The era of myriawatt laser cutting machines has arrived With the pursuit of efficiency and process in the entire processing and manufacturing industry, laser cutting technology continues to make breakthroughs. With its unique advantages such as high power, high efficiency, and high stability, Wanwa laser cutting machines are warmly sought after by the entire industry….

In a landmark event, HGTECH celebrated the grand opening of its cutting-edge manufacturing facility in Shanghe, Jinan on December 15, 2023. The inauguration was graced by the presence of dignitaries, including the Mayor of Jinan, the County Magistrate of Shanghe, the Chairman of HGTECH, the General Manager of HGLaser, and the General Manager of HGstar….

Preface The current socio-economic level is constantly improving, and the mechanical processing industry is developing rapidly. Laser cutting technology, as an important technology in mechanical processing, has achieved good application results, especially for the processing of hard metal materials. The use of laser cutting technology can significantly enhance the efficiency and quality of mechanical processing,…

Preface In the previous issue, we talked about the operation steps of laser cutting equipment for cutting metal. Proper operation of metal laser cutting machines can fully utilize their excellent cutting efficiency, and they can effortlessly handle even thick metal materials. Today, let’s talk about how many people overlook the principles and shutdown steps of…

Preface Metal materials are important products in the manufacturing industry. To fully utilize this material, it must be cut and formed using equipment, and laser cutting machines are important mechanical equipment in the metal forming industry. Compared to other types of cutting machines, laser cutting machines have a higher degree of automation, a wider range…

Preface There are countless application cases of laser cutting machines in metal material processing. Due to their high work efficiency and high cutting quality of finished products, they have become standard equipment in metal sheet processing stations. But some customers may experience slight burrs on the front and back surfaces of the sub materials when…

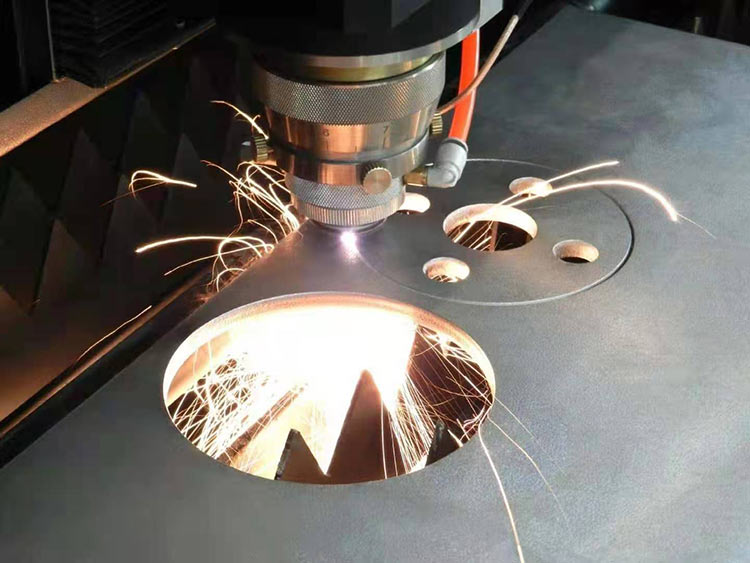

The workflow of laser sheet cutting machine Laser cutting is the process of combining the laser emitted from a laser into a high-power density laser beam through an optical path system. With the assistance of a laser cutting system, the laser beam is precisely irradiated onto the surface of the workpiece, causing it to reach…

Preface In modern manufacturing, laser cutting equipment has become the first choice for most manufacturers. However, as traditional cutting equipment, it still holds a considerable market share. The commonly used traditional cutting processes in the market now mainly include plasma cutting and high-pressure water cutting. This article mainly discusses laser cutting, plasma cutting, and high-pressure…

Preface In modern manufacturing, although laser cutting equipment has become the first choice for most manufacturers. However, as traditional cutting equipment, it still holds a considerable market share in the market. Traditional cutting equipment mainly includes (CNC and non CNC) shearing machines, punching machines, flame cutting, plasma cutting, high-pressure water cutting, and other means. This…

Preface In modern manufacturing, an important process is metal cutting. When traditional processing methods can no longer meet the current cutting needs, laser cutting equipment has become the first choice for most manufacturers. Principles of Laser Cutting The cutting principle of laser cutting equipment is to focus the laser emitted from the laser into a…