The medical industry is pushing the gas pedal. The “post-epidemic era” has seen an increase in the construction of the public health system, disease control systems, and primary medical care, as well as a rapid increase in the localization of medical devices. The medical device market has grown at a rate of more than 20%…

MIG, TIG, Laser, and Electron Beam fusion welding processes generate intense heat in a small area to melt the material in the desired weld area. This small heat affected zone is critical because the high thermal conductivity of aluminum causes heat to travel throughout the work piece, melting too much material or deforming the entire…

1. Avoid condensation When summer arrives, the temperature naturally rises, the humidity rises, and the frequent rainfall and humid environment easily cause internal condensation of the aluminum laser cutting machine. Laser maintenance focuses on preventing aluminum laser cutting machine condensation. Don’t let a minor flaw ruin your aluminum laser cutting machine. Separate water cooling controls…

What Types of Metals will Rust? Iron rust is caused by the reaction of oxygen and water in humid air, and it is associated with oxygen and water. It is easy to rust if both are available at the same time. The most common rust phenomenon occurs when iron products have been exposed to air…

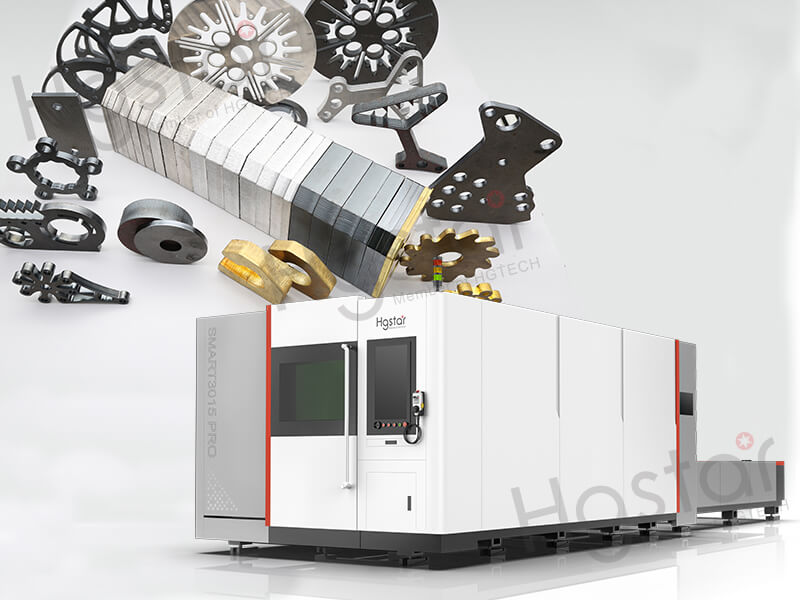

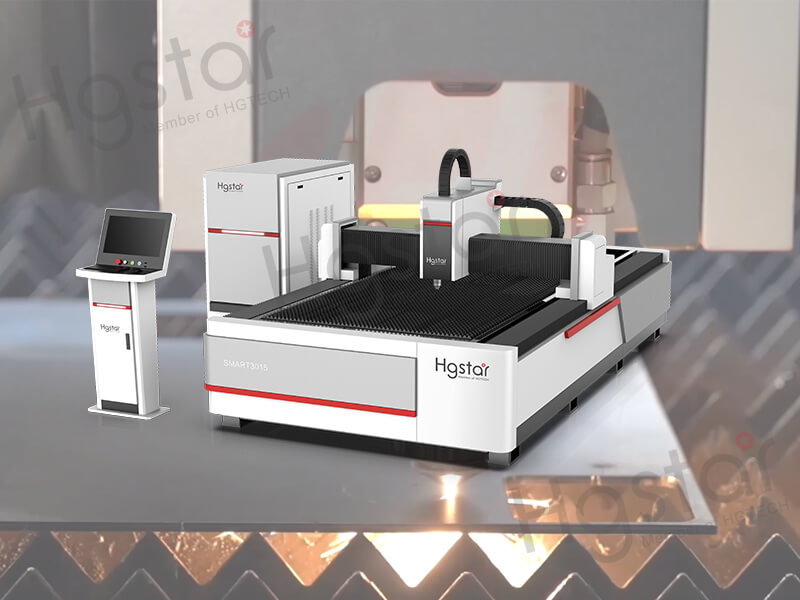

Laser “Intelligent Manufacturing” Expands Into Metal And Medical Markets Metal is processed using the photothermal effect of a laser, which has the advantages of high speed, small surface deformation, high processing precision, and a wide range of processable materials. HGLASER creates an intelligent precision machining ecosystem for metal precision machining by connecting products and technologies…

Can meet the precision parts processing, dynamic performance is stable and lasting. 2. High cut section quality. With the mechanical follower cutting head system, the cutting head follows the height of the sheet while always maintaining the position of the cutting point, resulting in a smooth cutting seam. 3. High performance. Can replace CO2 laser…

As a result, the maximum laser cutting thickness is determined by the specific laser and material used, among other factors. We can combine a 6,000 watt laser with a metal such as stainless steel. In this case, the maximum thickness of the laser cutting would be approximately 2.75 inches. However, the thickness is dependent on…

How does laser cleaning work? Laser cleaning technology works by directing nanosecond-long laser light pulses at a surface. When it interacts with contaminants that absorb laser light, the contaminants or coating particles either turn into a gas or are pushed away from the surface by the pressure of the interaction. Laser cleaning is unrivaled in…

The Main Benefits of Fiber Laser Cutting Fiber lasers have a higher energy conversion rate that can reach up to 30%, saving money on operation and maintenance. The fiber laser metal cutter machine is designed with semiconductor modularity and redundancy, and the resonant cavity lacks an optical lens. As a result, there is no need…

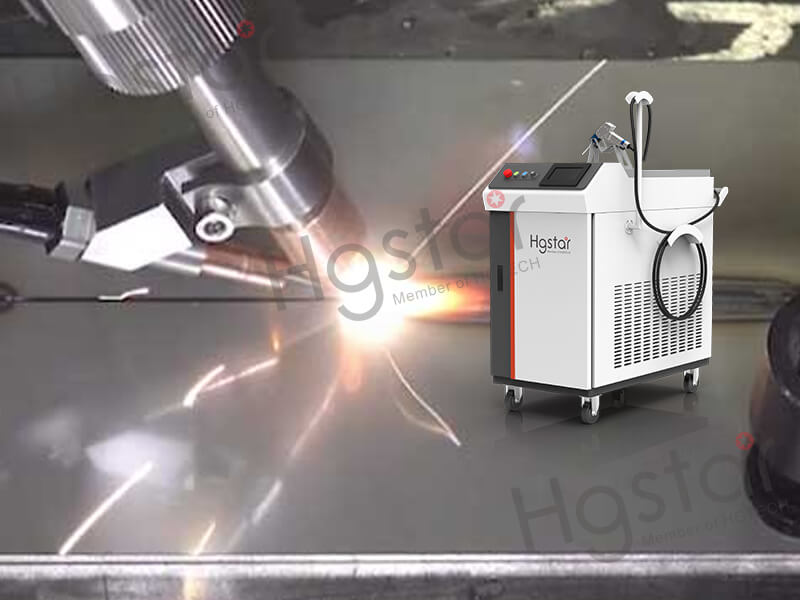

The following are the benefits of using a handheld laser welder: What are the advantages of a hand-held laser welder over traditional welding methods? 1. Simple operation: Manual welding can be performed without the need for costly training. 2. Fast and efficient, wide processing range: Laser welding machines have concentrated energy, high welding efficiency, fast…