During the use of electronic circuit boards, small particulate pollutants attached to them can cause short circuits or performance degradation in integrated circuits, and even damage components. Traditionally, water washing and ultrasonic cleaning methods are used, but water washing cannot remove particles of several microns, and ultrasonic waves are prone to damage components. With the…

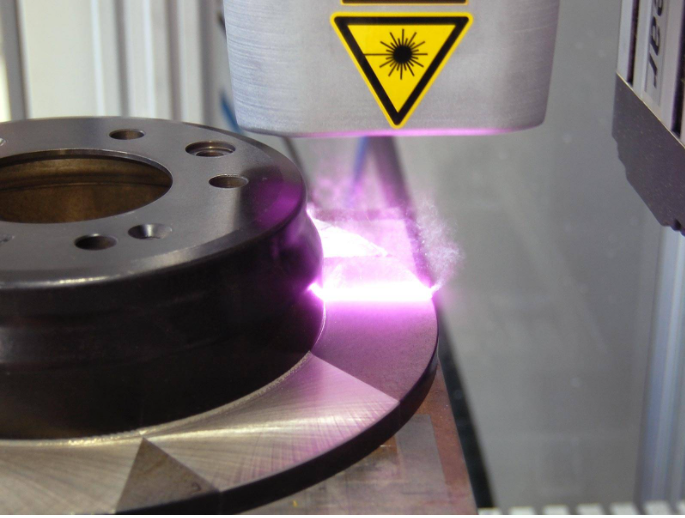

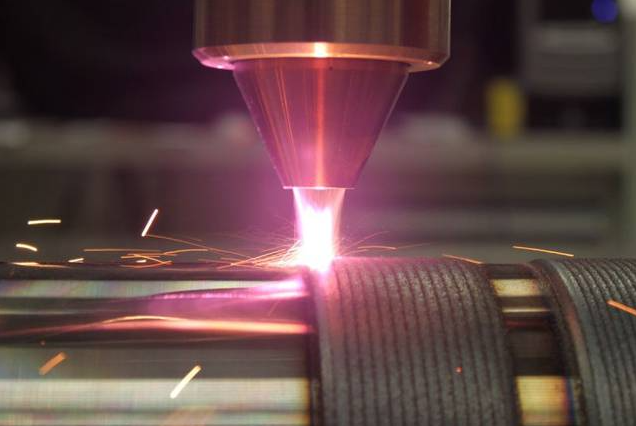

Laser cladding uses a high-energy laser as a heat source and alloy powder as a cladding material. By irradiating the alloy powder with laser beam and simultaneously acting on the surface of the workpiece, it quickly melts to form a molten pool, and then rapidly solidifies to form a dense, uniform, and controllable thickness metallurgical…

Increase of market demand for high-quality plastic welding Laser plastic welding is increasingly widely used in many industrial fields, including medical, automotive and electronic packaging. The connection demand between plastics and plastics, plastics and metals will continue to promote the development of the global laser plastic welding market. There are more and more applications of…

Under the current development trend, the market’s demand for mobile phone functions tends to be diversified, especially in terms of cameras. Good requirements for photography, sensitivity, depth focus and so on have made three cameras and four cameras popular. Moreover, the short board of CNC (Computer numerical control) processing has become increasingly prominent, and laser…

Stainless steel is a very common material in our life and production. With the continuous expansion of the stainless steel market, thin stainless steel is widely used in kitchenware, bathroom, small household appliances, doors and windows and other industries. As the stainless steel plate goes deep into various fields of production and manufacturing, the welding…

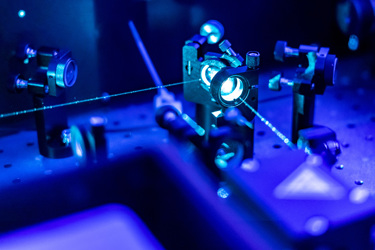

Now the reliability and repeatability of laser processing have enabled manufacturers to produce higher quality with higher efficiency. Quantity of parts. From sintering in additive manufacturing to parts processing in electric vehicles, the industry is developing new applications of laser technology every day. With the development of laser technology, laser processing becomes more stable, reliable…

Laser cleaning is a surface engineering technology that uses the high energy characteristics of laser to remove the attachments on the surface of the substrate. At present, it has been demonstrated and applied in the fields of mold, shipbuilding, machining and aerospace. As a pillar industry of the national economy, most manufacturers of laser cleaning…

The importance of wheels in the operation safety of metro vehicles Due to the high efficiency and capacity of railway transportation, railway transportation has been established as one of the most important alternatives to reduce traffic congestion, especially in urban areas. Although there has been no major or serious safety accident, the development of industry…

