Factor 3: Weld Seam Arrangement In modern automotive body welding, laser welding has been widely adopted to replace traditional resistance spot welding. This shift aims to reduce costs, enhance production efficiency, significantly improve impact resistance and fatigue resistance of the vehicle body, and consequently elevate overall automobile quality. Laser welding, characterized by rapid energy release,…

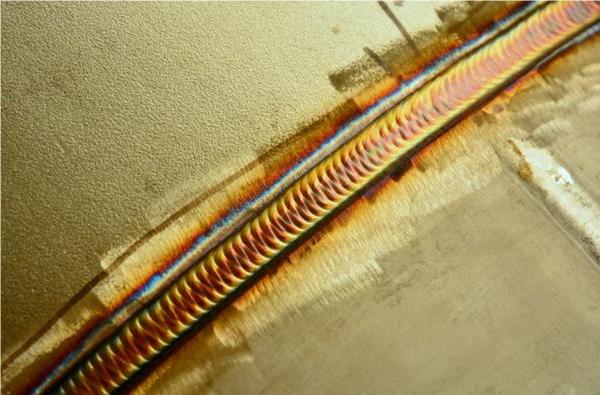

Factor2: Overlap Joint Gap Between Two Panels During the stamping process of vehicle body components, springback deformation is prone to occur, resulting in a certain gap between the overlapping joints of the two components even under a specific clamping force. Due to the impact of zinc vaporization in galvanized steel plates used for the vehicle…

As a highly advanced welding technique, laser welding is generally preferred for application in parts where stringent welding quality is required. In such parts, if spot welding is chosen, the limited welding space would lead to intricate process arrangements, resulting in subpar welding quality and an inability to achieve the desired visual quality effects in…

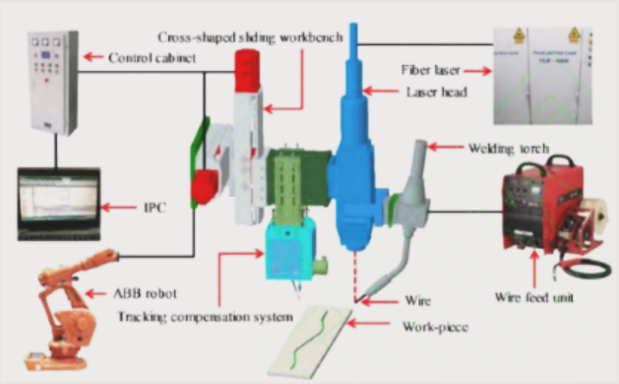

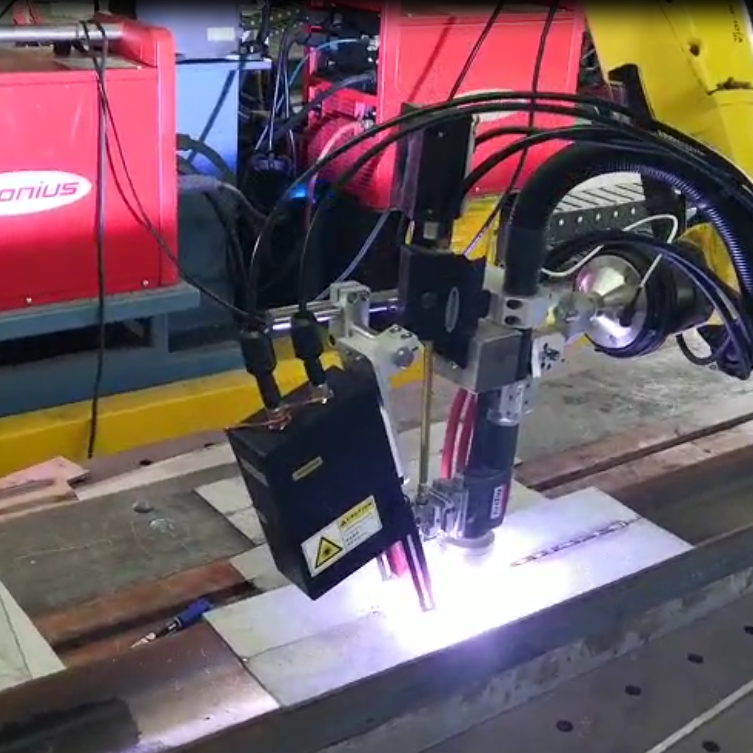

The laser welding process for automotive body structures demands a high level of seam recognition and localization. Swift and accurate identification and positioning of seams are essential technical means to ensure an intelligent welding process. Seam tracking during the automotive body laser welding process relies on real-time sensing by sensors on the workpiece, determining seam…

In the backdrop of the new wave of technological revolution, the automobile industry is progressively transitioning towards electrification, intelligence, and sharing. This global automotive paradigm shift marks an unprecedented transformation of the industry in a century, ushering in significant novel opportunities for both upstream and downstream sectors within the automotive supply chain. Regardless of whether…

Since the development of roof panel laser welding technology by Volvo in the early 1990s, a wave of innovation in body-in-white (BIW) welding technology has swept through the global automotive manufacturing sector. Major automotive manufacturing companies around the world have vigorously pursued the development and application of various advanced welding techniques, greatly enhancing production efficiency…

Technology and application development trend Trend of Technology As three-dimensional five-axis laser cutting technology advances, its capabilities are growing more powerful. The trends in technological development are outlined below: (1) High acceleration and high speed. The acceleration of cutters continues to increase, resulting in higher speeds and improved production efficiency; (2) High cutting speed and…

Research on integrated application technology of 3D five-axis fiber optic cutting system with RTCP function (1) Research the hardware integration system structure of three-dimensional five-axis fiber laser cutting equipment, analyze the software and hardware interface of the numerical control system with RTCP function, and design the system integration control scheme of each processing component in…

Current status of technological development At present, the main manufacturers of 3D five axis laser cutting machines include Trumpf in Germany, Prima in Italy, NTC in Japan, Mitsubishi in Japan, and Huagong Laser in China. Trumpf and Prima are highly recognized by market customers due to their early production, mature products, stable performance, and high…

The three-dimensional five axis fiber laser cutting machine is regarded as the pearl on the crown of high-power laser processing equipment. It is mainly used for cutting holes and trimming three-dimensional irregular surfaces, replacing punching and trimming dies. In the early days, manual plasma cutting of three-dimensional workpieces was used in China, but the cutting…