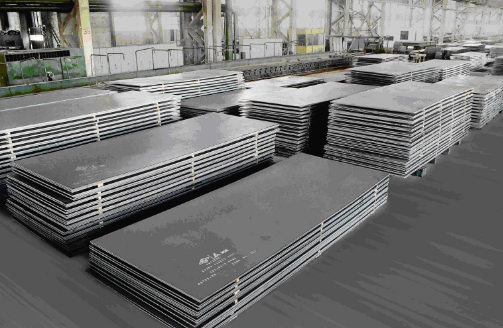

H-shaped steel is an economical cross-section and high-efficiency profile with more optimized cross-sectional area distribution and more reasonable strength-to-weight ratio. It is named because its cross-section is the same as the English letter “h”. Since all parts of H-shaped steel are arranged at right angles, H-shaped steel has the advantages of strong bending resistance in…

On October 19th, HGTECH and Shanghai Waigaoqiao Shipbuilding Co., Ltd. held a strategic cooperation signing ceremony. The event saw the signing of a strategic cooperation agreement by Jin Yu, Party Committee Member and Chairman of the Technology Committee of Shanghai Waigaoqiao Shipbuilding Co., Ltd., and Xiong Wen, Party Committee Member and Vice President of HGTECH….

H-shaped structural steel is widely used in construction, industry, shipbuilding and other fields. It has the characteristics of light weight, good stiffness, excellent quality and convenient construction. At present, the commonly used cutting processes for H-shaped steel include manual flame cutting and CNC flame cutting. However, there are problems such as low cutting accuracy, uneven…

On October 18th, Huagong Tech Company Limited (referred to as ‘HGTECH’) and Shanghai Zhenhua Heavy Industries Group Co., Ltd. (referred to as ‘ZPMC’) signed a strategic cooperation framework agreement. The signing ceremony was attended by the Party Secretary of ZPMC, Hui Kai; the Party Secretary and Chairman of HGTECH, Ma Xinqiang; the Vice President of…

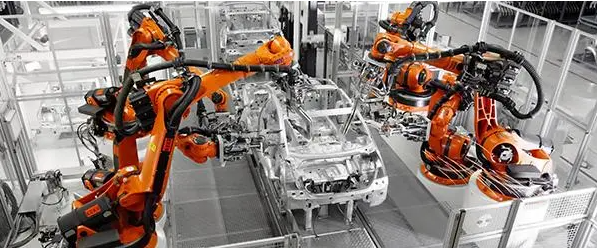

In the automotive industry, where advanced technologies are most concentrated, lasers are reflecting their growing presence with bright light. Taking automotive panel processing as an example, the laser blanking line is one of the most widely used and popular processing methods at the moment. Why does laser blanking attract so much attention and become the first…

Laser technology is becoming increasingly mature, and its power is constantly developing and upgrading towards higher power. Especially in the field of laser cutting, we are moving towards higher power lasers. Many companies are considering purchasing high-power fiber laser cutting equipment and will also tend to use high-power laser cutting machines. So, what exactly are…

The laser cutting technology is cleverly combined with the coil unwinding and feeding technology, and the “three-head linkage technology” of the system controlling the laser cutting head is used to perform dynamic flight cutting on the laser cutting platform, replacing the traditional press and mold, and realizing the cutting of metal strips. Automatic blanking, and…

The focus on vehicle lightweighting has ushered in the introduction of new materials and metal grades, which has increased the use of advanced high-strength steels (AHSS) with tensile strengths of 750MPa and above. Forecasts show that high-strength steel will account for 40% of body materials around 2025. AHSS allows automakers to reduce vehicle weight compared…

The coil laser blanking line is an automated production line that uses leveling and servo feeders to feed the coil into the machine for blanking processing. This kind of production line is usually used for the production of ceiling doors and windows, automobile sheet metal and other metal materials. The use of coil laser blanking…

In the realm of manufacturing, structural steel plays a pivotal role, finding extensive applications in various construction and manufacturing endeavors. HGTECH’s structural steel cutting equipment not only enhances the efficiency and precision of structural steel processing but also reduces costs, paving the way for a more sustainable future in manufacturing. Structural Steel: The Cornerstone of Building the…