Are you looking to DIY or purchase a low-cost metal laser cutter for stainless steel, carbon steel, tool steel, galvanized steel, spring steel, aluminum, copper, brass, alloy, silver, gold, iron, titanium, chromium, manganese, cobalt, nickel, lead, and other metal fabrication in the United States, United Kingdom, United Arab Emirates, Canada, Australia, Russia, South Africa, China,…

1000W Fiber Laser Cutting Machine for Metal Signs Carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper, and other metal materials are commonly cut with a 1000W fiber laser cutting machine. Sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components,…

The handheld fiber laser welding machine emits a pulsed laser with a wavelength of 1064nm after beam expansion, reflection, and focus to radiate the surface of the workpiece. Heat conduction transports surface heat to the interior, and digitalization precisely controls the width, energy, and peak power of the laser pulse. The workpiece is melted to…

Fitness equipment is a product that people who pursue fashion and love life often come into contact with. In recent years, the fitness equipment industry has become more and more demanding as the demand for Significant increase in demand for aerobic, strength equipment two categories of products, user experience standards are increasingly high, gym investors…

Since 2000, driven by the favorable situation of sustained national macroeconomic development, the automobile industry has entered a period of rapid development. The rapid development of the auto industry has significantly increased China’s position in the international auto market and has begun to become an important part of the world auto industry. Automotive industry solutions.jpg…

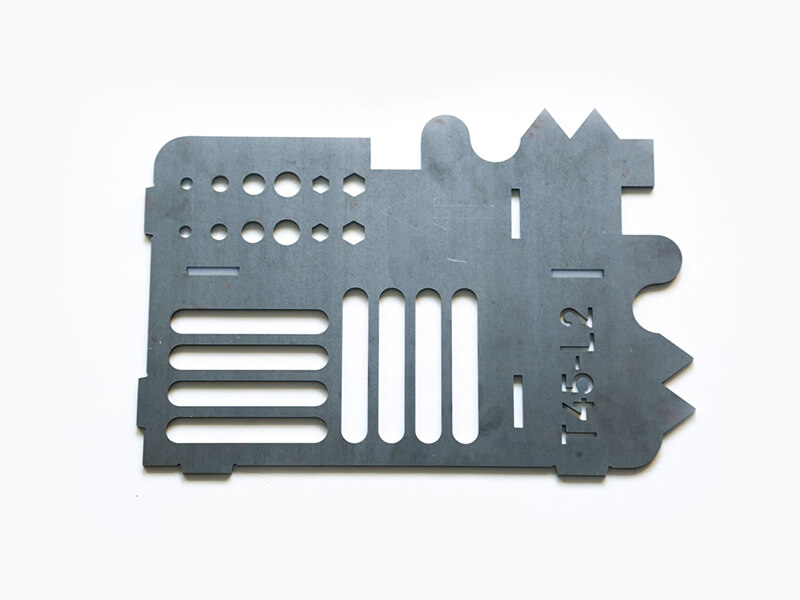

China is gradually becoming an international processing and manufacturing center, and the demand for metal processing is increasing, while electrical control boxes and machine housings in the metal processing industry are generally sheet metal parts, so the demand for sheet metal processing capacity is also increasing. Therefore, the demand for sheet metal processing capacity is…

Common Problems for the Laser Cutting stainless steel: (The amount of defocus is adjusted based on the thickness of the plate) 1: The higher the focus is, the brighter the cutting surface is. The focus is too high, the speed is too slow, and the air pressure is too low, resulting in hard slag hanging…

In the 1970s, lasers were first used for cutting. laser cutting machine is more commonly used in modern industrial production lines for sheet metal, plastics, glass, ceramics, semiconductors, textiles, wood and paper, and other materials processing. The use of laser cutting in precision machining and micro-machining will also see significant growth in the coming years….

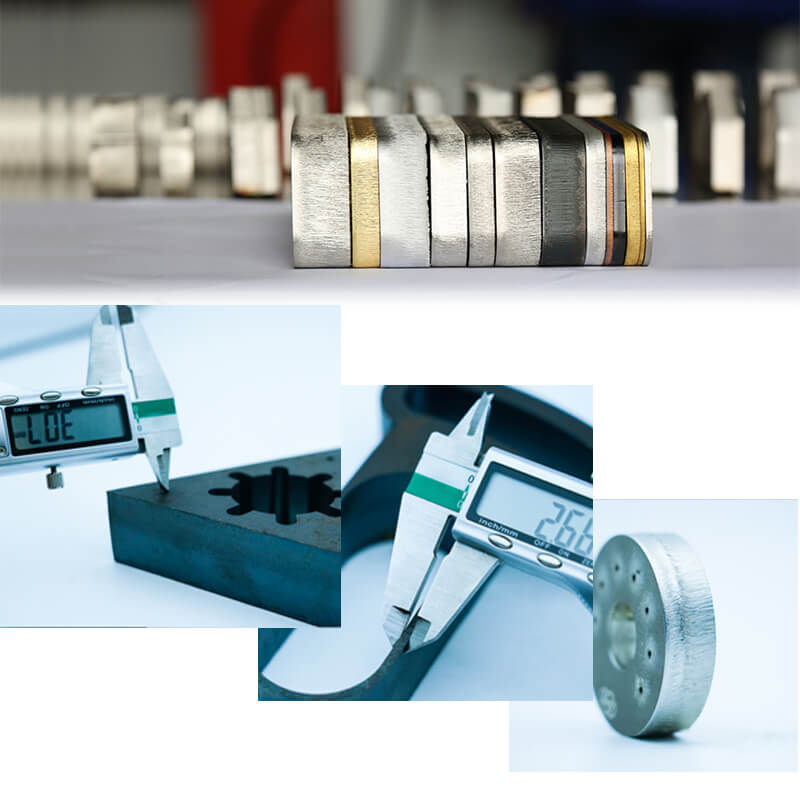

1.Standards for the advantages and disadvantages of laser cutting thick plates 1. Ruggedness The vertical lines formed by the laser cutting section determine the roughness of the cut surface; the shallower the lines, the smoother the cut section; the deeper the lines, the rougher the section. The higher the cutting quality, the shallower the grain….

.jpg)

.jpg)

.jpg)