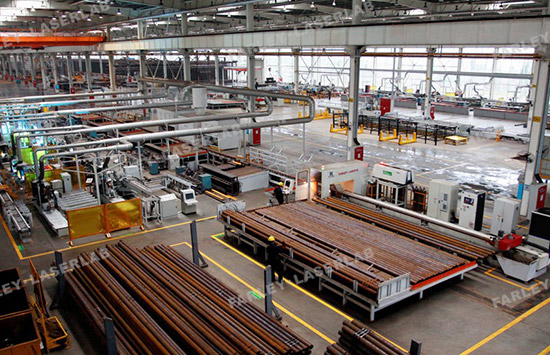

Introduction The coil fed laser punching line is a sheet metal processing equipment suitable for uncoiling, cleaning, oiling, leveling, feeding, and stacking surface covering plates in industries such as automobiles and steel plate distribution. It has been widely used among automobile manufacturers in developed countries. Production mode of laser uncoiling and material cutting Laser cutting…

Preface The global automotive industry has undergone significant changes, and with the increasing call for energy conservation, emission reduction, and improved driving experience, a trend of “lightweight” has emerged in the automotive manufacturing industry. Reducing self weight to achieve lightweight of automobiles has become a breakthrough point for major automotive companies, which has put forward…

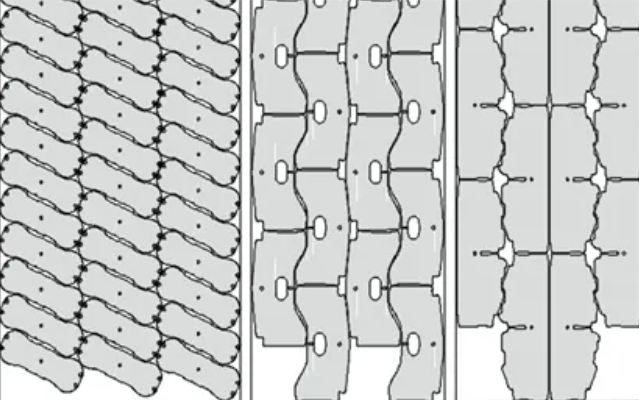

Introduction With the maturity of coil fed laser cutting technology, mainstream domestic and foreign car companies have begun to use coil fed laser cutting lines to produce inner and outer plate blanks. The coil laser cutting machine is particularly suitable for the cutting of high-strength steel automotive inner panels and the drilling and edge cutting…

Laser processing technology for automotive applications The automotive industry is one of the most widely used fields for laser processing. In developed industrial regions such as Europe and America, 50% -70% of automotive components are manufactured using laser processing technology. In industrialized countries, there are over 30000 laser processing equipment used in the automotive industry…

Introduction With the increasing severity of global climate change and resource scarcity, the development of new energy vehicles, especially the trend of vehicle lightweighting, has become an irreversible trend in the automotive industry. This consensus not only stems from the demand for environmental protection, but also from the inevitable result of technological progress and market…

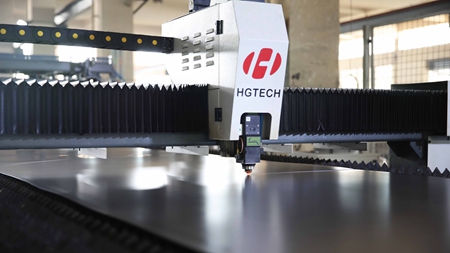

Recommended models for coil fed laser cutting lines The HGTECH high-speed laser intelligent uncoiling and discharging line equipment consists of a loading trolley, uncoiler, plate cleaning machine (expandable configuration), leveling machine, buffer loop, guide and servo feeding machine, laser cutting machine, part cleaning device (expandable configuration), automatic sorting and stacking device (expandable configuration), waste treatment…

Laser technology advancement leads industry transformation In recent years, fiber laser technology has rapidly emerged, occupying a place in the field of laser processing with its unique advantages. Unlike traditional solid or gas lasers, fiber laser has higher brightness and more stable performance. The highly concentrated light of fiber laser is particularly suitable for fast…

Introduction The advantage of coil fed laser cutting lines not only in their widespread application, but also in their high efficiency and precision. The Intelligence of Laser Cutting Technology Laser cutting technology has the characteristics of non-contact, non-destructive, and high-precision. The heat affected area generated during the cutting process is very small, which has a small…

Introduction Laser technology, as one of the most advanced manufacturing and processing technologies in the world today, has been widely applied in industrial production, communication, information processing, medical beauty, 3D sensing, military, cultural education, and scientific research. In the previous article, we talked about the advantages of laser cutting production lines. Today, we will learn…

IntroductionIn the previous article, we talked about the trend of customization and intelligence in laser equipment. We know that laser is another major invention of humanity since the 20th century, known as the “fastest knife,” “most accurate ruler,” “brightest light,” and “strange laser.”. Laser technology, as one of the most advanced manufacturing and processing technologies…