As the Industrial Revolution brought unprecedented social and economic changes, the Industrial revolution in laser cutting in manufacturing is set to have a similarly transformative impact. Continued development and innovation in laser tube cutting technology will open up new possibilities for customization, efficiency and design freedom in manufacturing. Manufacturers that embrace this revolution will gain a competitive…

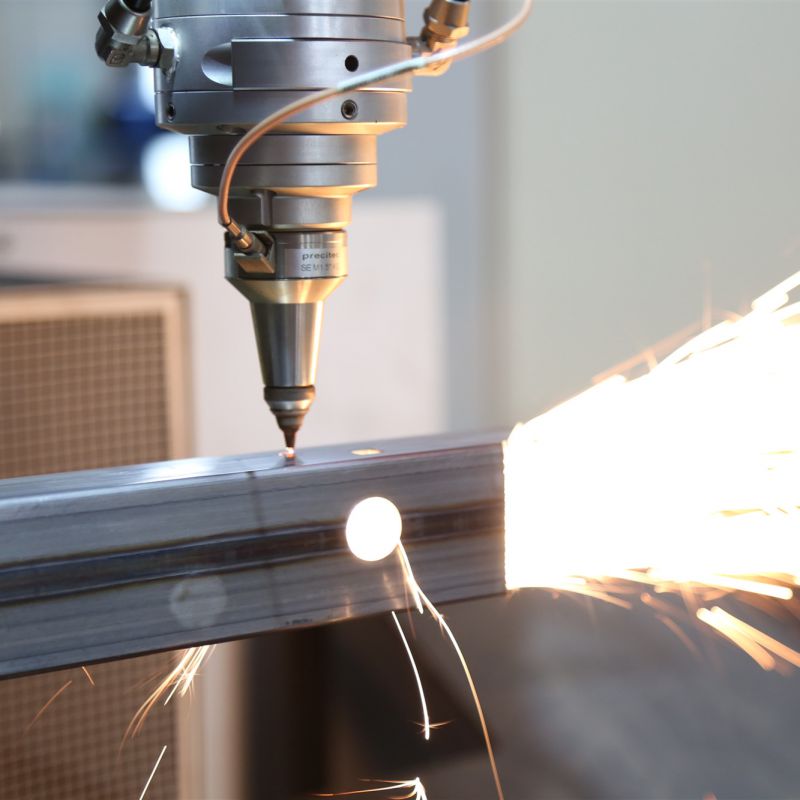

The advent of laser cutting has revolutionized the industrial landscape, reshaping previous concepts of efficiency, accuracy, and productivity. With the continuous advancement and popularity of laser cutting technology, its innovative applications are making waves in various industries. Laser pipe cutting machines, in particular, have the potential to open up a whole new world of design…

Kitchen and bath products are updated rapidly and the market demand is large. Many manufacturers use laser pipe cutting machines, which not only have fast processing speed, high efficiency, and easy operation, but also can complete plate cutting of various shapes without the need for mold or tool replacement, shortening the time. Most kitchen and…

Material cutting is currently the segment with the largest share of laser applications in China, most of which are laser cutting applications of medium and high-power metal materials. Of course, this includes stainless steel, carbon steel, copper, aluminum and other daily major metals, among which stainless steel and carbon steel account for the largest proportion….

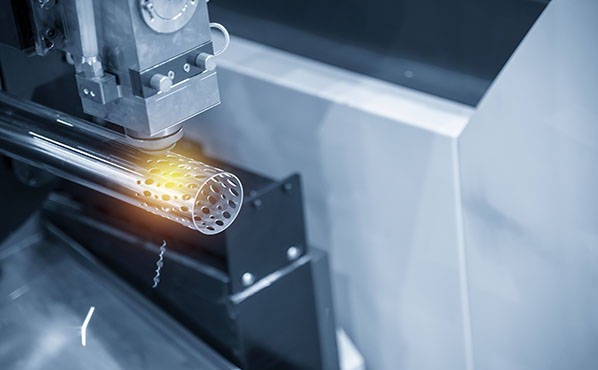

Although the nozzle is an inconspicuous small component, its function is not small. It not only needs to resist the upward rebound of impurities such as molten stains, but also controls the gas diffusion area. Therefore, nozzle’s quality of laser pipe cutting machine is one of the important factors determining the quality of cutting. Today, we will…

The nozzle, also called the copper nozzle, is one of the most important parts in laser cutting. The nozzle is located at the low end of the cutting head of the laser pipe cutting machine. The laser beam and auxiliary gas act on the cutting material through the nozzle. Its main function is to gather…

Specially shaped pipes are pipes with non-circular cross-sectional shapes. Compared with traditional circular pipes, their cross-sectional shapes can be square, rectangular, elliptical, etc., providing a more diverse range of shape choices. The cutting of irregular pipes is quite difficult. Some irregular pipes with complex shapes are difficult to achieve the cutting requirements of high precision,…

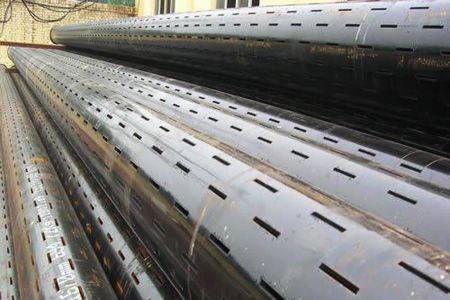

CNC laser pipe cutting machine is a specialized equipment for cutting and processing oil screen pipes. Screen pipe, also known as slotted screen pipe, is a special type of pipe installed at the bottom of seamless or welded steel well pipes in oil wells, water wells, geothermal wells, etc., to separate the extracted liquid from…

HGLaser once successfully developed China’s first large-scale five axis CNC laser pipe cutting machine in just 6 months. The introduction of this pipe cutting machine will end the long history of China’s oil fields importing slotted screen pipes. In 2001, this achievement passed provincial appraisal in Wuhan. It is reported that using slotted screen pipes…

The development of laser tube cutting equipment in China is rapid. According to statistics, in 2020, the cumulative sales volume of high-power CNC laser tube cutting equipment in China reached about 5000 units (sets), with a growth rate of 20% to 30%. However, there are no corresponding national or industry standards, and there are no…