With the development of science and technology, electronic, electrical and digital products have become increasingly mature and popular all over the world. Any components contained in the products covered in this field may involve the soldering process, ranging from the main PCB components to the VCM components in the camera module. Most of them need…

China’s sports industry in the post-epidemic era is about to enter a new growth cycle of dual innovation at the competitive and commercial levels. The blueprint of the “14th Five-Year Plan” for building a sports power contains a major opportunity to expand sports consumption and develop sports industry. With the continuous development of the sports…

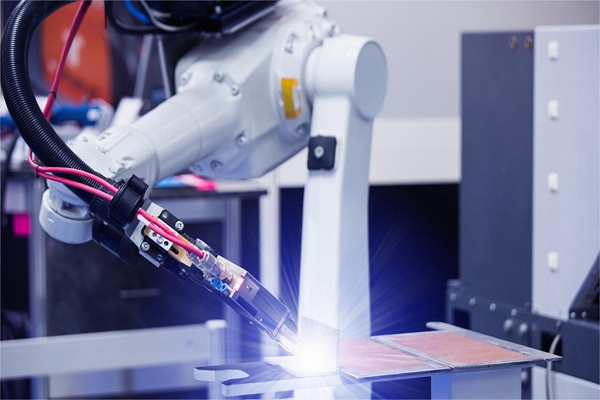

Laser cutting robot has the characteristics of high cutting accuracy, fast cutting speed, narrow cutting seam, high cutting quality, good flexibility, high flexibility and stable performance. Laser cutting robot is the product of combining laser cutting technology with robot technology. Laser cutting is to gather the high power density laser beam into a small light…

They stick to the front line and say goodbye to their families to go overseas. They shoulder their responsibilities with their actions. In Korea, in Thailand, in Vietnam, in Europe …… you can see the busy, hard-working HGTECHER everywhere. In Korea, HGTECH’s hg350 project lasted for 1.5 years, with a permanent staff of 11 people….

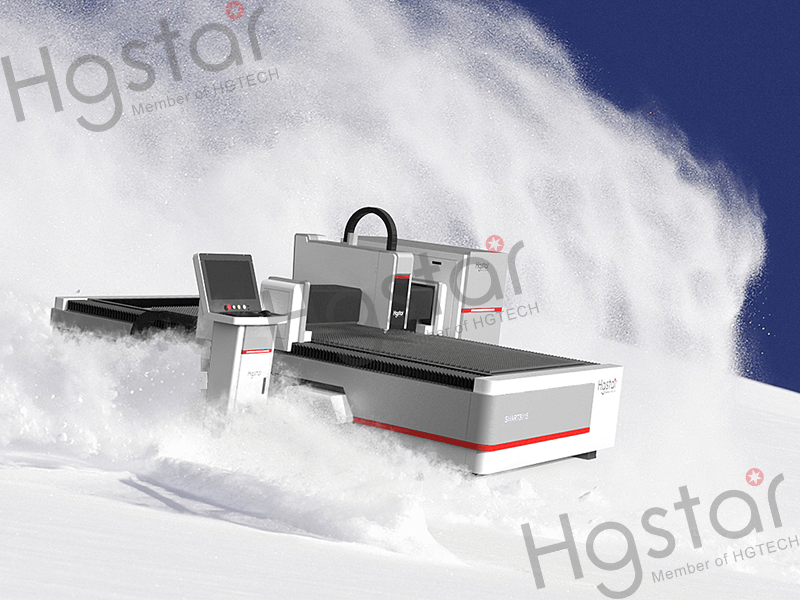

Dear customers: Thank you very much for choosing HG STAR’s laser equipment! As winter approaches and temperatures drop, our equipment needs to be protected from water cooler and laser source malfunctions. Damage caused by environmental factors or failure to take proper protective measures is not covered by the warranty, so we would like to send…

How to choose your own laser rust removal machine With the rapid development of laser cleaning technology, laser rust removal machines have progressively entered people’s lives with their distinctive benefits of little damage, high cleaning accuracy, zero emissions, and pollution-free. There is little doubt that the use of laser cleaning technology to remove grime from…

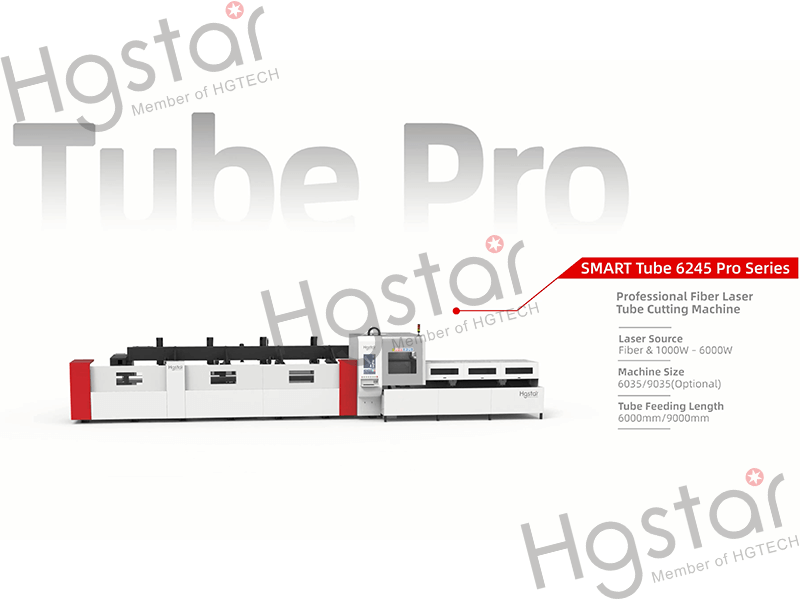

What Is tube cutter laser? The procedure and technique used to cut tubes, structural shapes, or channels is known as tube cutter laser. These products will be chopped to the required length during the process. It can also make holes or decorations in tubing. It is a precision cutting method. It can also be used…

Lazer cutting is a fabrication process that utilizes a high-powered laser beam on a lazer cutting machine to cut the material into various shapes and designs. The laser cutting process is suitable to cut a wide range of materials including metal, plastic, wood, gemstone, glass, and paper. A key benefit of laser cutting is that…

The heat produced by a laser beam directed by mirrors or optical fibers is used by laser cutting equipment. You can cut a variety of materials using different types of lasers. Typically, CO2 laser cutting equipment are used to cut soft steel, wood, glass, foam, plastic, and foam. Copper and brass, which reflect light, cannot…

Laser processing technology is now being applied and promoted at a rapid pace, and laser manufacturing can be found in various industrial fields. In the mold industry, laser cleaning has huge advantages over traditional surface cleaning. Injection molding, die-casting, stamping, stretching and other initial product forming are all dependent on the mold to complete, and…