Enterprises must constantly achieve breakthroughs in core technologies, master more key technologies with independent intellectual property rights, and control the leading power of industrial development. Wuhan’s optoelectronic information industry is “unique”, and the biopharmaceutical industry has ranked first in the country. Specialized, refined, and innovative “little giants” have become invisible champions in the global segmented…

HGTECH, a globally recognized leader in cutting-edge laser technology, is set to embark on a remarkable journey throughout November, presenting a showcase of latest innovations and solutions at major international exhibitions. Pakistan Asian International Engineering Machinery Exhibition (IEMA) Date: November 4th to November 6th, 2023 HGTECH’s advanced engineering solutions take center stage at IEMA in Pakistan….

Wuhan Donghu New Technology Development Zone is known as the “China Optics Valley”. It is not only the world’s largest research and production base for fiber optic cables, but also the largest laser industry base in China. Focusing on the major strategic needs of the country, the growth of every leading enterprise in Optics Valley…

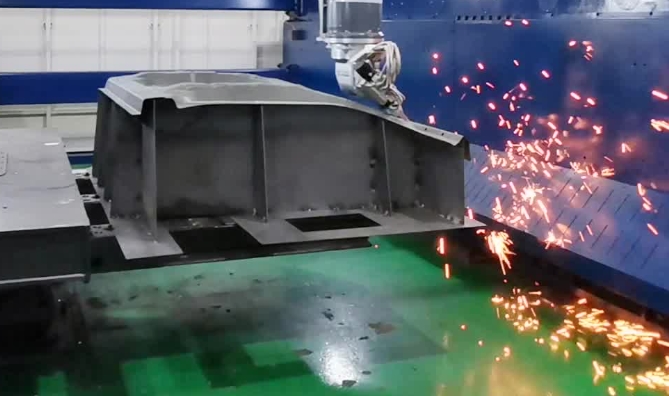

On October 30th, HGTECH’s intelligent manufacturing business, 3D five axis laser cutting intelligent equipment, ushered in an important moment of delivering over 200 units in the hot forming industry. The breakthrough from 1 to 100 units took us nearly 5 years, while from 100 to 200 units, we took less than a year. “Deng Jiake,…

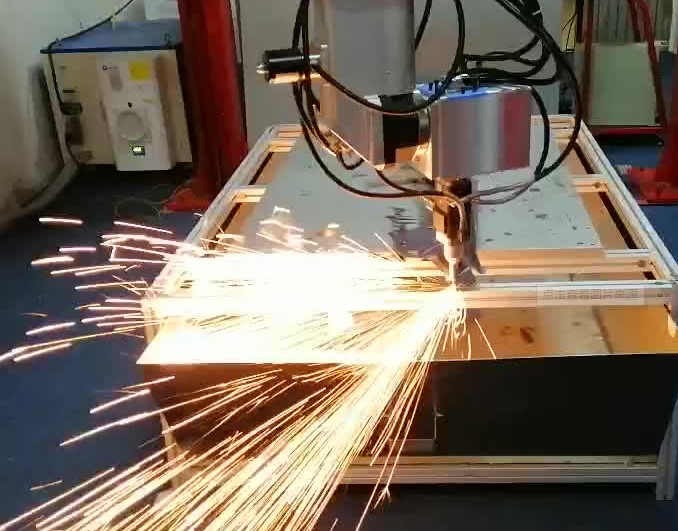

The three-dimensional five axis laser cutting machine is regarded as the pearl on the crown of high-power laser processing equipment. It is mainly used for cutting holes and trimming three-dimensional irregular surfaces, replacing punching and trimming dies. In the early days, manual plasma cutting of three-dimensional workpieces was used in China, but the cutting effect…

Starting again after a 5-year hiatus, the second season of ‘The Great Powers’ hit heavily in 2018. In the second episode of “Launching China,” the 3D five axis laser head technology was grandly exposed. The 3D five axis laser head can process irregular surfaces, which is a 3D five axis laser machine tool. Only industry…

The 3D five axis laser cutting machine is a laser processing equipment for cutting 3D parts with complex curved surfaces. It is mainly used to solve the problem of cutting holes and trimming edges on 3D irregular surfaces, and is used to replace punching and trimming dies. The three-dimensional five axis laser cutting machine has…

Technological Development Trends With the increasingly advanced and advanced 3D laser cutting technology, its performance and functionality are becoming increasingly powerful. The development trend of the technology is as follows: High acceleration, high speed: The product acceleration is getting higher, the product speed is getting faster, and the production efficiency is getting higher and higher;…

The 3D five axis laser cutting machine is a high-end equipment in laser cutting machines, with the process of cutting complex 3D workpieces. It is currently widely used globally and the market demand is increasing. In the 1970s and 1980s, countries such as Europe, Italy, and Japan have successively developed laser 3D machines, and the…

In automobile manufacturing, producing ordinary cars requires 1000-1500 sets of stamping molds, accounting for approximately 40% of the molds required for vehicle production. The traditional direct stamping processing method has caused huge losses to the grinding tools. During the processing, frequent repairs or even replacements are required, resulting in low efficiency and high cost. Laser,…