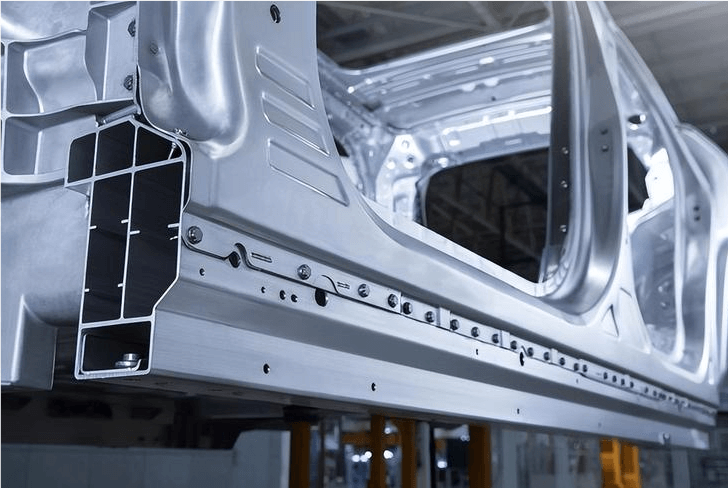

The development of automotive lightweighting has made energy efficiency, environmental friendliness, and safety essential considerations in the automotive design and production process. High-strength hot stamping of steel plates can reduce fuel consumption and improve passenger comfort while ensuring automotive safety performance. Currently, it is mainly used to manufacture important structural components such as B-pillars, A-pillars,…

The automobile industry is a production-oriented industry that requires a lot of processing and testing. It is also one of the industries where laser technology is most widely used. Safety, comfort, energy saving and environmental protection have always been the themes of the development of the world’s automobile industry. Laser technology is an important part…

For automobiles, besides fuel efficiency, a lightweight all-aluminum alloy body can presents ultimate power and handling performance. Generally, with constant power output, lighter vehicles accelerate faster, offer a more sporty driving experience, and exhibit reduced body roll during cornering. Moreover, under equivalent strength conditions, lighter cars are safer. Heavier vehicles possess greater inertia, leading to…

In the realm of automobile manufacturing, a significant application of laser welding lies in the welding of automobile BIW (body-in-white). One prime example of this is the welding of the automobile roof panel to the side body panel. Laser welding reduces the overlap width between the roof panel and the side body, thereby decreasing the…

“Sci-tech self-reliance and self-strengthening form the foundation of national prosperity and the essence of security”, remarked Xi Jinping, President of the People’s Republic of China, during a significant address delivered while visiting Wuhan, Hubei Province. This statement generated enthusiastic responses among faculty and students at universities. During his visit to HGTECH, President Xi emphasized that…

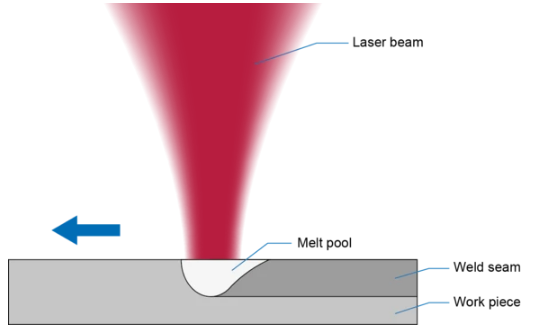

3. Porosity Porosity is a common defect in the laser fusion welding process, and its causes include the following: Instability in the shape and volume of the weld pool during laser fusion welding, resulting in the continuous formation and closure of small holes in the base material. Inadequate escape time for zinc vapor from the…

In the realm of automotive manufacturing, technological innovations are steering the industry toward higher precision, efficiency, and safety. One of the standout technologies revolutionizing the sector is laser technology. From cutting-edge applications in the production of hot-formed components to groundbreaking advancements like HGTECH‘s 3D 5-axis laser cutting machine, lasers are reshaping the landscape of automobile…

During the process of laser fusion welding, various factors such as laser beam agitation of the weld pool, evaporation of alloying elements in the base material, temperature gradient of the weld pool, and metal vapor will all impact the quality of the welding. The following is a detailed analysis of defects in laser fusion welding….

Laser welding has become a standard process in the automotive industry. In the context of automobile body assembly production lines, the utilization of five-axis laser processing machines or laser processing systems with optical fiber transmission has been extensively employed for the welding of car body components. The three major American automotive conglomerates (General Motors, Ford,…