IntroductionFiber laser cutting machines, as important equipment in modern manufacturing, have been widely used in various industries due to their high efficiency, precision, and environmental protection characteristics. This article will provide a detailed introduction to the product characteristics and industry of fiber laser cutting machines. Equipment structureThe fiber laser cutting machine mainly consists of laser,…

PrefaceFiber laser cutting machines have advantages in terms of consumables, work efficiency, and cutting effectiveness. Today, let’s talk in detail about the twelve advantages of a 12kw fiber laser cutting machine based on its cutting effect, in order to strengthen our understanding of laser cutting technology. Twelve advantages of laser cutting machines 1. High cutting…

On December 28th, HGTECH successfully delivered the industry’s first optical waveguide glass wafer laser processing intelligent production line to a customer in Shanghai. Building upon extensive R&D experience and addressing the demands of the AR market, HGTECH has launched the industry’s first optical waveguide glass wafer laser processing intelligent production line. This achievement signifies a…

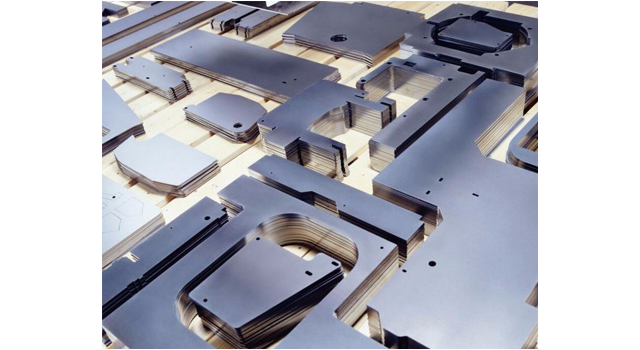

The most advanced cutting equipment With the continuous development of the laser industry, the current use of advanced cutting equipment belongs to fiber laser cutting machines. Fiber laser cutting machines can cut metal sheets and other types of materials, whether it is oblique cutting or circular or square tube cutting, can achieve high-precision results and…

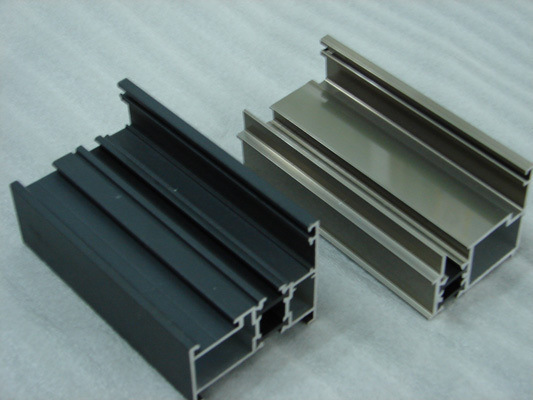

Preface Each component of the fiber laser cutting machine is responsible for different functions and is indispensable. Each component coordinates to complete the cutting action of metal materials. Machine tool The machine tool matched with high-power lasers must be a high-speed machine tool with high dynamic performance. Higher laser power means faster operating speed and…

Improving the processing thickness of 12kw fiber laser cutting machine The revolutionary change that the 12kw fiber laser cutting machine has brought to the field of sheet metal processing is the continuous improvement of the machinability thickness of different materials. Aluminum alloy sheets can reach 40mm, and stainless steel sheets can reach 50mm. Comparison of…

Preface Laser cutting technology is a high-precision material processing method widely used in industries such as metal processing, automotive manufacturing, and electronic equipment. The 12kw fiber laser cutting machine is a common equipment with high power and cutting speed. This article will introduce the process parameters of 12kw fiber laser cutting machine, including beam quality,…

Preface With the improvement of modern industrial equipment production technology, fiber lasers and fiber laser cutting machines have entered the application market, rapidly occupying the market with advantages such as high processing efficiency, good cutting quality, and low operation and maintenance costs. The impact of power increase on laser cutting machines Laser cutting technology is…

Preface Laser technology is becoming increasingly mature, and power is constantly evolving and upgrading towards higher power. Especially in the field of laser cutting, we are moving towards higher power lasers. Many companies are considering purchasing high-power fiber laser cutting equipment and also tend to prefer high-power laser cutting machines. So, what are the advantages…

Preface The high-power large-area fiber laser cutting machine combines the advantages of large cutting width and fast cutting speed, and can cut thicker metal sheets with stable performance. It is an inevitable trend in the development of laser cutting technology. In addition to the advantage of cutting thicker and faster, as the laser power increases,…