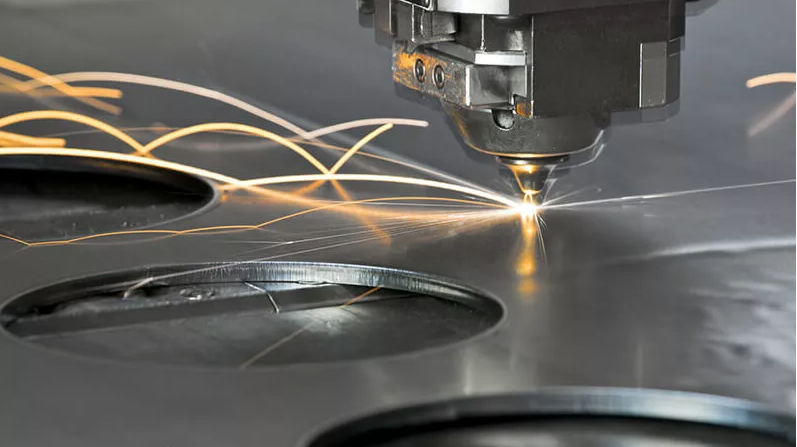

Laser, born in the 20th century, has become the core driving force of laser cutting technology through continuous development and application. With the modern industrial revolution, laser cutting technology has become a high-tech application technology. Through computer program control, it presents the advantage of flexible processing, greatly replacing the mold stamping process in traditional cutting…

The growth rate of the laser processing market has further slowed down, and the maturity of some application markets and the competition in the Red Sea have also made relevant enterprises face the dilemma of increased operating pressure and declining performance. The COVID-19 in 2020 has cast a shadow on the development of laser enterprises….

Current Development Status of New Energy Vehicles In 2021, the sales of new energy vehicles in China reached a historic breakthrough of 3.5 million units, with a growth rate of 157.5%. At the same time, the market share continued to increase, reaching 13.4% in 2021; New energy vehicles have become an important increment in China’s…

What are the social impact environments for the development of five axis lasers? Widespread demand brought by downstream applications The 3D five axis laser cutting technology has been around since the 1990s, and the initial market demand was not high. But with the emergence and application of automotive hot forming technology, the situation of low…

Industrial cleaning can generally be divided into physical cleaning and chemical cleaning. Among them, physical cleaning mainly utilizes the principles of mechanics, acoustics, optics, electricity, and heat, relying on the action of external energy to remove surface dirt without changing the composition of the dirt. Among numerous cleaning methods, laser cleaning is an emerging method….

The ability to convert scientific research achievements into commodities is poor, and many promising achievements remain in the prototype stage of the laboratory; The core component of laser processing systems is a limited variety of lasers, outdated technology, and poor reliability. There is little research on processing technology, especially on fine processing technology, and there…

In 2022, the production and sales of China’s power battery industry were 545.9GWh465.5GWh, with a year-on-year increase of more than double. In 2023, new production capacity of power battery manufacturers will gradually be released, driving further growth in China’s power battery production. According to data from the Battery Alliance, the production of power batteries in…

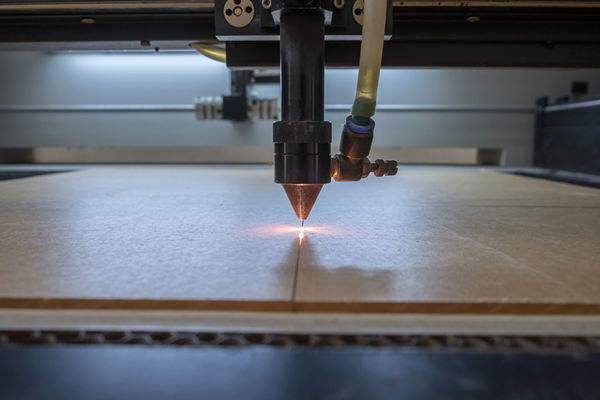

Nowadays, advocating for green and environmental protection, many people choose to travel by bike. However, when you walk on the street, the bicycles you see are basically the same appearance and have no distinctive features. Have you ever thought about owning a bicycle that belongs to your own personality? In this high-tech era, laser cutting…

Classification of Laser Cleaning Technology The methods of laser cleaning can be mainly divided into the following three categories: 1.Laser dry cleaning Laser radiation is used for direct decontamination. After the laser is absorbed by objects or dirt particles, vibration is generated, resulting in the separation of the substrate and pollutants. There are two main…

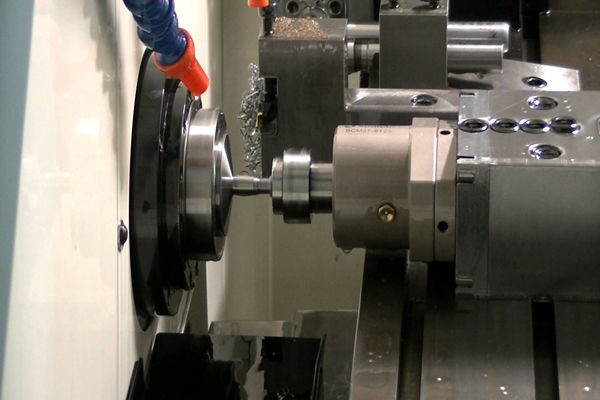

The three-dimensional five axis fiber laser cutting machine is regarded as the pearl on the crown of high-power laser processing equipment, mainly used for cutting holes and trimming three-dimensional irregular surfaces, replacing punching and trimming molds. In the early days, manual plasma cutting of three-dimensional workpieces was used in China, but the cutting effect was…