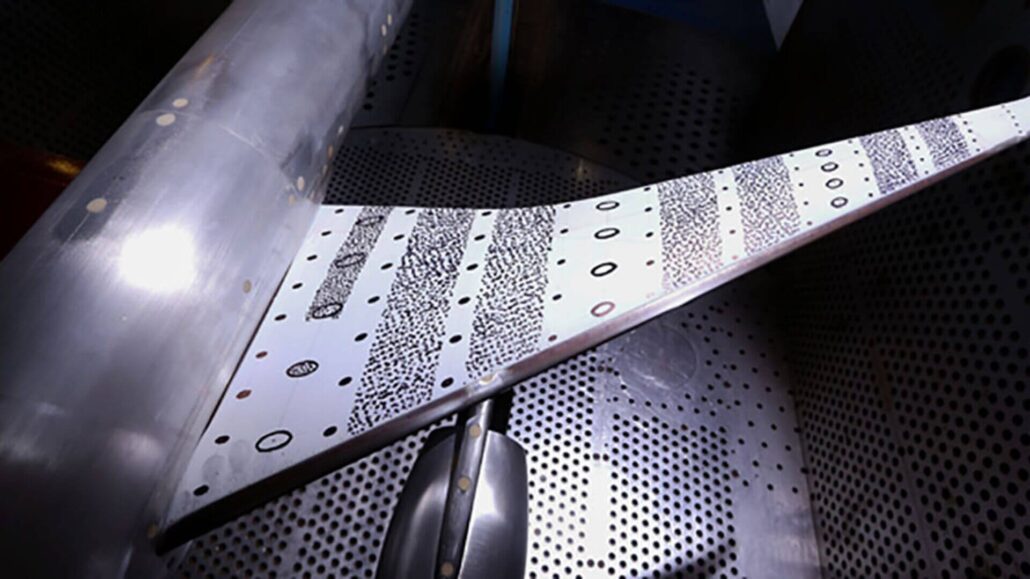

Stainless steel railbus has the advantages of light weight, good corrosion resistance, simple manufacturing process, low maintenance workload, good safety performance, and is conducive to environmental protection, etc. Therefore, the development of stainless steel railbus has become an important development strategy for the rail transit industry in Europe, America, Japan and other industrially developed countries….

Drawbacks of Traditional Sandblasting Cleaning In ship manufacturing and repair, cleaning, as a necessary process, is mainly used in the two stages of steel plate pre-treatment and segmented pre-treatment for newly built ships, as well as rust removal and paint removal during ship repair. At present, sandblasting method is mainly used for ship pre-production cleaning….

The automotive industry is one of the largest applications of laser material processing. According to data from McKinsey’s Future Mobility Center, the automotive sector accounted for approximately 7% of the EU’s GDP in 2019. At present, the supply chain restrictions caused by the COVID-19 epidemic have not been completely lifted, and the automobile production has…

Manufacturers in the aerospace industry use laser cleaning to remove layers from metal and composite surfaces in preparation for processing, remove coatings or corrosion, and remove paint from large components or entire aircraft before repainting. High Laser Cleaning Efficiency During the cleaning process, the laser is absorbed and evaporated by the metal surface, thereby achieving…

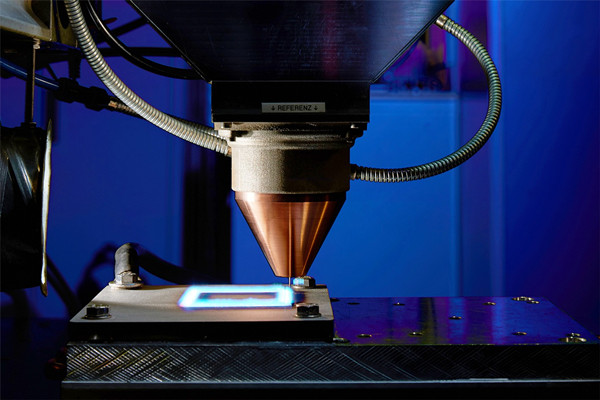

Laser processing plays a key role in the aerospace field The ability of laser processing to improve productivity and maintain low costs may play a crucial role in achieving this response in the aerospace industry. Laser processing – operations achieved through cutting, welding, shot peening, and drilling have become an indispensable part of aerospace manufacturing….

Motor Vehicles are Being Electrified In recent years, with the enhancement of environmental awareness and the improvement of technological level, the automotive manufacturing industry is facing tremendous changes and challenges. In this context, electrification has become one of the most important development trends in the automotive manufacturing industry. Laser Processing Has a Wide Range of…

Laser relief is a sculpture based on the surface of a material, using a laser beam as a “cutting tool” to cut or burn the material, forming a concave and convex three-dimensional image and text process. This article will be based on equipment application requirements such as reducing machine costs, high efficiency, and high precision,…

Nowadays, the problem of insufficient productivity caused by aging population and labor shortage has intensified, promoting the widespread and in-depth application of highly automated laser equipment products in the industrial field. According to data from Wuhan Literature and Information Center, the market size of laser equipment used in the industrial field in China accounted for…

The emergence and application of automotive hot forming technology have changed market demand. A car hot forming production line is generally equipped with 4-5 three-dimensional five axis laser cutting machines, and the market demand is developing explosively. As of now, there are nearly 450 automotive hot forming production lines worldwide, and there are approximately 2000…

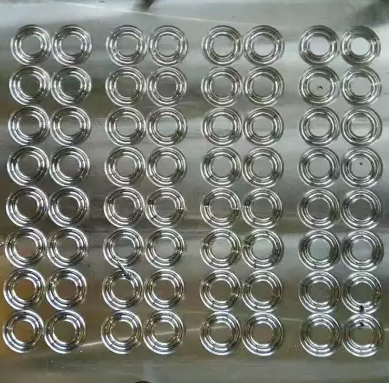

Laser cleaning of seal molds has good results and high efficiency, and can be done by hand or automated cleaning. With the continuous development of industrial technology, the methods of cleaning seal molds are also constantly updated and improved. In traditional cleaning methods, using chemicals and mechanical equipment to clean is time-consuming and labor-intensive, and…