Generally, the thickness of capacitor shells is required to be less than 1.0mm. Currently, mainstream manufacturers mainly use 0.6mm and 0.8mm shell material thicknesses based on different battery capacities. The welding methods are mainly divided into side welding and top welding, and the main advantage of side welding is that it has less impact on…

PCB is one of the important electronic components in the electronic industry. Almost every electronic device, such as electronic watches, calculators, computers, communication electronic devices, military weapon systems, etc., requires the use of printed circuit boards for electrical interconnection as long as there are electronic components such as integrated circuits. PCB has evolved from single…

In the field of industrial applications, laser cleaning objects are divided into two parts: substrate and cleaning material. The substrate mainly includes surface pollution layers of various metals, semiconductor chips, ceramics, magnetic materials, plastics, and optical components. The cleaning material mainly includes a wide range of application requirements for industrial fields such as rust removal,…

Laser cleaning is a green non-destructive surface cleaning technology that utilizes the interaction between laser and material to remove attachments on the substrate surface. The quality and efficiency of laser cleaning are influenced by the interaction of multiple parameters. When other parameters are the same, the higher the peak power, the higher the peak power…

PCB and FPC are important components and circuit connection carriers in the 3C industry. With the continuous development of intelligence in the electronics industry, PCBs and flexible circuit boards (FPCs) are becoming smaller and thinner, accommodating more and more electronic components, and requiring higher machining precision. At the same time, the application of lasers on…

In 1969, Beadair et al. first proposed the concept of laser cleaning. Laser cleaning technology has the advantages of good cleaning effect, wide application range, high precision, non-contact and reachability. It is in sharp contrast with cleaning methods of detergent, ultrasonic and mechanical methods. It is expected to partially or completely replace traditional cleaning methods…

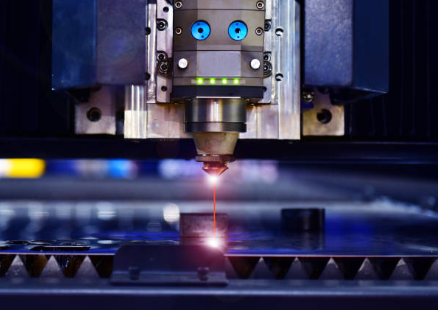

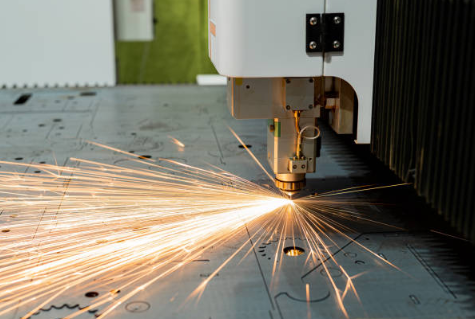

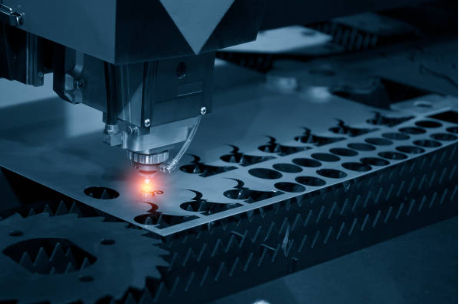

Laser cutting is the use of a high-power density laser beam to scan the surface of a material, heating the material to thousands to tens of thousands of degrees Celsius in a very short time, melting or vaporizing the material, and then using high-pressure gas to blow the melted or vaporized material away from the…

The competition in the automotive market is becoming increasingly fierce, and the interior design is becoming increasingly diverse. The processing technology is also constantly upgrading, and more interior designs are produced using laser technology, which is also widely used. Compared to traditional manufacturing technologies, laser technology has many advantages and plays an increasingly important role…

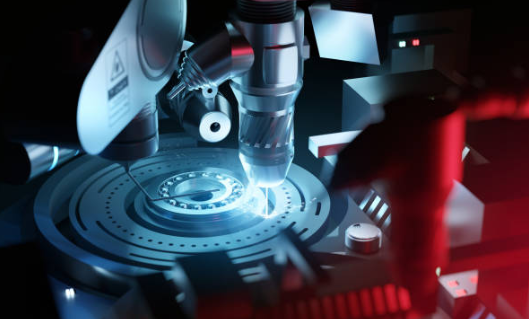

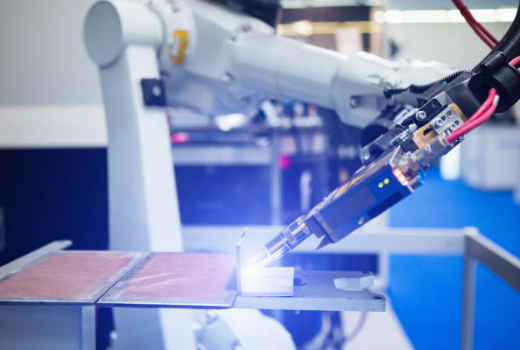

Laser welding is an efficient and precise welding method that uses a high-energy density laser beam as the heat source, with advantages such as high efficiency, accuracy, simplicity, and ease of use. Nowadays, laser welding has been widely applied in various industries, such as electronic parts, automotive manufacturing, aerospace and other industrial manufacturing fields. However,…

Metal laser cutting machine is a type of machine equipment that uses metal to create and laser technology to cut metal. Nowadays, many metal processing manufacturers choose to use laser cutting machines to cut metal. The advantages of metal laser cutting Metal laser cutting is an important production process in the industrial construction industry. At…