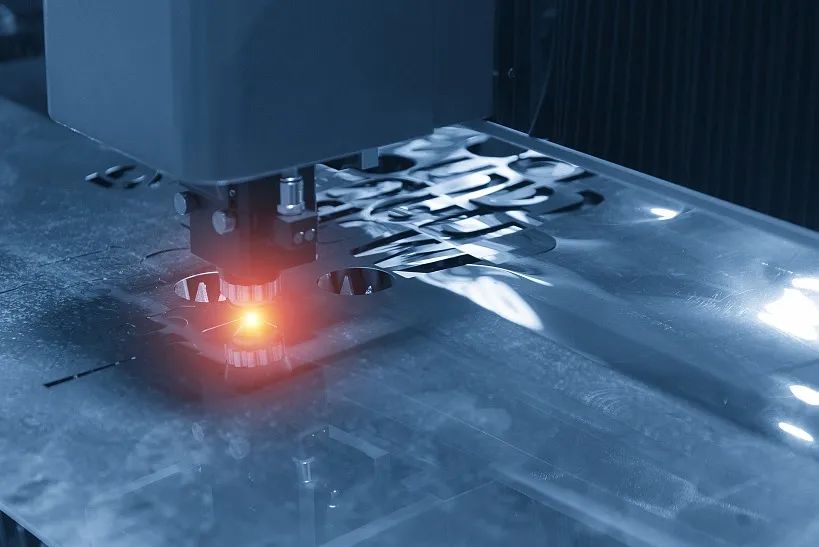

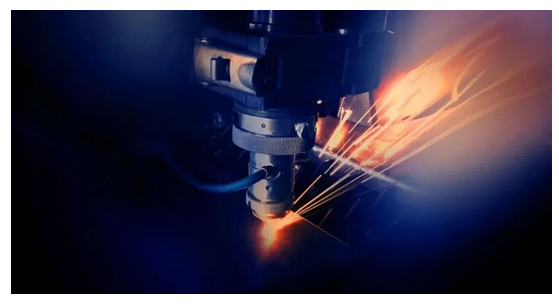

Introduction The laser cutting technology of the industrial laser cutter is to use the focused high power density laser beam to irradiate the workpiece, so that the irradiated material quickly melts, vaporizes, ablates or reaches the ignition point, and at the same time, the high-speed air flow with the beam coaxial blows away the molten…

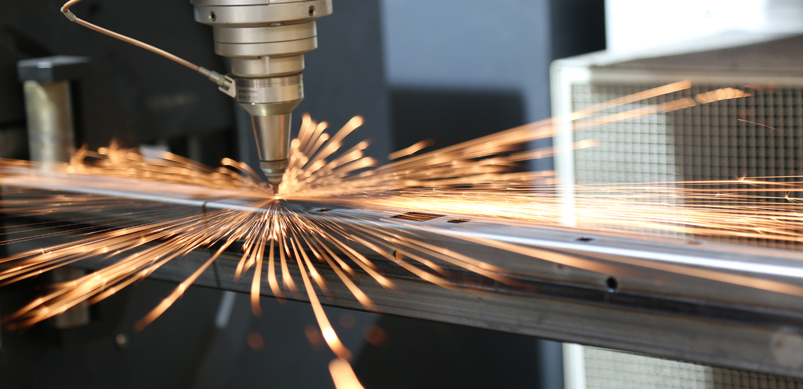

Introduction The main application of industrial laser cutter in the construction machinery industry is plate processing, generally using CO2 industrial laser cutting machine or fiber industrial laser cutting machine. Cutting applications mainly include slender workpieces, plate parts with more holes, sheet metal parts reservation process gaps, sheet metal templates and drilling samples. Six significant advantages…

Preface Laser cutting machines play a significant role in the industrial field, and laser cutting equipment has developed rapidly in recent years, widely used in sheet metal, hardware products, steel structures, and precision machinery industries. The characteristics of industrial laser cutter Firstly, industrial laser cutting machines have smaller cutting seams, resulting in less deformation of…

Preface With the continuous development of technology, laser cutting technology has become one of the popular technologies in the field of industrial manufacturing. Industrial laser cutter have the characteristics of high precision, high efficiency, and high quality. Laser cutting machine manufacturers provide new cutting solutions for industrial manufacturing. Advantages of laser cutting machine manufacturers 1….

Preface In recent years, thanks to the rapid development of the new energy industry, laser welding has rapidly penetrated the entire new energy industry due to its fast and stable advantages. Among them, the application proportion of laser welding equipment is the highest in the entire new energy industry. Laser welding has quickly become the…

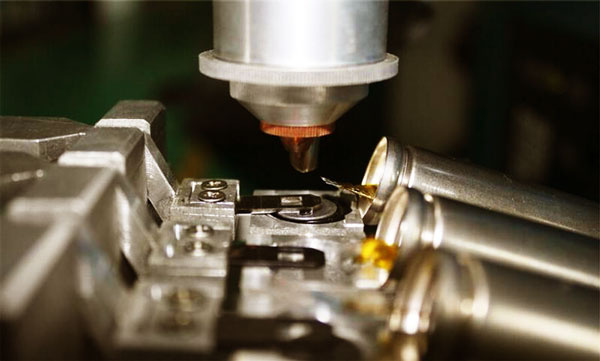

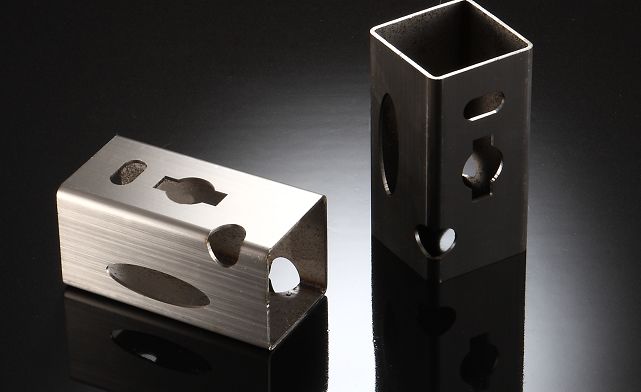

Why can laser tube cutting machines be applied in the specialized equipment manufacturing industry Tube laser cutting machine is a high-precision and high-efficiency metal processing equipment that uses a laser beam as a cutting tool to cut metal tubes according to predetermined sizes and shapes. This device is widely used not only in industries such…

Preface The laser tube cutting machine has become the preferred product in the equipment tube processing industry due to its progressiveness features such as easy operation, high automation, high-speed and high-precision cutting, and adaptation to the needs of mass industrial production. Mainly used in the following industries. Application in the construction industry The construction industry…

Laser tube cutting machine helps industrial development In recent years, with the rapid growth of the economy and the rapid development of industrial manufacturing, there has been a high demand for raw materials. Heavy metal tubes are in high demand in large-scale industries, and the development of industry has also driven the use of heavy…

Laser technology can solve the process problems in the energy storage industry With the rapid development of modern industry, the energy storage industry, as an important basic industry, is also growing rapidly. Laser technology has been widely applied to address some issues in the energy storage industry, such as laser tube cutting machines. This article…

Application of CNC laser tube cutting machine in the industry Laser tube cutting machine is a specialized machine tool for laser cutting of tube fittings and profiles, and is the preferred equipment in the non-contact metal tube processing industry. Mainly used for cutting metal tubes such as carbon steel tubes, stainless steel tubes, aluminum alloy…