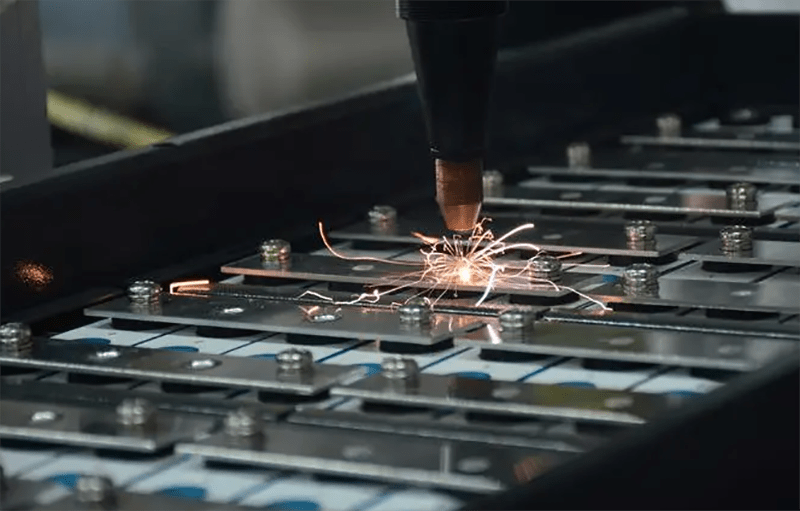

Laser welding belongs to melting welding, which uses the laser beam as the energy source to impact on the weldment joint. Laser welding is non-contact welding, which does not need to be pressurized during operation, but inert gas is required to prevent oxidation of the molten pool, and filler metal is occasionally used. Laser welding…

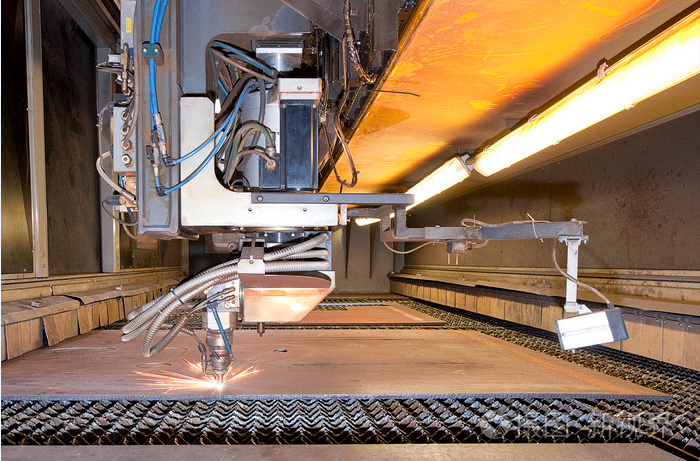

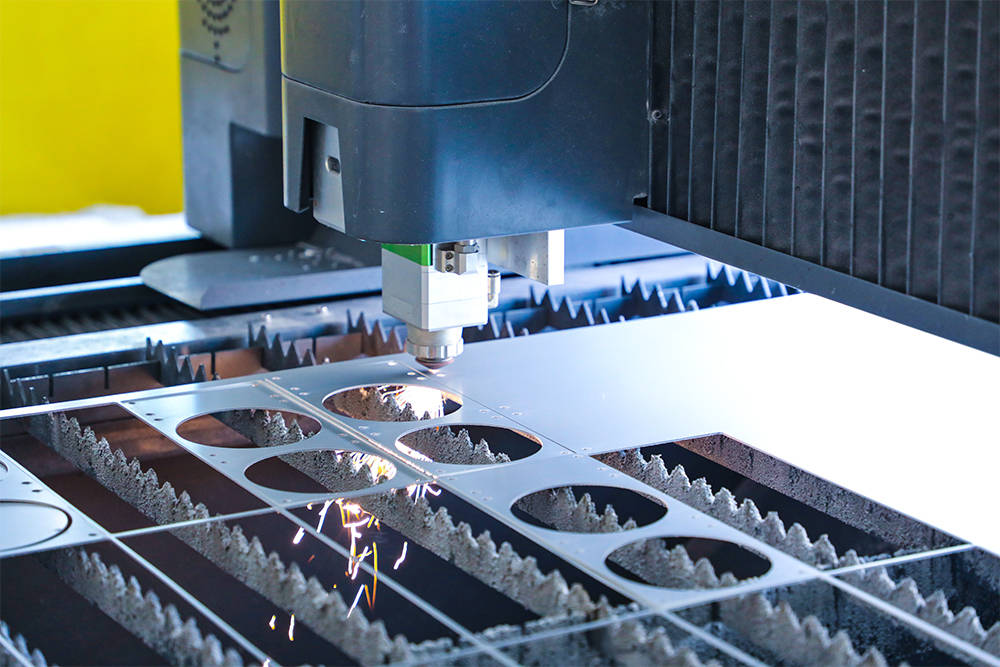

It is obvious that people want to make money with laser cutting machines. Many people believe that increasing the power of lasers will increase their income – sometimes it is, but sometimes it is not. If we consider how increasing power will affect income, then we should discuss this issue in detail. When the power…